o

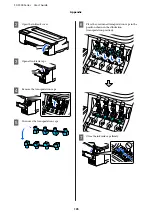

Is there a gap between both edges of the roll

paper and the flanges?

Confirm that the spindle flanges are right up against

both edges of the roll paper, with no gaps. If there are

any gaps, then the paper is fed at an angle, and this

may result in wrinkling.

U

“Loading Roll Paper” on page 26

o

Has Media Adjust been carried out?

Confirm that paper type settings that match the paper

being used, and perform Media Adjust.

U

“Setting Loaded Paper” on page 35

U

“Optimizing Paper Settings (Media Adjust)” on

o

Is the roll paper tension weak?

If wrinkles occur on the roll paper, increase the paper

tension settings. In the Roll paper information area -

Advanced Media Setting

-

Back Tension

, select

High

or

Extra High

.

The reverse side of the printed paper

is soiled.

o

Is ink dry on the printed surface?

Depending on the printing density and paper type,

the ink may take a while to dry. Do not stack the paper

until the printed surface is dry.

Additionally, setting the drying time on the printer in

Roll Paper

-

Advanced Media Setting

-

Drying Time

-

Drying Time per Page

to a longer time will stop

post-print processing (ejection, cutting), waiting for

the paper to dry naturally.

U

Blurred text, lines, and images

o

Is the Media Type setting correct?

Confirm that the paper type selected with the printer

matches the paper being used, and that the printer

driver Media Type settings are

Use Printer Settings

.

The amount of ink to be fired is controlled according

to the media type. If the settings do not match the

paper loaded, too much ink may be fired.

U

“Setting Loaded Paper” on page 35

o

Is the Color Density setting appropriate?

On the printer driver Advanced screen, click

Paper

Configuration

, and decrease the ink density. The

printer may be printing with too much ink for some

paper. We recommend that black and color densities

be decreased similarly.

o

Are you printing on tracing paper?

If too much ink is discharged, on the printer driver

Advanced screen, click

Paper Configuration

, and

decrease the ink density. Alternatively, changing the

Paper Type

to

Tracing Paper <LowDuty>

may result

in an improvement.

Feeding or ejecting problems

Unable to feed or eject paper.

o

Is the paper loaded in the correct position?

See the following for the correct paper loading

positions.

U

“Loading Roll Paper” on page 26

U

“Loading paper into the auto sheet feeder” on

U

“Loading Cut Sheet(1 sheet)” on page 34

o

Is the paper loaded in the correct direction?

Load cut sheets vertically. If they are not loaded in the

correct direction, the paper may not be recognized

and an error may occur.

U

“Loading paper into the auto sheet feeder” on

U

“Loading Cut Sheet(1 sheet)” on page 34

o

Is the paper wrinkled or creased?

Do not use old paper or paper with creases in it.

Always use new paper.

o

Is the paper damp?

Do not use paper that is damp. Also, Epson special

media should be left in the bag until you intend to use

it. If it is left out for a long time, the paper curls up and

gets damp so that it does not feed properly.

SC-F500 Series User's Guide

Problem Solver

125