18

3.3 Cutting blade installation & indexing

EUROBOOR B60(S) comes pre-assembled with 10 cutting blades. Operation of the machine wears the

cutting blades out, and they need to be checked before every use. Work solely with sharp and

undamaged cutting blades, as per EUROBOOR recommendation. There are multiple ways to ensure

maximum performance of the cutting blades:

-

Indexing the cutting blades by rotating the blades 90 degrees in the tool holder, until all

clean and sharp edges have been used and worn. This must be done in the exact same way

for all 10 blades at the same time

-

Swapping the inner and outer blades if only the overlapping corners show signs of wear, as

to make maximum use of the unused edge corners

-

Replacing the cutting blades if they are completely worn out or no longer suitable for the

operating task at hand. All 10 blades need to be replaced at the same time

Following steps cover all above mentioned handlings.

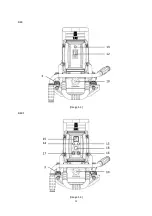

3.3.1 Disassembly milling head cover

To access the milling head, it is advised to disassemble the milling head cover (including guide plates

and rollers) from the machine. The following steps need to be taken:

1.

Loosen the depth adjustment lock handle completely

2.

Pull out the threaded rod (which has the beveling depth indicator attached)

3.

Gently pull off the complete milling head cover

[image 2-1]

Reassembly of the milling head cover is done in reverse order. Be careful to reposition all

components completely and without damaging them.

Summary of Contents for B60

Page 2: ...2 ...

Page 4: ...4 ...

Page 11: ...11 B60 B60S B60S shown image 1 1 image 1 2 ...

Page 12: ...12 B60 image 1 3 B60S image 1 4 ...

Page 20: ...20 image 2 3 ...

Page 39: ...39 8 Exploded view spare part list 8 1 Exploded views B60 ...

Page 40: ...40 B60 CONTINUED ...

Page 41: ...41 B60S ...

Page 42: ...42 B60S continued ...

Page 45: ...45 8 3 Wiring diagrams B60 ...

Page 46: ...46 B60S ...

Page 48: ...48 ...