24

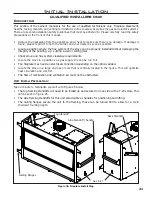

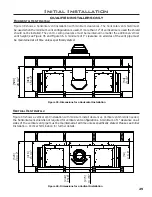

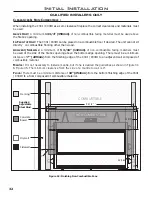

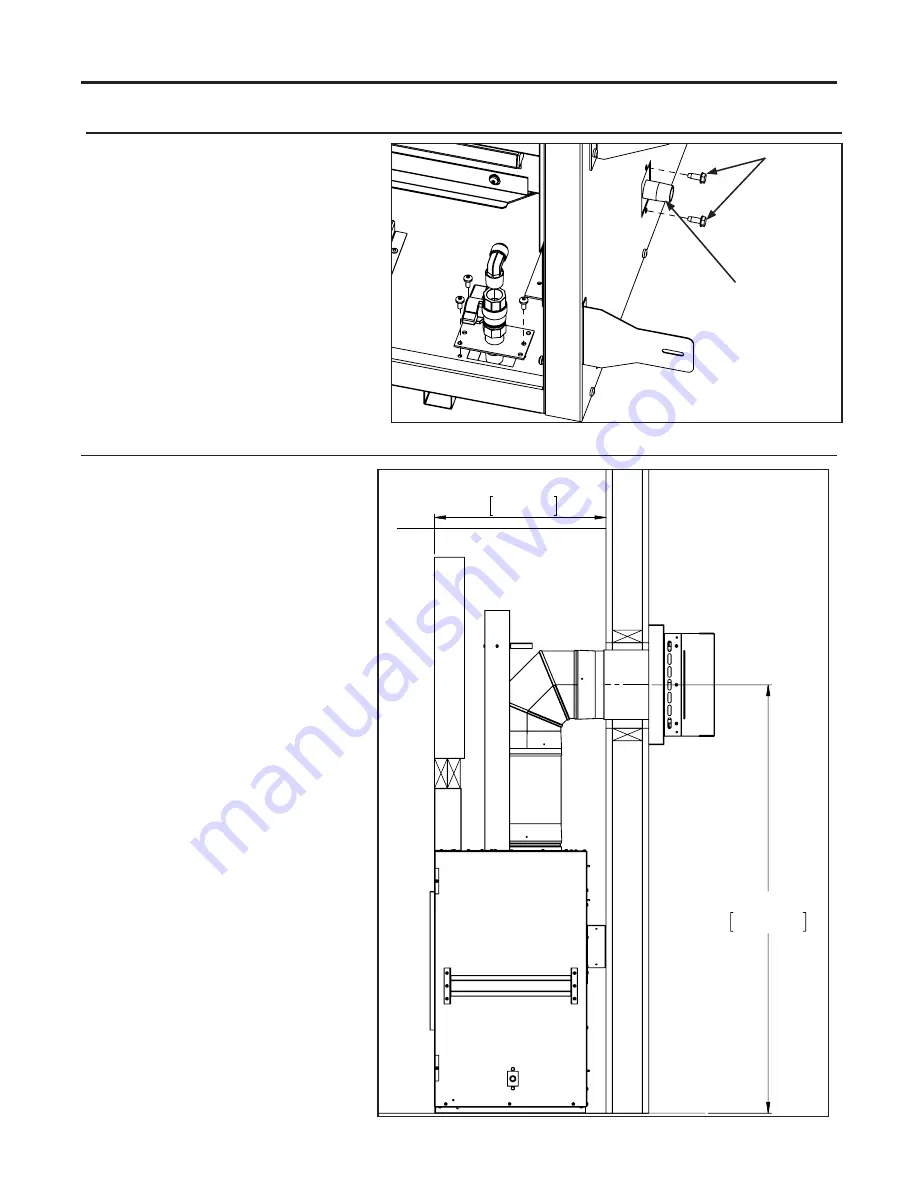

20"

509mm

50"

1272mm

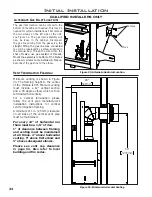

Initial Installation

QUALIFIED INSTALLERS ONLY

V

ent

t

eRmination

F

Raming

:

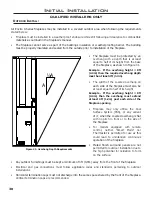

Minimum venting is shown in Figure

33. The framing height to the center

of the thimble is 50”. Minmum venting

must include a 12” vertical section

and a 90 degree elbow which is then

terminated horizontally.

For a vertical termination please

follow the vent pipe manufacturer’s

installation instructions for vertical

vent termination framing.

A minimum of 1 in. (25 mm) clearance

on all sides of the vertical vent pipe

must be maintained.

For every 12” of horizontal run

there must be a 1/4” of rise�

1” of clearance between framing

and venting must be maintained

at all times� 2” above horizontal

venting. 9” above first elbow and

3” above subsequent elbows.

Please see vent cap clearance

in page 34. Also refer to local

building and fire codes.

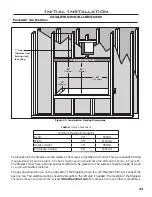

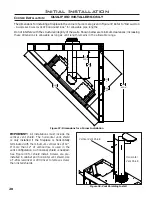

Figure 32:

Alternate Gas Inlet Location

a

LteRnate

g

as

i

nLet

L

ocation

:

The gas inlet location can be moved to the

bottom of the cabinet if needed. This may be

needed for certain installations. First remove

the two screws on the left side of the unit,

see Figure 32. The gas inlet assembly will

now be loose in the cabinet. Disconnect

the gas line coming from the gas valve, the

straight fitting the gas line was connected

too will be reaplaced by a elbow supplied in

the manual bag. Thread the elbow into the

shut off valve, use gas sealant of threads.

Mount the assembly to bottom of the firebox

as shown, screws come installed in firebox.

Reconnect the gas line to the elbow.

Remove

Figure 33: Minimum Horizontal Venting

Move

Summary of Contents for C34I

Page 55: ...55 Parts Diagram 1 2 3 5 4 10 8 7 9 12 13 14 6 11 15 ...

Page 57: ...57 Notes ...

Page 58: ...58 Notes ...