1.3 General safety instructions

1.3.3 Working in presence of aluminium dust

Warning!

Risk of explosion from high concentrations of aluminium

dust. Risk of injury from breathing in fine particulate.

• When carrying out any work that creates fine particles of

dust, wear a fine dust mask, safety goggles and protective

gloves.

• Any grinding work must be carried out with explosion-

protected air extraction systems; do not blow off dust

deposits with compressed air.

• Clean the work area and the extraction system regularly.

• To prevent a dust explosion, all extraction systems must

be earthed and suitable powder extinguishers must be

provided.

• Any vehicle parts in the repair area which may be damaged

by dust should be removed from the area or covered with

fire-resistant covers.

Copyright ©

2010

1.3.4 Handling batteries

Warning!

Risk of explosion and fire from flying sparks during

grinding and welding work. Risk of damage to vehicle

components and other vehicles from flying sparks.

• Before carrying out any welding work, always remove both

battery terminal clamps and cover the battery terminals.

• Remove the vehicle battery before carrying out any work

that may produce sparks in the vicinity of the battery itself.

• Disconnect the battery earth strap when carrying out any

vehicle body repair work and when working on the airbag

system.

Summary of Contents for 458 Italia

Page 1: ......

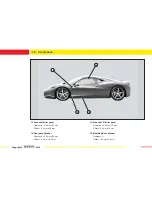

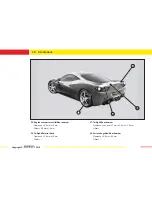

Page 24: ...1 7 Car Bench vehicle bench Copyright 2010 ...

Page 25: ...1 7 Car Bench vehicle bench Copyright 2010 ...

Page 26: ...1 7 Car Bench vehicle bench Copyright 2010 ...

Page 27: ...1 7 Car Bench vehicle bench Copyright 2010 ...

Page 28: ...1 7 Car Bench vehicle bench Copyright 2010 ...

Page 29: ...1 7 Car Bench vehicle bench Copyright 2010 ...

Page 30: ...1 7 Car Bench vehicle bench Copyright 2010 ...

Page 31: ...1 7 Car Bench vehicle bench Copyright 2010 ...

Page 522: ...Hook 95977564 AS 107564 for lifting the gearbox Page 5 of 5 Specific tooling and equipment ...

Page 586: ...In preparation Page 6 of 6 Engine overhaul Disassembly ...

Page 620: ...Perform the Fuel tank tightness test cycle Page 4 of 4 Fuel level sensor ...

Page 967: ...Refit the wheels D2 01 Page 10 of 10 Stabiliser bars Tie rods ...

Page 1127: ...Refit the wheels D2 01 Page 8 of 8 Wheelhouse ...

Page 1167: ...Prise out and remove the plug 4 Undo the nut 5 Undo the nut 6 Page 32 of 37 Doors ...

Page 1242: ...In the LOWEST position two movements are possible Page 8 of 12 Seats ...

Page 1243: ...In the INTERMEDIATE LOW position three movements are possible Page 9 of 12 Seats ...

Page 1244: ...In the INTERMEDIATE HIGH position three movements are possible Page 10 of 12 Seats ...

Page 1549: ...Reconnect the battery F2 01 Page 5 of 5 Starter motor ...

Page 1721: ...Charge the air conditioning system F5 12 Page 5 of 5 Condenser ...

Page 1740: ...Refit Page 13 of 13 A C unit ...

Page 1764: ...FD0001 Fuel supply distribution 0 99999 Page 10 of 56 PDF ...

Page 1765: ...FD0001 Fuel supply distribution 0 99999 Page 11 of 56 PDF ...

Page 1773: ...FD0001 Fuel supply distribution 0 99999 Page 19 of 56 PDF ...

Page 1774: ...FD0001 Fuel supply distribution 0 99999 Page 20 of 56 PDF ...

Page 1781: ...FD0001 Fuel supply distribution 0 99999 Page 27 of 56 PDF ...

Page 1782: ...FD0001 Fuel supply distribution 0 99999 Page 28 of 56 PDF ...

Page 1789: ...FD0001 Fuel supply distribution 0 99999 Page 35 of 56 PDF ...

Page 1790: ...FD0001 Fuel supply distribution 0 99999 Page 36 of 56 PDF ...

Page 1797: ...FD0001 Fuel supply distribution 0 99999 Page 43 of 56 PDF ...

Page 1798: ...FD0001 Fuel supply distribution 0 99999 Page 44 of 56 PDF ...

Page 1803: ...FD0001 Fuel supply distribution 0 99999 Page 49 of 56 PDF ...

Page 1804: ...FD0001 Fuel supply distribution 0 99999 Page 50 of 56 PDF ...

Page 1809: ...FD0001 Fuel supply distribution 0 99999 Page 55 of 56 PDF ...