Section 4 Refrigeration

4-8

Equipment Needed for Evacuation &

Recharging:

•

Heated charging cylinder

•

Standard 3-port manifold gauge set:

- 4 charging hoses

- Tee fitting with valve core stem removed

(Robinair No. 40396)

- Hand shut-off valve (Robinair No.40380)

•

Two stage vacuum pump

•

Process tube adapter kit (Robinair No.12458)

•

Tubing cutter

•

Pinch-off tool capable of making leak proof seal

•

Complete brazing torch set

•

Small 3-corner file

•

Grit cloth or Scotch-Brite

•

45% silver solder and flux

•

Heat Gun

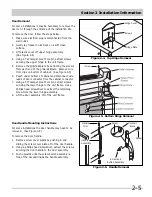

Installing Evacuation and Recharging

Equipment

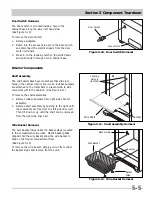

1. Disconnect freezer from electrical supply.

2. If compressor was replaced, install correct sized

process tube adapter on process tube.

If compressor was not replaced, cut process tube

with tubing cutter leaving as much tube as possible

and install correct size process tube adapter.

3. Install correct sized process tube adapter on

high-side process tube.

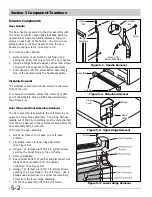

4. Attach refrigeration service gauge manifold to

system in following order:

• Low-side (compound gauge) hose to suction

side process tube adapter.

•

High-side (pressure gauge) hose to high-side

process tube adapter.

•

Center port manifold hose before hand shut-off

valve to charging cylinder.

•

Center port manifold hose after hand shut-off

valve to vacuum pump.

Check the serial plate for the correct refrigerant

type. It is extremely important to verify the type of

refrigerant in the system before starting any sealed

system repairs.

With the possible exception of the vacuum pump, all

service equipment that comes in contact with R-134a

during evacuation and recharging must be dedicated.

Accordingly, R-134a will require a dedicated charging

cylinder, manifold gauge set, process tube adapters,

and hoses. Any residual mineral oil on other tools

(tubing cutter, etc.) must be thoroughly cleaned off

before using on R-134a/Ester oil systems. It will be

necessary to check with the manufacturer of your

vacuum pump for refrigerant and oil compatibility

issues.

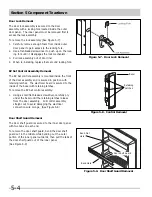

If you use a vacuum pump with mineral oil to evacuate

an R-134a system, it is ABSOLUTELY ESSENTIAL to

have a shut-off valve between the pump and your

manifold gauge set as shown on page 4-10. The hand

valve must be closed during all times when the

vacuum pump is not operating. This will prevent the

migration of mineral oil vapor into the R134a/Ester oil

system. If the vacuum pump should stop during

evacuation for any reason, the hand pump shut-off

valve must be closed immediately.

Insure that your refrigeration hoses are specified for

use with R-134a refrigerant. Research has shown that

compounds in standard refrigeration hoses may enter

sealed systems and ultimately restrict the cap tube in

an R-134a system.

CAUTION

Summary of Contents for FFH17F8HW0

Page 2: ......

Page 14: ...Section 2 Installation Information 2 6 Notes ...

Page 18: ...Section 3 Electronic Control 3 4 Notes ...

Page 33: ...Section 4 Refrigeration 4 15 HFC 134a CFC 12 Pressure Temperature Chart ...

Page 36: ...Section 4 Refrigeration 4 18 Notes ...

Page 48: ...Section 5 Component Teardown 5 12 Notes ...

Page 53: ...Section 7 Wiring Diagram 7 1 ...