34

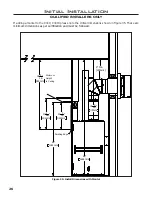

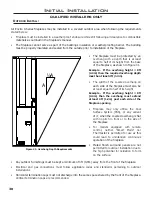

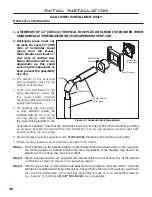

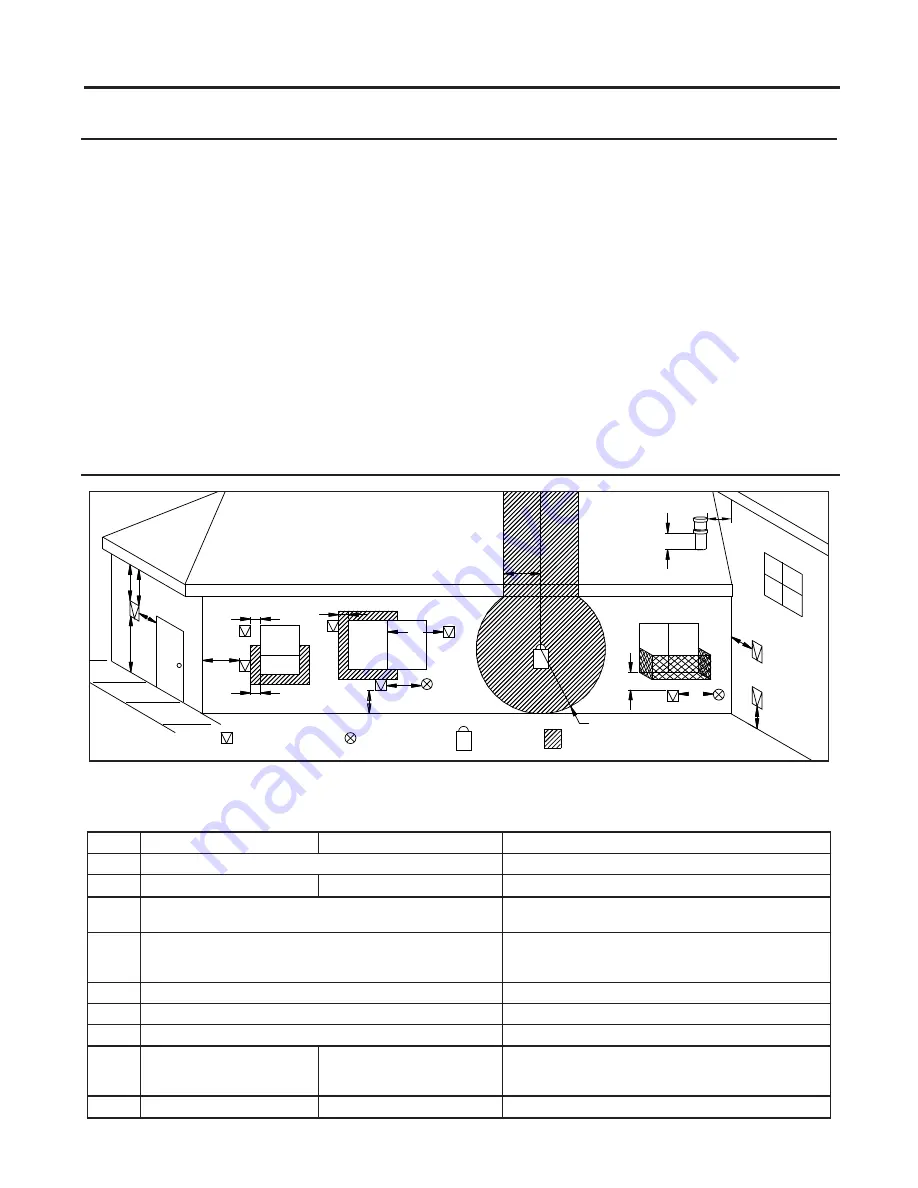

Figure 46:

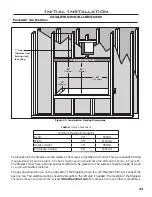

Vent Termination Restrictions, refer to Table 2

Initial Installation

QUALIFIED INSTALLERS ONLY

A

A

D E

L

B

C

F

B

B

B

J

M

K

G

H

I

Openable

Fixed

Closed

Openable

Fixed

Closed

Termination Cap

Air Supply Inlet

Gas Meter

G

G

Restriction Zone

(Termination not allowed)

N

O

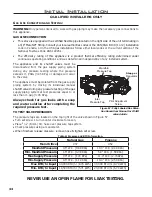

Letter

Canadian Installation

1

US Installation

2

Description

A

12 in (30 cm)

Clearance above grade, verandah, porch, deck, or balcony.

B

12 in (30 cm)

9 in (23 cm)

Clearance from window or door that may be opened.

C

12 in (30 cm)*

Clearance from permanently closed window (to prevent

condensation).

D

24 in (60 cm)*

Vertical clearance to ventilated soffit located above the

terminal, within a horizontal distance of 2 ft (60 cm) from

center line of terminal.

E

18 in (45 cm)*

Clearance to unventilated soffit.

F

12 in (30 cm)*

Clearance to outside corner.

G

12 in (30 cm)*

Clearance to inside corner.

H

3 ft (91 cm) within a height of

15 ft (4.5 m) above the meter/

regulator assembly

3 ft (91 cm) within a height of

15 ft (4.5 m) above the meter/

regulator assembly*

Clearance to each side of center line extended above me-

ter/regulator assembly.

I

3 ft (91 cm)

3 ft (91 cm)*

Radial clearance around service regulator vent outlet.

Table 3: Vent Termination Clearances

V

ent

t

eRmination

R

estRictions

:

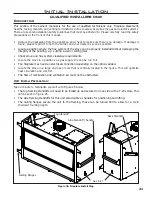

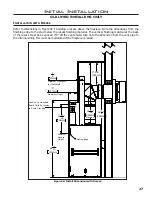

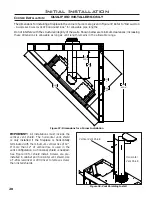

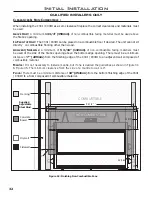

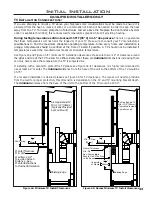

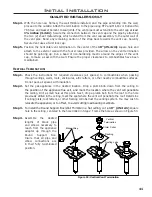

WARNING: This appliance has been designed to draw room air and discharge heated air

from the openings around the finishing edge. Blocking or modifying these openings in

any way can create hazardous situations. Only Approved Direct Vent may be used for

installation of the C34I / C34ID�

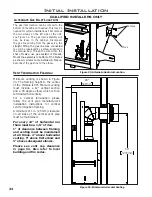

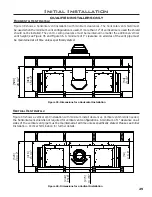

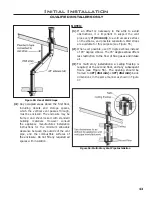

The minimum vent installation for the C34I / C34ID must include a 12” vertical section and 90°

elbow before being horizontally vented. Maximum Vertical venting is 40’ (12.2 m).

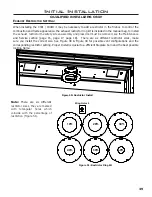

This

model is vented with co-axial 5” exhaust, 8” intake aluminum or stainless steel approved rigid vent

leading into a vertical or horizontal termination cap. The flue collar of this model will fit inside of a

standard 5”x 8” vent and must be either correctly interlocked or fastened, with three screws directly to

the vent collar.

Check periodically that the vents are unrestricted. Also ensure that all direct vent pipes have been

properly sealed and installed after routine inspection or cleaning. The air intake and exhaust pipes must

be installed in the correct locations on the top of the C34I / C34ID.

D

iRect

V

ent

:

Summary of Contents for C34I

Page 55: ...55 Parts Diagram 1 2 3 5 4 10 8 7 9 12 13 14 6 11 15 ...

Page 57: ...57 Notes ...

Page 58: ...58 Notes ...