22

Beeper

Whe

n

a

n

error occ

u

rs wh

i

le “Beep No

ti

f

i

ca

ti

o

n

Se

tting

a

t

a

n

Error”

i

s e

n

abled,

t

he beeper

performs “So

un

d

t

he beeper o

n

a

n

error” show

n

in

t

he below

t

able. The beeper co

ntinu

es

t

o

beep

unti

l all

t

he ca

u

ses of error are removed.

Whe

n

"Se

tting

s For Paper Ha

n

dl

ing

Af

t

er Pr

int

" - "No

ti

f

i

ca

ti

o

n

"

i

s e

n

abled,

t

he pr

int

er performs

“Beeper so

un

d whe

n

t

he pr

int

er

i

s

n

o

t

in

a

n

error s

t

a

t

e” show

n

in

t

he below

t

able.

❏

Freq

u

e

n

cy:

F

i

xed

t

o approx

i

ma

t

ely 2.5 kHz

❏

Vol

u

me co

nt

rol:

2 levels o

n

t

he hardware

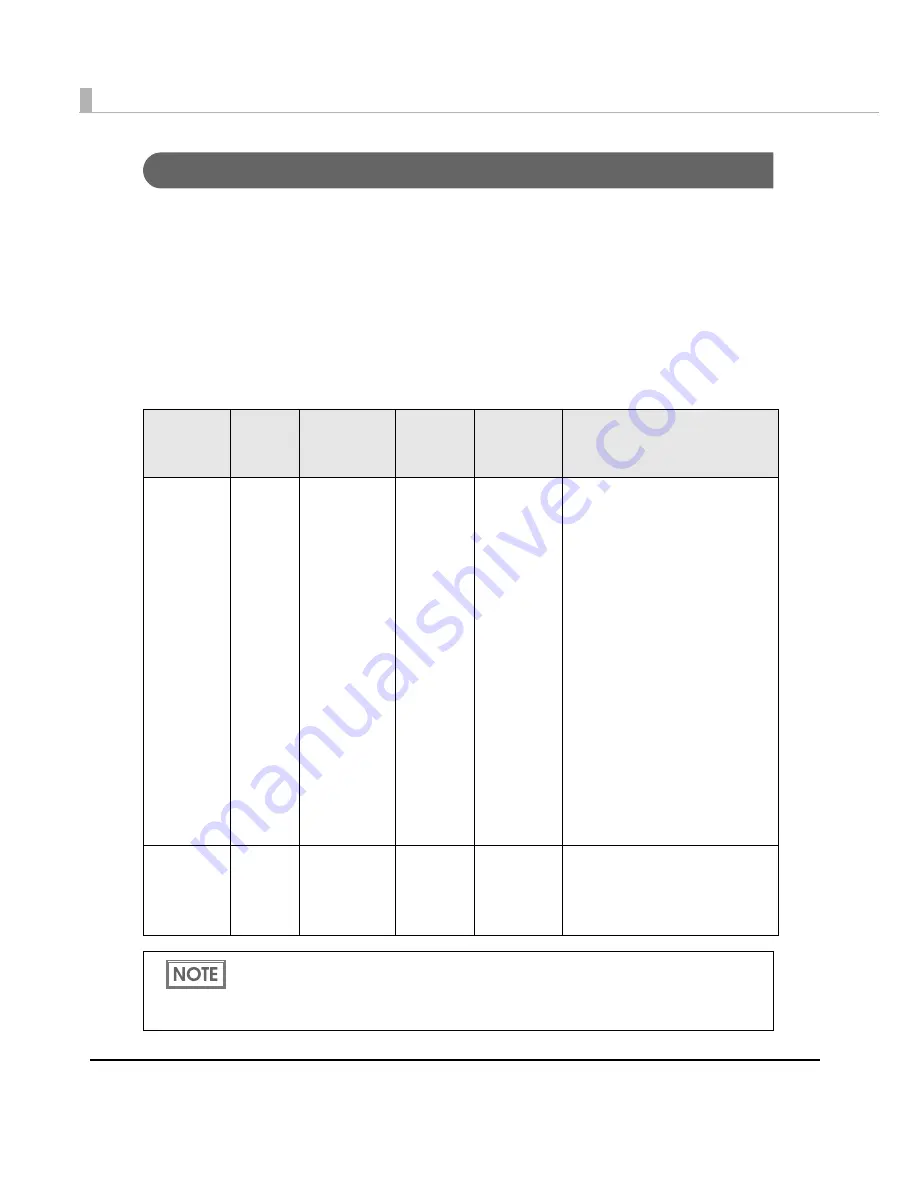

Sounding

period

Silent

period

Number of

the pattern

repeated

Overall

time

Number of

times

repeated

Printer event

500ms

300ms

3

5 seconds

Until the

error factor

is removed.

Sound the beeper on an error

Service required

Printer error

Roll paper cover open

Ink cartridge cover open

Replace ink cartridge

No ink cartridge

Ink cartridge read error

Maintenance box cover open

Replace maintenance box

No maintenance box

Maintenance box read error

Media form error

Media size error

Paper jam error

Paper removal error

Paper out error

300ms

-

None

-

1

Beeper sound when the printer

is not in an error state

Every page

The final page only

The volume can be set using the DIP switch. See

"Setting the DIP Switches" on page

48.

When the paper is in “Paper out” status, which is without printing data, the beeper does

not sound.

Summary of Contents for TM-C3500 Series

Page 41: ...Chapter 2 Setup 41 2 4 Close the roll paper cover ...

Page 52: ...52 TM C3500 PrinterSetting TM C3500 PrinterSetting is used to change various printer settings ...

Page 158: ...158 4 Error Recovery to LCD Display appears ...

Page 182: ...182 ...

Page 188: ...188 Barcode Font List Barcode Font Replacement List ...