4

and depressurized for servicing. Bypass piping may be in-

stalled around the dryer for uninterrupted airflow when the

dryer is serviced. If the compressed air operation cannot

tolerate undried air for short periods, install a second dryer

in the bypass line.

Compressed air systems commonly require filters to re-

move compressor oils, particulates, condensed liquids and

other contaminants. When an oil-removal filter is used, in-

stall the filter downstream of the refrigerated dryer. At this

location, the life of the replaceable filter element is pro-

longed since some of the entrained oil is removed by the

dryer and drained through the separator.

Ammonia contamination may cause problems within the

dryer heat exchanger. If ammonia is present in the air-

stream, consult your local distributor for recommendations.

Piping and Connections

Piping must be furnished by the user unless otherwise

specified. Connections and fittings must be rated for the

maximum operating pressure given on the dryer data plate

and must be in accordance with applicable codes. Support

all piping; do not allow the weight of any piping to stress the

connections of the dryer or filters. Piping should be at least

the size of the inlet and outlet connections to minimize pres-

sure drop in the air system. See Table I for dryer inlet and

outlet connections.

Drains

Condensate must be drained from the dryer to prevent its

reentrainment. The dryer is equipped with an automatic

drain valve.

The user must install a discharge line for the drain valve

and run the line to an environmentally-approved conden-

sate collection/disposal system. Pipe or copper tubing ½-

inch or larger is recommended for condensate discharge

line. Do not use ¼-inch or -inch O.D. flexible tubing unless

the discharge line is shorter than 10 feet. Install the dis-

charge lines so that condensate can be seen as it drains.

Cooling Water

Cooling water is required for water-cooled refrigerant con-

densers. The user is responsible for piping the water to

and from the condenser. A factory-installed water regulat-

ing valve in the condenser inlet connection is standard.

The required water flow rate depends on the water tem-

perature (refer to Table II). A valve supplied with the dryer

automatically adjusts the flow to compensate for variations

in water temperature, water pressure and dryer air load.

Operating the dryer with inadequate condenser cooling wa-

ter (temperatures above or pressures below those in Table

II) will cause a rise in dew point unless the dryer inlet air-

flow is reduced. The refrigerant discharge pressure control

will shut down the refrigerant compressor if cooling water

is inadequate.

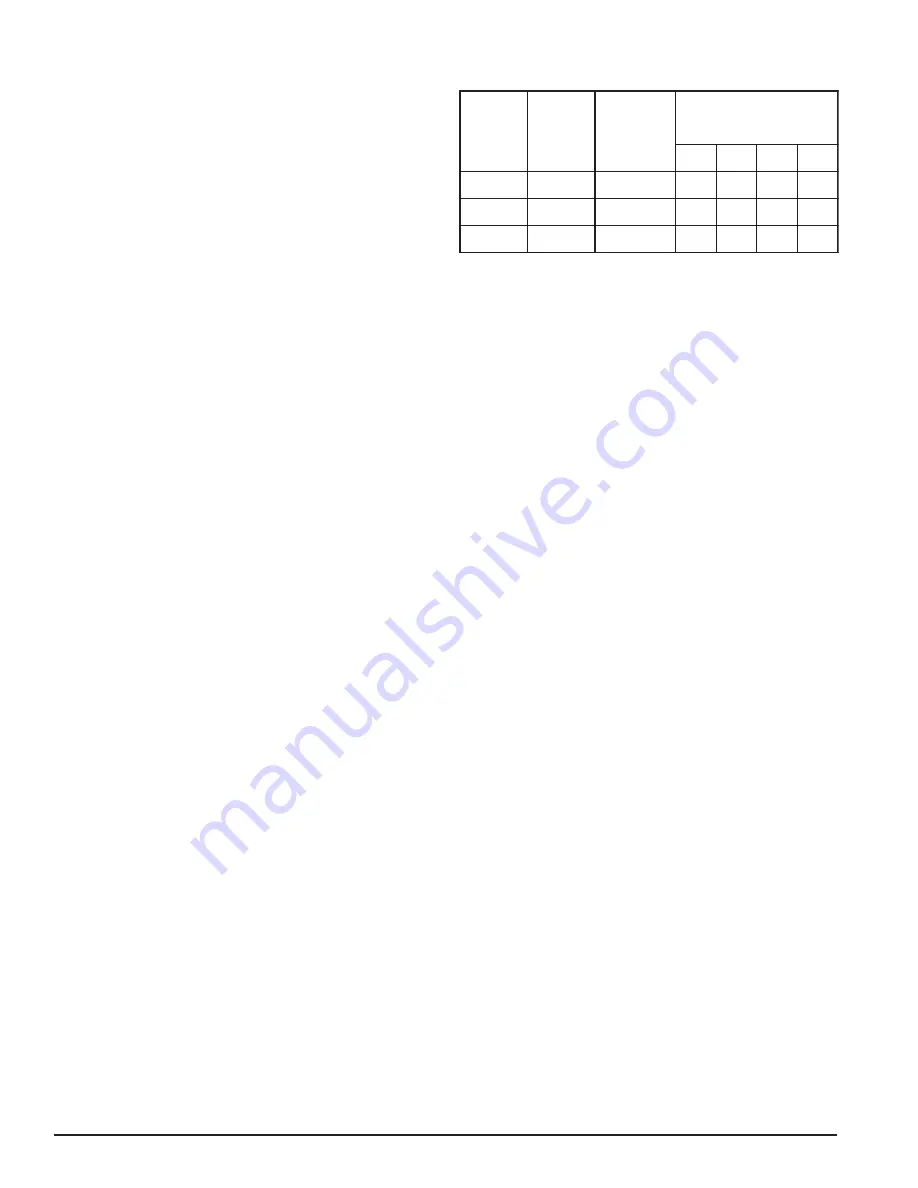

Table 2

COOLING WATER REQUIREMENTS

a

R

E

Y

R

D

L

E

D

O

M

N

N

O

C

S

E

Z

I

S

s

e

h

c

n

i

(

)

T

P

N

b

T

A

E

H

N

O

I

T

C

E

J

E

R

)

r

h

/

U

T

B

(

D

E

R

I

U

Q

E

R

R

E

T

A

W

G

N

I

L

O

O

C

)

m

p

g

(

W

O

L

F

c

F

°

0

7

F

°

0

8

F

°

5

8

F

°

0

9

W

0

0

8

¾

5

8

0

,

1

4

—

—

0

.

4

0

.

6

W

0

0

0

1

¾

9

8

2

,

0

5

—

—

5

.

5

0

.

9

W

0

0

2

1

¾

4

4

1

,

9

9

—

—

5

.

5

5

.

8

a

Minimum water pressure is 25 psig for city water and 35 psig for tower

water. Maximum water pressure is 150 psig. Temperature rise across

the condenser is approximately 10°F.

b

Inlet and outlet connections are the same size NPT.

c

Contact factory if available cooling water is higher than 90°F.

Note:

Cooling water pressures below or temperatures above those listed

in Table II may reduce drying capacity. The refrigerant discharge pres-

sure control will shut down the refrigerant compressor if cooling is inad-

equate.

Water Quality Recommendations

Water quality is often overlooked when the cooling system

of a water-cooled dryer is examined. Water quality deter-

mines how effective the heat transfer rate and flow rate will

remain during the dryer’s use. The quality of water used in

any cooling system does not remain constant during the

operation of the system. The water makeup is affected by

evaporation, corrosion, chemical and temperature changes,

aeration, scale and biological formations. Most problems

in a cooling system show up first in a reduction in the heat

transfer rate, then in a reduced flow rate and, finally, with

damage to the system.

If the cooling water is dirty, install a strainer ahead of the

condenser inlet. Install shutoff valves so that the strainer

can be drained and cleaned at regular intervals. There are

many constituents in the water system that must be bal-

anced to have a good stable system. The following are the

major components that should be monitored:

Corrosion

Corrosion problems may be caused by: chlorides, low pH

levels and high levels of dissolved oxygen. These condi-

tions should be monitored and treated as necessary to pre-

vent corrosion.

Scale

Scale formation will help to prevent corrosion. Therefore, a

thin uniform coating of calcium carbonate is desired on the

inner surfaces of the cooling system. However, in excess,

scale formation will inhibit effective heat transfer.

One of the largest contributors to scale formation is the

precipitation of calcium carbonate out of the water. This is

dependent on temperature and pH. The higher the pH value,

the greater the chance of scale formation. Scale can be

controlled with water treatment.

Summary of Contents for RCD800

Page 27: ...27 NOTES...