5.8.

Marking pen, retention pin, marking / Retention unit assy.

1)

Replacement of marking/ retention unit Assy.

-

Removal

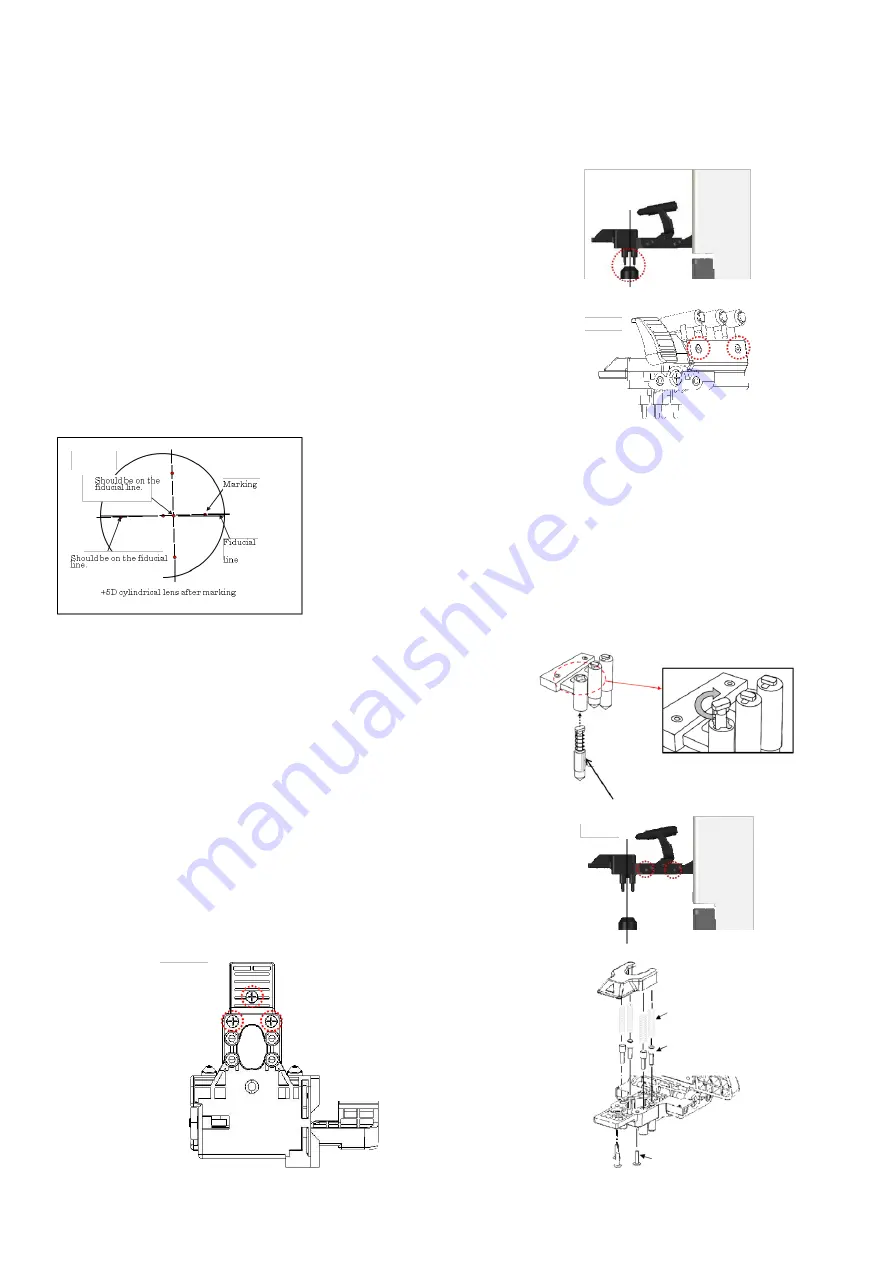

Unscrew 2 screws (cross recessed binding screw M3×10 black) fixing the marking/ retention unit Assy.

-

Installation

Install the marking/retention unit Assy. so that the lens

retention pin is positioned roughly in the center of the light

receiving unit.: Fig. 4

Check the marking position by taking a measurement of

cylinder lens of the maintenance lens set.

[Fig.4]

Adjustment when marking is not on fiducial line

Loosen 2 screws (hexagonal socket cap bolt M2×6 black)

fixing the marking unit, adjust it so as that the marking is

on the cylindrical lens in the maintenance lens set and fix

the marking unit. :Fig. 5

[Fig.5]

<Confirmation procedure>

Perform alignment by placing +5D cylindrical

lens with contacting with the lens plate in the

direction of AX 180. At this time, adjust the

marking unit so as that the marking is on the

fiducial line.

Then, perform alignment by placing +5D

cylindrical lens with contacting

with the lens plate in the direction of AX 90

without erasing the marking. At this time, the

marking in the middle should be on the fiducial

line.

2)

Replacement of Marking Pen

Press the marking pen as shown below and rotate it 90

degrees. Insert the new pen in the original position.

3)

Replacement of Lens Retention Pin

Unscrew 2 screws (cross-recessed bind screw M3×10

black) fixing the marking/ retention unit Assy. :Fig. 1

Unscrew 3 screws (cross-recessed bind head tapping

screw 2×8 black) fixing the lens retention unit. Replace

the pins by disassembling the lens retention unit. :Fig. 2

and 3

[Fig.1]

[Fig.2]

[Fig.3]

Marking pen

Cross recessed bind head

tapping screw 2x8 black

Lens retention pin

Compression spring

Summary of Contents for ALM 700

Page 1: ...Maintenance manual Auto Lensmeter ALM700 V1 10 2016...

Page 36: ......