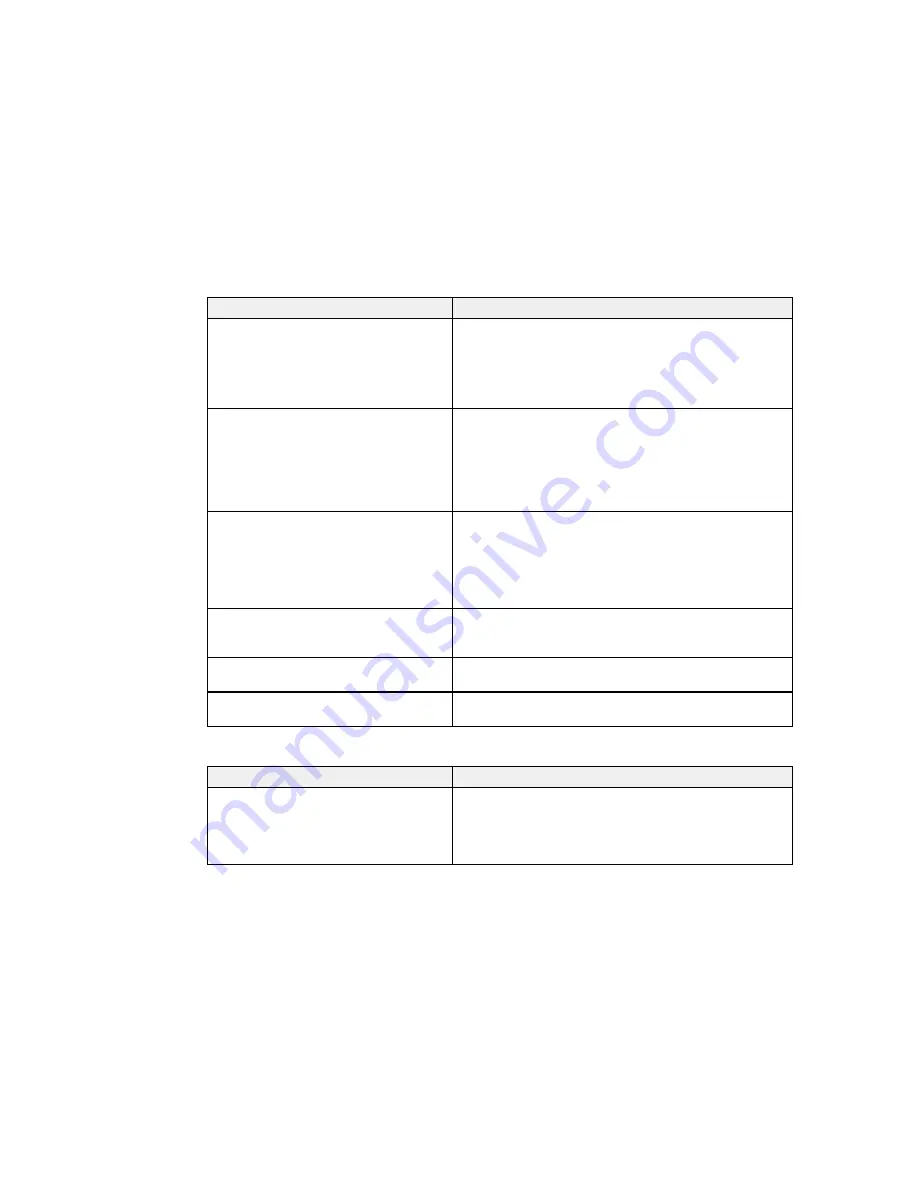

Options

Description

Tension Measurement

Selects how often tension is measured and automatically

adjusted:

Periodically:

recommended for most media.

Every page:

provides more precise tensioning (but slower

printing).

Feeding Tension

Select

Auto

for most media.

When you select

Manual

, you can set a value from

0

to

40

.

If media creases, set the value higher than

Lv32

. If banding

appears, set the value lower than

Lv32

.

When

Media Size Check

is off, select

Manual

and set the

value based on the media width.

Take-up Tension

Select

Auto

for most media.

When you select

Manual

, you can set a value from

1

to

9

.

If media wrinkles, banding appears, or ink sticks to the

back of the take-up roll, set the value lower than

Lv7

. If

thick media cannot be wound correctly, set the value higher

than

Lv7

.

Feed Speed

Select

Lv2

for most media. Select

Lv1

for thin media if it is

creased, torn, stuck together, or if horizontal banding

appears.

Prevent Sticking

Select

On

only if the media sticks to the platen when the

printer is turned on or when printing starts.

Restore Settings

Select

Yes

to return all settings for the selected media to

their default values.

RIP Settings

options

Options

Description

Platen Gap

Select

2.0

for most media. Select

1.5

if print quality is

unsatisfactory. Select

2.5

only if printouts are scratched or

smudged. Choosing a larger gap than necessary can

cause ink stains inside the printer, reduced print quality, or

shorter product life.

81

Summary of Contents for SureColor F9200

Page 1: ...Epson SureColor F9200 User s Guide ...

Page 2: ......

Page 7: ...Epson SureColor F9200 User s Guide Welcome to the Epson SureColor F9200 User s Guide 7 ...

Page 11: ...Slider Chip Holder Parts 1 Slider 2 Ink inlet cover 3 Chip unit LAN Port Parts 11 ...

Page 26: ...Printable side in 6 Place your media on the roll supports temporarily 26 ...

Page 29: ...9 Tighten the roll holder fixing screw until it no longer turns 29 ...

Page 38: ...23 Open the front cover 24 Lower the media loading lever to hold the media in place 38 ...

Page 55: ...1 Move the Auto switch to the off position 55 ...

Page 60: ...9 Tighten the left roll core holder locking screw to secure the roll core holder in place 60 ...

Page 77: ...7 Lower the media roll onto the roll support Parent topic Using the Auto Take up Reel 77 ...

Page 98: ...2 Grasp the loop at the top of the ink inlet cap and slowly remove the ink inlet cap 98 ...

Page 108: ...8 Open the ink inlet cover 108 ...

Page 110: ...Rest the stirring stick on the tab at the edge of the tank as shown 110 ...

Page 111: ...111 ...

Page 112: ...10 Cut or tear off the ink pack spout seal 112 ...

Page 139: ...1 Raise the ink splash guard on the waste ink bottle 139 ...

Page 143: ...3 Grasp the wiper cleaner and lift it out of your product as shown 143 ...

Page 149: ...5 Align the white line on a new media holding plate with the edge of the platen 149 ...

Page 174: ...7 Attach the left bracket over the loosened screws as shown and slide it to the left 174 ...

Page 177: ...10 Perform a parallel adjustment Parent topic Moving or Transporting the Product 177 ...

Page 194: ...6 Place the tabs over the screws at the front of the product and attach them as shown 194 ...

Page 215: ...19 Use the small hexagon wrench to loosen the two screws 215 ...