Section 4 Refrigeration

4-11

Verify Refrigerant Type In The System

Dedicated Equipment

R-134a must not be mixed with other types of

refrigerants. R-134a must be recovered in dedicated

and properly identified recovery bags and tanks.

It will be necessary to check with the manufacturer of

your recovery equipment to determine R-134a

compatibility. Some recovery equipment manufacturers

have changeover instructions for switching between

refrigerant types. Protect yourself and your equipment

by following all manufacturer guidelines.

Also, ensure that your refrigeration hoses are specified

for use with R-134a refrigerant. Research has shown

that compounds in standard refrigeration hoses may

enter sealed systems and ultimately restrict the cap tube

in an R-134a system.

R-134a Refrigeration Systems

The sealed refrigeration system will consist of the same

basic components being utilized in the R-12 systems.

There is a 10% to 15% discharge pressure increase

using R-134a, with a 5% to 10% decrease in suction

pressure when compared to the same product with an

R-12 system operating at 90°F (32°C) ambient

temperature conditions. Lower suction pressures result

from the lower density of R-134a refrigerant which

effects refrigerant flow rate. R-134a systems commonly

operate in a 1”-2” vacuum on the suction side.

Products using R-134a refrigerant will generally have a

longer capillary tube to maintain a similar flow rate and

some models will have a larger condenser to reduce the

discharge pressures and lower start-up sound

transmission.

Miscibility of R-134a and Ester Oil

A special synthetic oil known as Ester oil is used as a

lubricant in refrigeration systems operating on R-134a.

Ester oils are produced from alcohols and fatty acids and

are available in several different variants. Ester oils have

a pleasant aroma reminiscent of fruit.

Ester oils generally include various types of additives for

improving certain properties such as viscosity,

temperature sensitivity, etc. These additives are often

aggressive, and skin contact with Ester oils should

therefore be avoided.

One of the most important requirements made on a

refrigerant system is that the oil mix with the refrigerant.

Since mineral oil and ordinary synthetic oil DO NOT mix

with R-134a, Ester oil is used for lubrication. Ester oil

dissolves in R-134a.

Ester oil is broken down by chlorine and cannot be

used with R-12 (R-12 contains chlorine) or any other

compound containing chlorine. Therefore, R-134a

refrigeration systems have virtually no tolerance for

chlorine molecules from CFC refrigerants (R-134a is an

HFC and contains no chlorine).

During R-134a service, it is extremely important to

avoid using equipment that may contain residual

amounts of mineral oil, CFC’s or HCFC’s which could

enter and contaminate the sealed system.

CAUTION

R-134a and R-12 are completely incompatible. Before

starting any sealed system repair, it is extremely

important to check serial plate of product to verify the

type of refrigerant in the system.

CAUTION

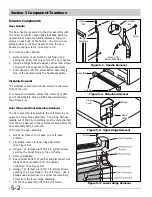

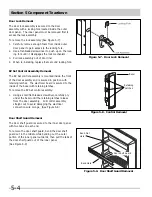

The following instructions are generalized to help the

technician understand the procedures of sealed

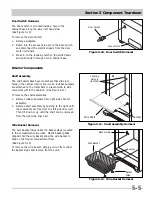

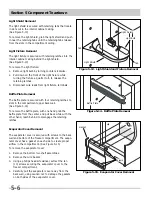

system repairs. See Section 5 Component Teardown

on the exact steps of accessing the components of

the refrigeration system.

NOTE

Summary of Contents for FFH17F8HW0

Page 2: ......

Page 14: ...Section 2 Installation Information 2 6 Notes ...

Page 18: ...Section 3 Electronic Control 3 4 Notes ...

Page 33: ...Section 4 Refrigeration 4 15 HFC 134a CFC 12 Pressure Temperature Chart ...

Page 36: ...Section 4 Refrigeration 4 18 Notes ...

Page 48: ...Section 5 Component Teardown 5 12 Notes ...

Page 53: ...Section 7 Wiring Diagram 7 1 ...