4-3

< Tuning procedure >

1) Preparation

Check the rating plate on the motor and set the following function codes to their nominal

ratings:

• F04 and A02: Base frequency

• F05 and A03: Rated voltage at base frequency

• P02 and A16: Motor rated capacity

• P03 and A17: Motor rated current

2) Selection of tuning process

Check the situation of the machine system and select either "Tuning while the motor is

stopped (P04 or A18 = 1)" or "Tuning while the motor is running (P04 or A18 = 2)." In the

case of "Tuning while the motor is running (P04 or A18 = 2)," also adjust the acceleration

and deceleration times (F07 and F08) and set the rotation direction properly so that it

matches the actual rotation direction of the machine system.

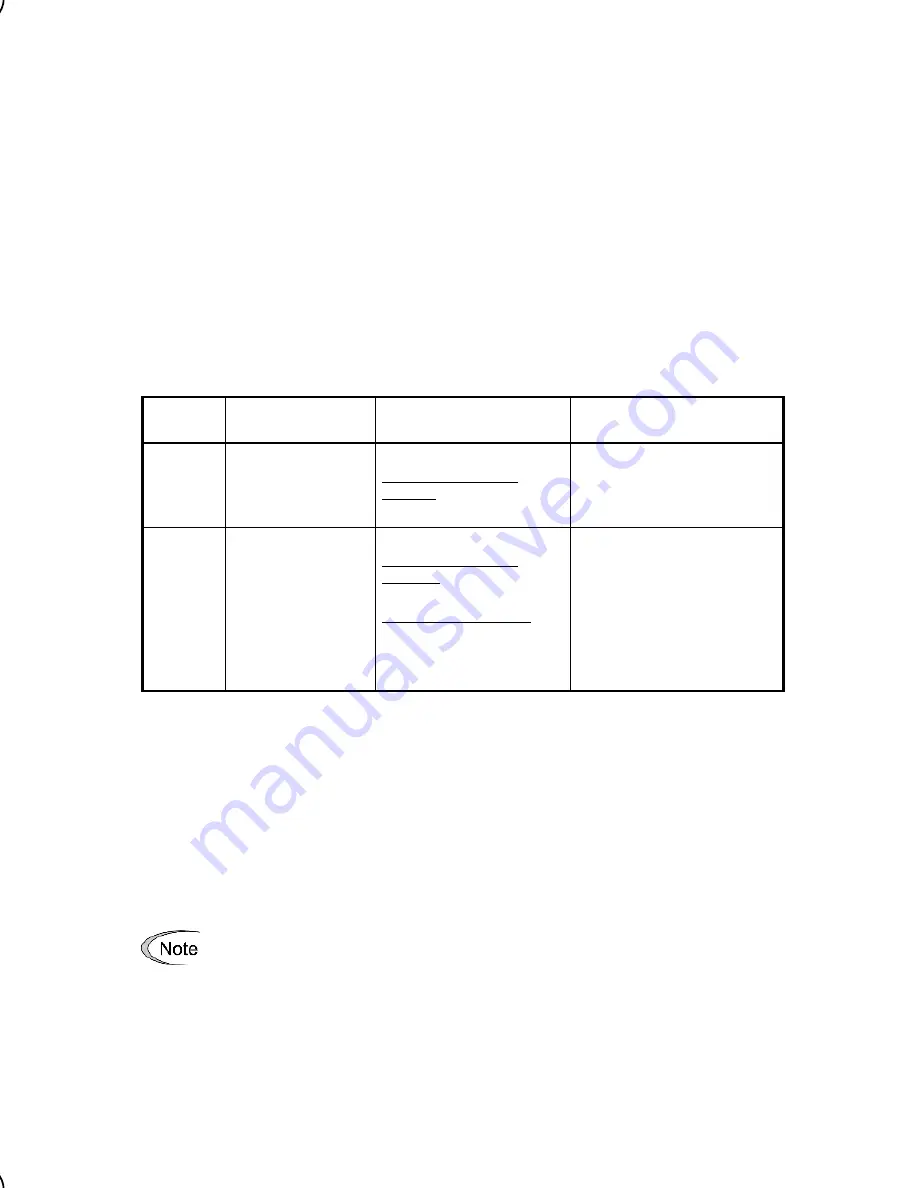

Data for

P04, A18

Motor parameters

subjected to tuning:

Tuning type

Selection condition

of tuning type

1

Primary resistance

(%R1) (P07, A21)

Leakage reactance

(%X) (P08, A22)

Tuning the %R1 and %X,

with the motor being

stopped.

The motor cannot be rotated

or 50% or more of the rated

load would be applied to the

motor if rotated.

2

Primary resistance

(%R1) (P07, A21)

Leakage reactance

(%X) (P08, A22)

No-load current

(P06, A20)

Rated slip frequency

(P12, A26)

Tuning the %R1 and %X,

with the motor being

stopped.

Tuning the no-load current,

with the motor running at

50% of the base frequency.

Even if the motor is rotated, it

is safe and no more than 50%

of the rated load would be

applied to the motor if rotated.

(Tuning with no load will

obtain the highest precision.)

Upon completion of the tuning, each motor parameter will be automatically saved into the

applicable function code.

3) Preparation of machine system

Perform appropriate preparations on the motor and its load, such as disengaging the

coupling and deactivating the safety device.

Switch to the motor 1 or motor 2, which the tuning is to be performed on.

Tuning results by P04 will be applied to P codes for the motor 1, and tuning results by A18

will be applied to A codes for the motor 2.

Assigning the

SWM2

signal ("Switch to motor 2")

to terminal [Y1] or [30A/B/C]

automatically switches the output status of

SWM2

depending on the motor

selected for tuning.