12

Removing or Installing the Right Side Sliding

Fence (Fig. 19)

1. Unlock the fence cam-locking lever, and slide the

sliding fence to the right.

2. Remove the hex screw (3) by a using a 3 mm hex

key.

3. Lift up on the sliding fence to remove it from the

saw.

4. Replace the sliding fence and thread the hex screw

to lock the sliding fence when not making right bevel cuts.

Compound Cut (Fig. 20)

1. Extending the fence by sliding it out to the required

location or remove the right sliding fence if necessary.

2. Set the desired bevel angle using the bevel lock

handle (2).

3. Set the desired mitre angle and lock into position.

See “MITRE CUT”.

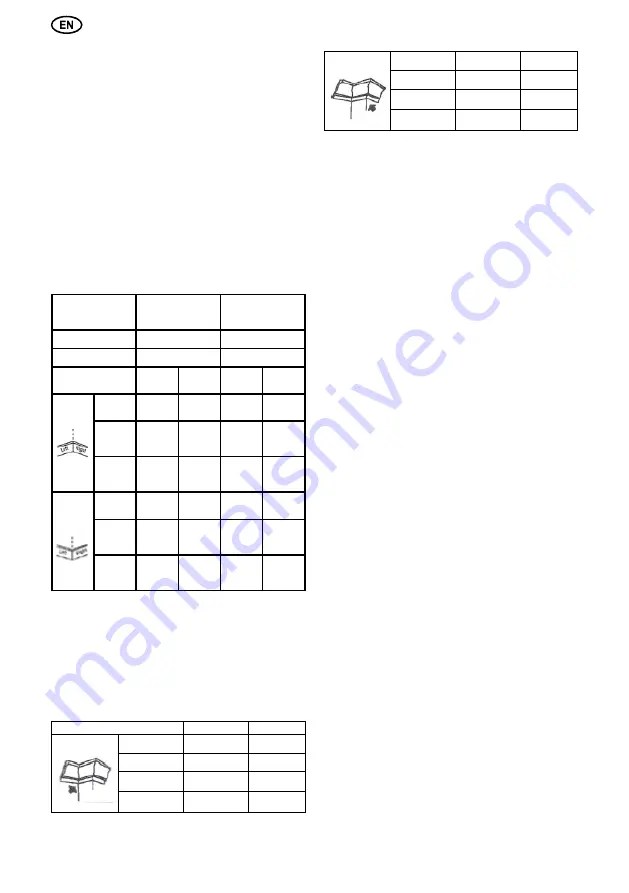

Base Moulding Cut (Fig. 21)

1. Base moulding can be cut vertical against fence or

flat on the table. Follow the table below for reference.

SETTINGS

Vertical Position

(Back of moulding is

against the fence)

Horizontal Position

(Back of moulding is

flat on the table)

Extension Fence

Close to the blade

Far from the blade

Bevel Angle

0°

45°

Moulding Position

Left side

Right

side

Left side

Right

side

Inside

Corner

Mitre

Angle

Left at

45°

Right at

45°

0°

0°

Moulding

position

Bottom

against

table

Bottom

against

fence

Top

against

fence

Bottom

against

fence

Finished

side

Keep left

side of

cut

Keep

right side

of cut

Keep left

side of

cut

Keep left

side of

cut

Outside

Corner

Mitre

Angle

Right at

45°

Left at

45°

0°

0°

Moulding

position

Bottom

against

table

Bottom

against

table

Bottom

against

table

Top

against

fence

Finished

side

Keep left

side of

cut

Keep

right side

of cut

Keep

right side

of cut

Keep

right side

of cut

Crown Moulding Cut (Fig. 22)

1. Crown moulding can only be cut flat on the table for

this mitre saw.

2. This mitre saw has special mitre stops of 31.6°

left and right and a bevel stop of 33.9° for a special crown

moulding, i.e. 52° between the back of the moulding and

the top flat surface that fits against the ceiling; 38° between

the back of the moulding and the bottom flat surface that

fits against the wall. Refer to the following table for this

crown moulding cut.

SETTINGS

Left Side

Right Side

Inside Corner

Mitre Angle

31.6° Right

31.6° Left

Bevel Angle

33.9°

33.9°

Moulding

Position

top against

fence

bottom against

fence

Finished Side

Keep left

side of cut

Keep left

side of cut

Outside Corner

Mitre Angle

31.6° Left

31.6° Right

Bevel Angle

33.9°

33.9°

Moulding

Position

bottom against

fence

top against

fence

Finished Side

Keep right side

of cut

Keep right side

of cut

NOTE:

1. These special stops can not be used with 45° crown

moulding.

2. Since most rooms do not have angles of exactly

90°, fine tune is needed and always take a test cut to

confirm the correct angles.

Pullover Cut (Fig. 23)

WARNING!

- Never pull the cutting head assembly and spinning

blade toward you during the cut. The blade may try to climb

up on the top of the workpiece, causing the cutting head

assembly and spinning blade to kick back.

- Never lower spinning saw blade down before pulling

the cutting head to the front of the saw.

1. Unlock the carriage lock handle (1) and allow the

cutting head assembly to move freely.

2. Set both the desired bevel angle and/or the mitre

angle and lock into position.

3. If bevel cutting, set both the left and right sliding

fences (2) to their proper location.

4. Use a hold down clamp to secure the workpiece.

5. Grasp the saw handle (3) and pull the carriage (4)

forward until the centre of the saw blade is over the front of

the workpiece (5).

6. Pull the trigger (6) to turn the saw on.

7. When the saw reaches full speed, push the saw

handle down, slowly, cutting through the leading edge of

the workpiece.

8. Slowly move the saw handle toward the fence,

completing the cut.

9. Release the trigger and allow the blade to stop

spinning before allowing the cutting head to raise.

Setting Cutting Depth (Fig. 24)

The depth of cut can be preset for even and repetitive

shallow cuts.

1. Adjust the cutting head down until the teeth of the

blade are at the desired depth of cut.

2. While holding the upper arm in position, turn the

stop knob (1) until it touches the stop plate (2).

3. Recheck the blade depth by moving the cutting

head front to back through the full motion of a typical cut

along the control arm.

The Arbour Laser Guide

Your tool is equipped with our latest innovation, the

Arbour Laser Guide, a battery powered device using

Class 1M laser beams. The laser beams will enable you

to preview the mitre blade path on the workpiece to be cut

before you begin your operation.

DANGER!

Laser is activated when blade is rotating.

Do not stare into beam or view directly with optical

instruments. Do not remove the warning label affixed

to the blade guard. Avoid direct eye contact with light

source.

NOTE:

The red laser line will appear as a dotted line

when the motor is activated and the blade assembly is in

the uppermost position. This broken line will assist you in

aligning the mark on your workpiece with the cutting path

of the saw blade. As you lower the blade assembly, the

Summary of Contents for SRF305/1800

Page 2: ...2 26 Mod SRF305 1800E Fig 3 1 2 3 Fig 6 1 Fig 6...

Page 3: ...3 4...

Page 5: ...5...

Page 52: ...52 1 b 2 b d f 3 b d f g 4 b d...

Page 62: ...62 40 80 FELISATTI FELISATTI...

Page 63: ......