Envision One cDLM® User Manual

TS-MAM-EnvisionOneCDLMUserManual-V5.0-FN-EN , 2021-12-15

Page 71 of 73

Annex 1: Troubleshooting

IMPORTANT

For each task, the safety warnings contained in this instruction manual must be observed.

In case of any problem not listed in this troubleshooting chapter, contact your customer support.

Do not try to fix the problem without consulting the customer support first as it will void your

warranty!

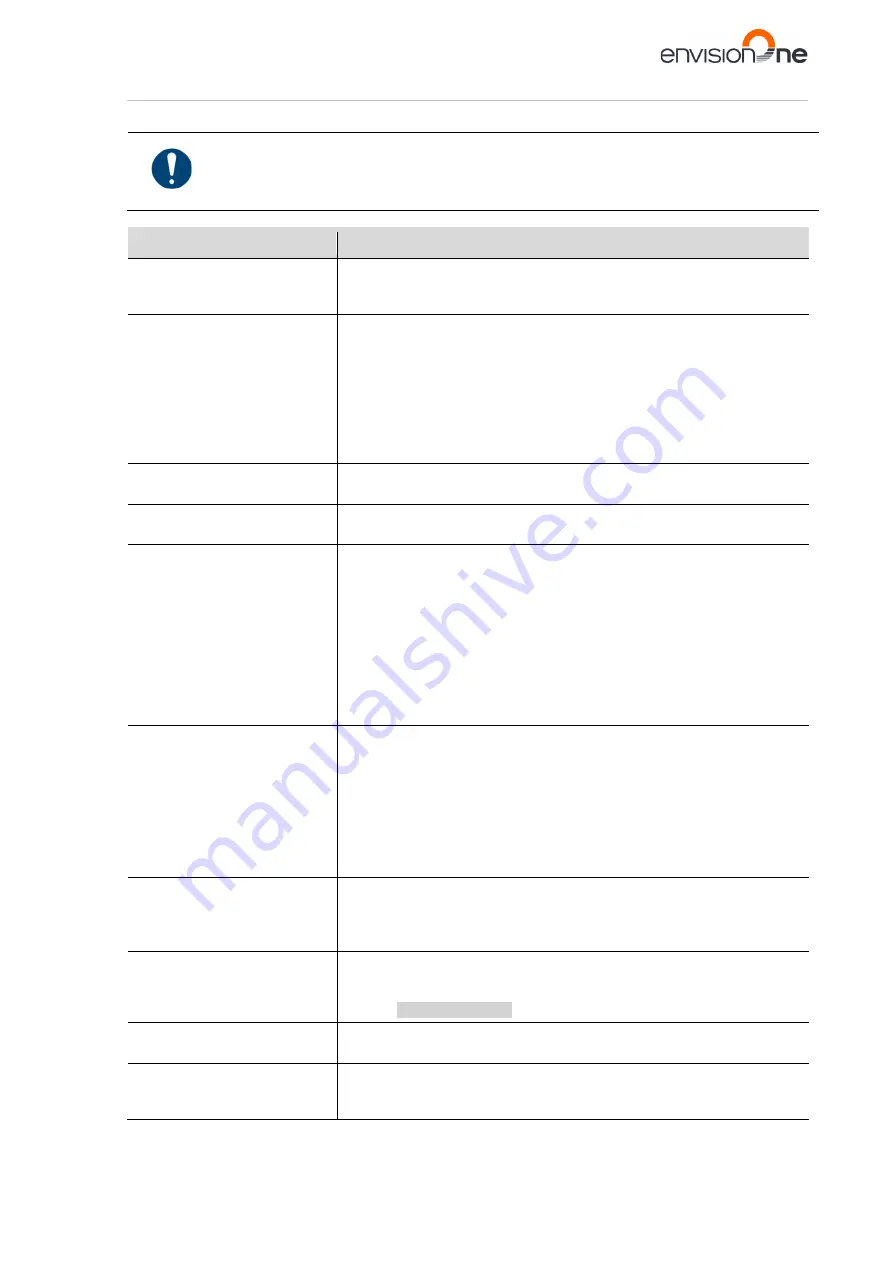

Problem

Remedy

My Z slide isn’t moving when I

tap the relevant buttons in the

Control Software.

1. Unplug both the power supply and the USB from the back of the printer.

2. Wait for 10 seconds and reconnect.

3. If the problem still persists, call technical support.

The built model fell off the build

platform or nothing substantial

was built.

1. Filter your material using a paint strainer to ensure there is no debris left

from the failed job in it.

2. Wipe out and check your material tray to ensure it is still in good

condition.

3. If your material tray or material is over 6 months, it may be time to order

new ones.

4. If this is not the case and you still cannot get a good job after straining

or using fresh material, you may have an issue with your LED or the

homing position of the build platform. Call technical support.

Time out Reached

message

appears on the screen.

The projector cannot be initialized. In this case, restart the printer by shutting

it down and then powering it on again.

Error 4252

This can be caused by the wrong material usage.

Contact Service & Support and provide the information on the material used.

Sporadic blurring on part.

It is caused by contaminated material from alcohol or some other chemical.

1. Pour the old material in separate container. Do not pour it back into new

or unused material container.

2. Clean out the material tray completely with dry soft paper towels only,

don’t use any chemicals.

3. Clean the corners of the material tray with dry Q tips.

4. Replace with new material and rebuild parts.

To avoid future contamination:

•

Do not place any chemical near material tray or resin.

Do not post clean the part near the material tray, and do not clean the build

platform with any chemicals but only dry paper towels.

Partial build failure

This could be several things or a combination of the following:

•

Damaged, scratches, hole or worn material tray will cause a build

failure.

•

Weak supports. A weak or improperly placed support will cause a part

feature not to build. Add additional supports to the failed area.

•

Boolean operation is not correct, errors in file. A small feature is not

completely attached to the main body of the part. In Magics or your CAD

program check to ensure there is no gap, all small features are

completely attached and the part is a one single entity.

Build falling off the build platform

•

Damaged, scratches, hole or worn material tray will cause this build

failure.

•

Dirty optics: clean the glass between the material tray and projector.

•

Call customer service.

Tag reader/DLP board/projector

connection lost

When the connection error appears:

1. Reboot the printer.

2. Contact Service & Support.

3.

Error message:

Invalid Auto

Homing parameter

Auto Homing parameter has the invalid value in Buildstyle. Contact Service

& Support.

Error message:

Job is too high.

Please regenerate job in

Envision One RP.

The job is too high for the printer`s Z-axis. Regenerate the number of layers

and/ or layer depth) of the job in Envision One RP.