- 11 -

Remove residues of the old gasket or sealant before reinstallation, grind with a grindstone if the

contact surface has any damage.

The ends of rubber hoses (for fuel, vacuum, or coolant) should be pushed as far as they can go to

their connections so that there is enough room below the enlarged ends for tightening the clamps.

Connector

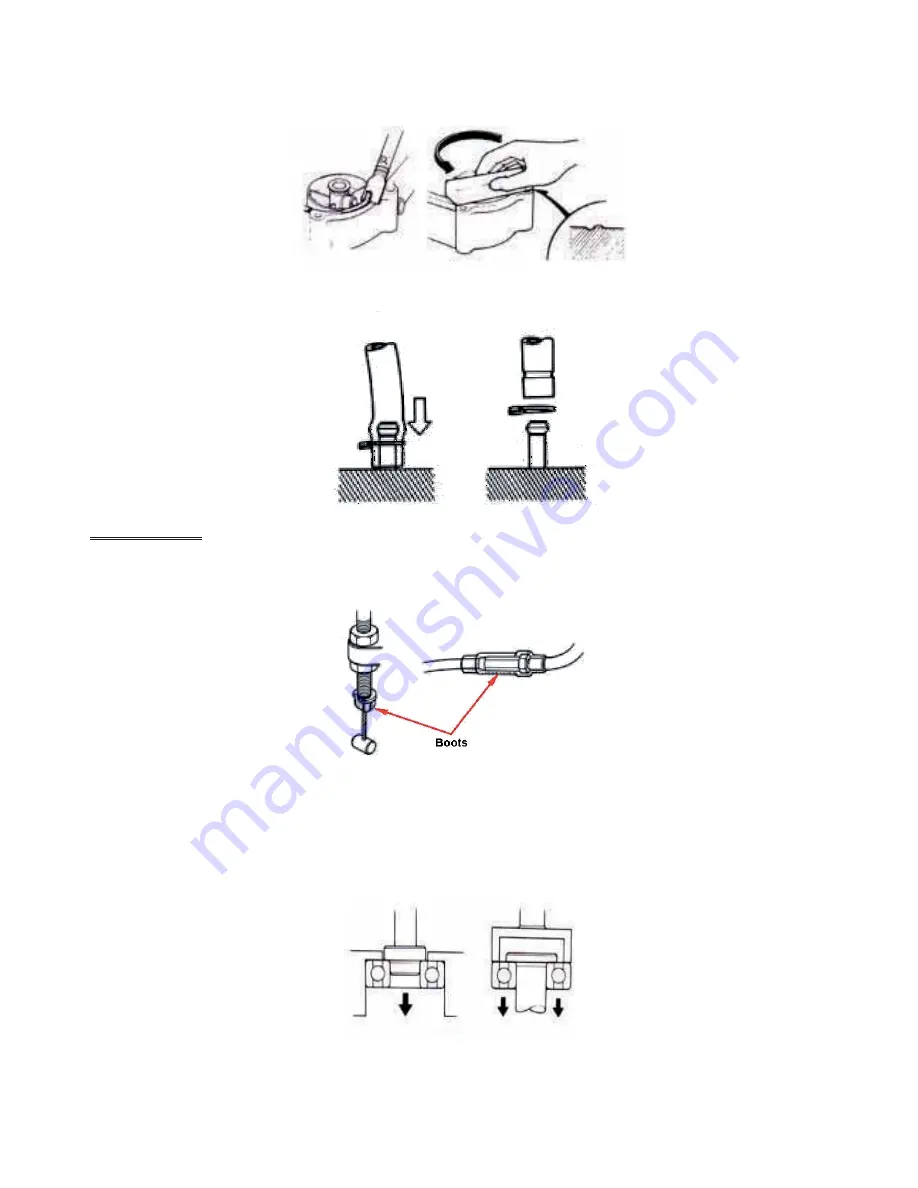

Rubber and plastic boots should be properly reinstalled to the original correct positions as

designed.

The tool should be pressed against two (inner and outer) bearing races when removing a ball

bearing. Damage may result if the tool is pressed against only one race (either inner race or outer

race). In this case, the bearing should be replaced. To avoid damaging the bearing, use equal force

on both races.

(Both of these examples can result in bearing damage)

Summary of Contents for Patriot 430

Page 1: ...SERVICE MANUAL PATRIOT 430...

Page 4: ...3 SERIAL NUMBER Frame number Engine number Home page Contents...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...26...

Page 28: ...27 7 Lubrication Points...

Page 71: ...70 Muffler mounting bolt 12 N m Tighten the muffler bolts specified torque 29 N m...

Page 139: ...L CASE R CASE...

Page 148: ...Apply Loctite 510 Flange sealant to the mating surface of the left crankcase L CASE R CASE...

Page 161: ......

Page 162: ......

Page 235: ...1 Electrical Diagram 18 1...