EXTRA BRUSH HEAD PRESSURE

This machine is capable of increasing the pressure exerted upon the brushes during the work cycle. This can be done in the following manner:

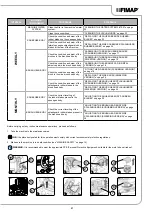

1.

Check to make sure that the brush head body is in contact with the floor. If this is not the case, adjust the brush head control lever (4) on the

steering column (

Fig.4

).

2. Engage the “EXTRA-PRESSURE ACTIVATION/DEACTIVATION” lever (5) underneath the steering wheel (

Fig.5

).

3. Press the drive pedal (2) (

Fig.2

), and the machine will begin to work.

N.B.:

Once the lever (5) has been engaged, the red indicator light (6) on the steering column will turn on to indicate that the extra-

pressure function has been enabled (

Fig. 6

).

BUZZER

The machine is equipped with an acoustic signalling device. If an acoustic signal needs to be emitted, simply press the button (7) on the control

panel (

Fig.7

).

WORKING HEADLIGHTS (OPTIONAL)

Upon request, the machine can be equipped with front and rear working lights. These lights can be turned on by setting the main switch to “I”, by

turning the key (8) a quarter turn to the right (

Fig.8

).

EMERGENCY BUTTON

If any problems are encountered during work operations, press the emergency button (9) on the carter that covers the electrical system (

Fig.9

).

CAUTION:

This command interrupts the electrical circuit between the batteries and the machine system.

N.B.:

After having stopped and resolved the problem, the work operations can be resumed by doing the following:

1. Bring the main switch to the "0" position by turning the key (8) a quarter turn anti-clockwise (

Fig.10

).

2. Move the mushroom-head emergency button (9) forwards (

Fig.11

).

3. Bring the main switch to the "I" position, turning the key (8) a quarter turn clockwise (

Fig.8

).

BRAKING CONTROL

The machine has an encoder to help braking and also a mechanical brake. If the machine is moving and the accelerator pedal (2) is released,

the machine brakes, decelerating gently, until it stops the encoder. Only when the encoder has stopped is the electric brake engaged. If the

machine is moving and the brake pedal (10) (

Fig.12

) is pressed, the machine brakes according to the braking force of the mechanical system.

Only when the encoder has stopped is the electric brake engaged.

ALARM SCREEN

If there is an error, the writing AL is shown on the control display followed by a number (

Fig.13

), this stays visible until the error is resolved.

When an error occurs, do as follows:

1. Stop the machine immediately.

2.

If the error persists, switch off the machine, wait for at least ten seconds and switch on the machine.

3. If the error persists contact the nearest service centre.

List of alarms:

NUMBER

TYPE

DESCRIPTION

AL_1

General

Memory error

AL_2

General

Key fault

AL_3

General

Undervoltage

AL_4

General

Overvoltage

AL_5

General

Batt. connection

AL_6

General

Dashboard communication

AL_7

General

FFM communication

AL_8

General

Internal communication 1

AL_9

General

Internal communication 2

AL_10

General

Enter tag

AL_11

General

Invalid tag

AL_12

General

Update in progress…

AL_13

General

Switch-off

AL_14

General

Recovery tank full

NUMBER

TYPE

DESCRIPTION

AL_15

General

Brake fluid Reserve

AL_41

Function

Overtemperature

AL_42

Function

Power board damaged

AL_43

Function

Main fuse faulty

AL_44

Function

Main contactor faulty

AL_45

Function

Main contactor faulty - CC

AL_46

Function

Overcurrent - brush outputs 1-2-3

AL_47

Function

Overcurrent - vacuum cleaner outputs 1-2

AL_48

Function

Overcurrent - water pump outputs

AL_49

Function

Amperometric - brush output 1

AL_50

Function

Amperometric - brush output 2

AL_51

Function

Amperometric - brush output 3

AL_52

Function

Amperometric - vacuum cleaner output 1

AL_53

Function

Amperometric - vacuum cleaner output 2

24