耗材安装提示

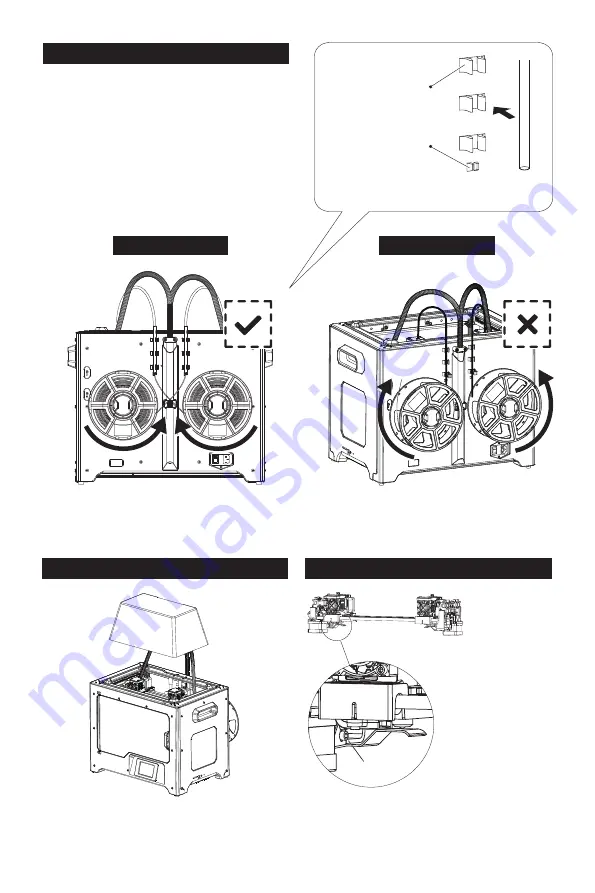

安装耗材时请注意耗材丝盘轴的安装方向。

如下图所示,请保证耗材从内测出丝。

耗材及导丝管安装完毕后,将耗材穿过导丝

管导入左喷头进丝孔中。当您准备将耗材插

入喷头前,请按下喷头一侧的进丝压板。

将导丝管卡入机身背部的导丝管固定卡扣中。

注意:请注意将导丝管延伸到丝盘轴内部,以防止丝料脱开被缠绕在丝盘外部。

1.

2.

安装正确:内侧出丝

安装错误:外侧出丝

导丝管固定卡扣

导丝管限位卡座

20

当打印 ABS 材料时建议安装此顶盖;

当打印 PLA 材料时无需安装此顶盖。

安装防溢丝板,使用2颗螺丝固定。

3.安装顶盖

4.防溢丝板安装

M3x8

可手动调节防溢丝板

与喷嘴的距离,请确

保安装后喷嘴可触碰

到防溢丝板表面。经

过一段时间的打印,

防溢丝板表面出现划

痕为正常现象。

Summary of Contents for Creator Pro 2

Page 15: ...Creator Pro 2 1 2 1 2 3 4 14...

Page 16: ...6 5 X 7 8 10 9 15...

Page 18: ...3D USB SD 3D CREATORPRO2 PRO2 17...

Page 19: ...1 M2 5 4 M3 1 2 3 4 18...

Page 20: ...2 1 2 3 19...

Page 21: ...1 2 20 ABS PLA 2 3 4 M3x8...

Page 22: ...1 2 3 75 220 21...

Page 23: ...1 2 3 22...

Page 24: ...XYZ 1 2 Z Creator Pro 2 Z 50 3 Z Z Z Z Z 0 08 Z Z Z Z Z X Y Z 23...