G

Select the items to adjust according to the color of

the media being used, and then press

Start

.

Pressing the

x

button starts printing the

adjustment pattern. When printing the pattern is

complete, the adjustment value entry screen is

displayed. Continue to the next procedure.

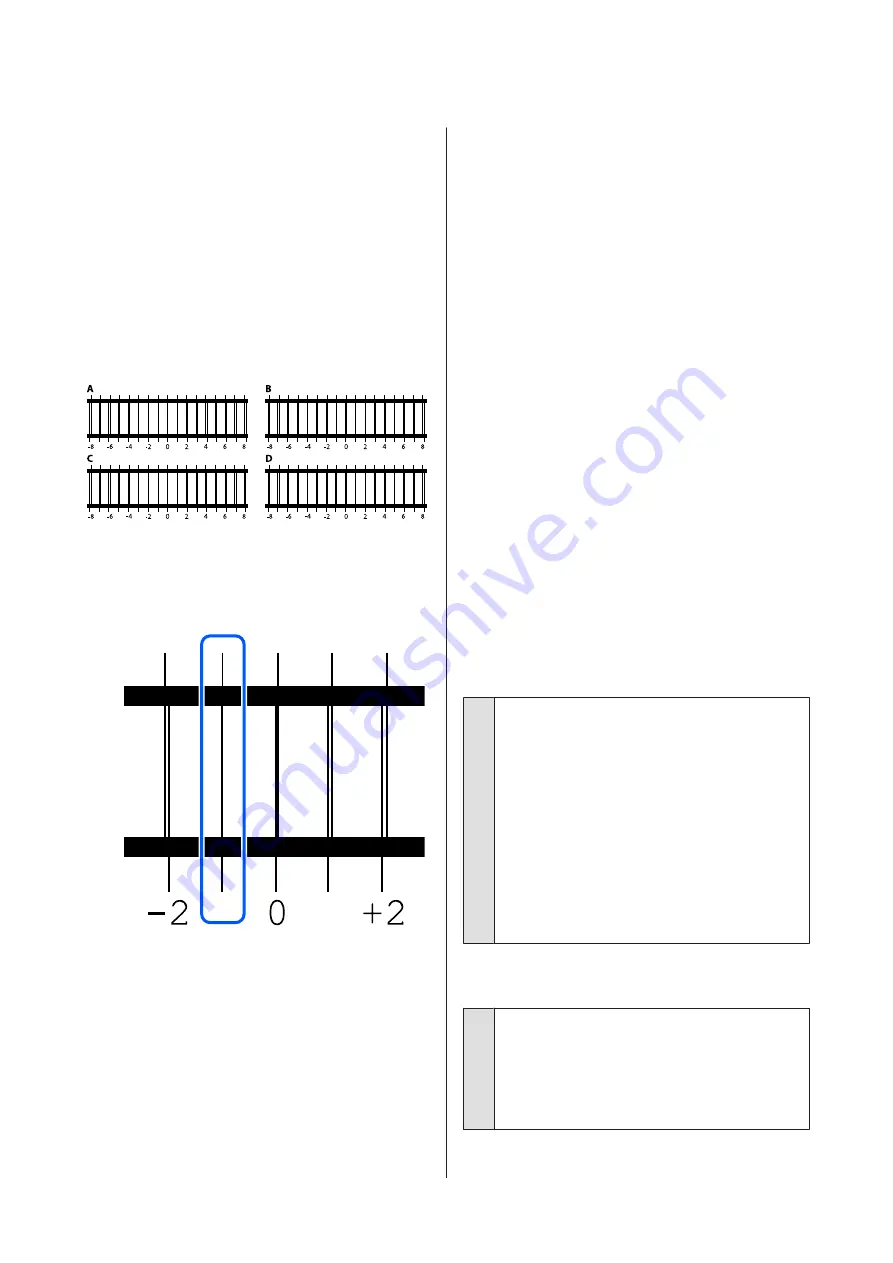

H

Check the printed adjustment pattern.

When

Light Media

is selected, 2 blocks (#1 to #2)

of black patterns are printed. When

Dark Media

is selected, 2 blocks at a time (#1 to #4) of black

patterns are printed.

Check the 4 patterns A to D in each block, and

select from -8 to +8, where the line appears

thinnest (lines overlap) in the pattern.

Select "-1" in the following illustration.

Check the patterns in all the blocks, and then go

to the next step.

I

Input the adjustment values.

When executing Standard:

Input the adjustment values in order A to D that

you selected in step 8 for all of the blocks #1 to #4

(#1 to #2 for

Light Media

). Inputting all of the

adjustment values and pressing

OK

opens a

screen for confirming the adjustment values.

Check the adjustment results and press

OK

to

reflect the adjustment results to the media

settings.

When executing Micro Adjust:

You can input setting values from +10 to -10. We

recommend first setting both adjustment values

to +1 and -1 and printing, and then doing further

adjustments based on the value that improved

image quality.

When image quality is not improved after

adjustments

❏

When executing

Standard

:

Next, execute

Micro Adjust

.

❏

When executing

Micro Adjust

:

When using

Auto

for the

Platen Gap

, try setting the

Head Height

to

Narrow

. However, when

Narrow

is set, the surface of the media is more likely to

contact the print head. Load the media carefully so

there are no wrinkles on its surface.

If changing the

Head Height

to

Narrow

does not

improve image quality, try setting the

Platen Gap

to

Manual

.

U

“Media Settings menu” on page 116

Alternatively, try the following measures.

o

Try uni-directional printing.

If the problem is not resolved by doing the above

measures, try setting

Uni-Direction (Low Speed)

for

Print Direction

in Garment Creator for SC-F3000

Series, the software for the printer. To do repeat

printing or to print a job from a USB memory stick that

has already been set to

Bi-Direction (High Speed)

,

set

Head Move Direction

to

Uni-Directional

on the

preview screen.

U

“When reprinting (repeat printing) the same job”

U

“Printing from a USB Memory” on page 73

The printed surface is soiled

o

Is the suction cap clean?

The printed surface may be soiled from dripping ink if

lumps of ink or lint are stuck around the suction cap.

Clean the suction cap.

U

“Cleaning the Suction Cap” on page 85

SC-F3000 Series User's Guide

Problem Solver

129