1.

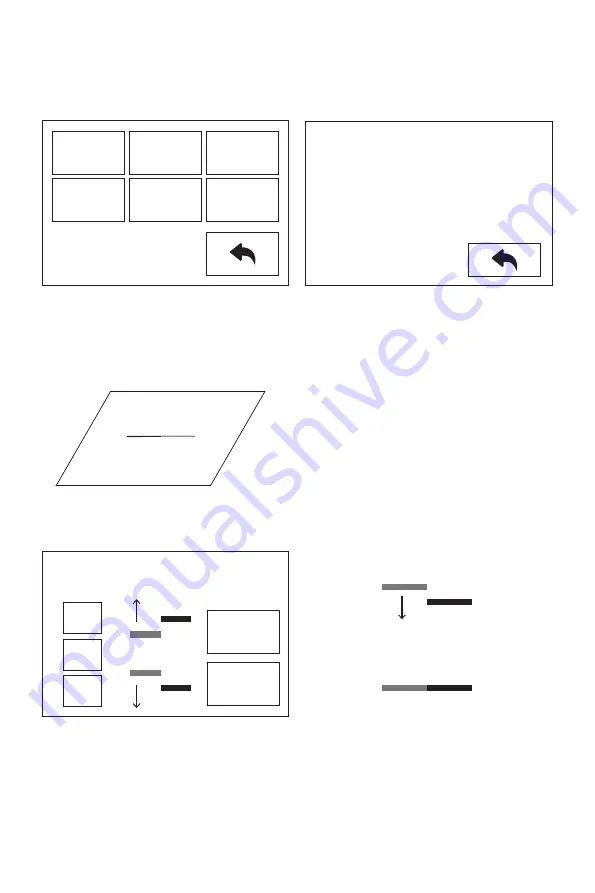

Tap [Setting]-[Y Calibration], or continue the Y-axis calibration after the X-axis calibra-

tion is completed. After the machine initialization movement is completed, the nozzle

and the platform will be heated. At this time, please ensure that the filament has been

inserted into the extruder.

Y-axis calibration: Used to adjust the consistency of the two extruders in the Y-axis

direction to prevent misalignment during printing.

Y Axis Calibration

Y Calibration

L: 152/200

R: 164/200

B: 45/50

2. After heating, left and right extruders print a line one by one.

3.

According to the actual printed lines, click Y-, Y + to adjust the bias of the extruders and

remove the printed lines; tap the verify button, the left and right extruders will print the

lines again to see if the lines coincide, if they coincide, it means that the Y-axis

calibration is completed, if they are inconsistent, continue to adjust, until it coincides.

Please tap Y-,Y+ to adjust and verify make

sure the lines are aligned.

OK

Verify

Y+

0.00

Y-

Y-

R

L

Y+

R

L

Y-

L

R

L

R

X

Calibration

Y

Calibration

Z

Calibration

Expert

Mode

Language

FactoryReset

12

Summary of Contents for Creator Pro 2

Page 15: ...Creator Pro 2 1 2 1 2 3 4 14...

Page 16: ...6 5 X 7 8 10 9 15...

Page 18: ...3D USB SD 3D CREATORPRO2 PRO2 17...

Page 19: ...1 M2 5 4 M3 1 2 3 4 18...

Page 20: ...2 1 2 3 19...

Page 21: ...1 2 20 ABS PLA 2 3 4 M3x8...

Page 22: ...1 2 3 75 220 21...

Page 23: ...1 2 3 22...

Page 24: ...XYZ 1 2 Z Creator Pro 2 Z 50 3 Z Z Z Z Z 0 08 Z Z Z Z Z X Y Z 23...