A200 SMIF POD

5

User Manual | Entegris, Inc.

Procedures

Shell Assembly

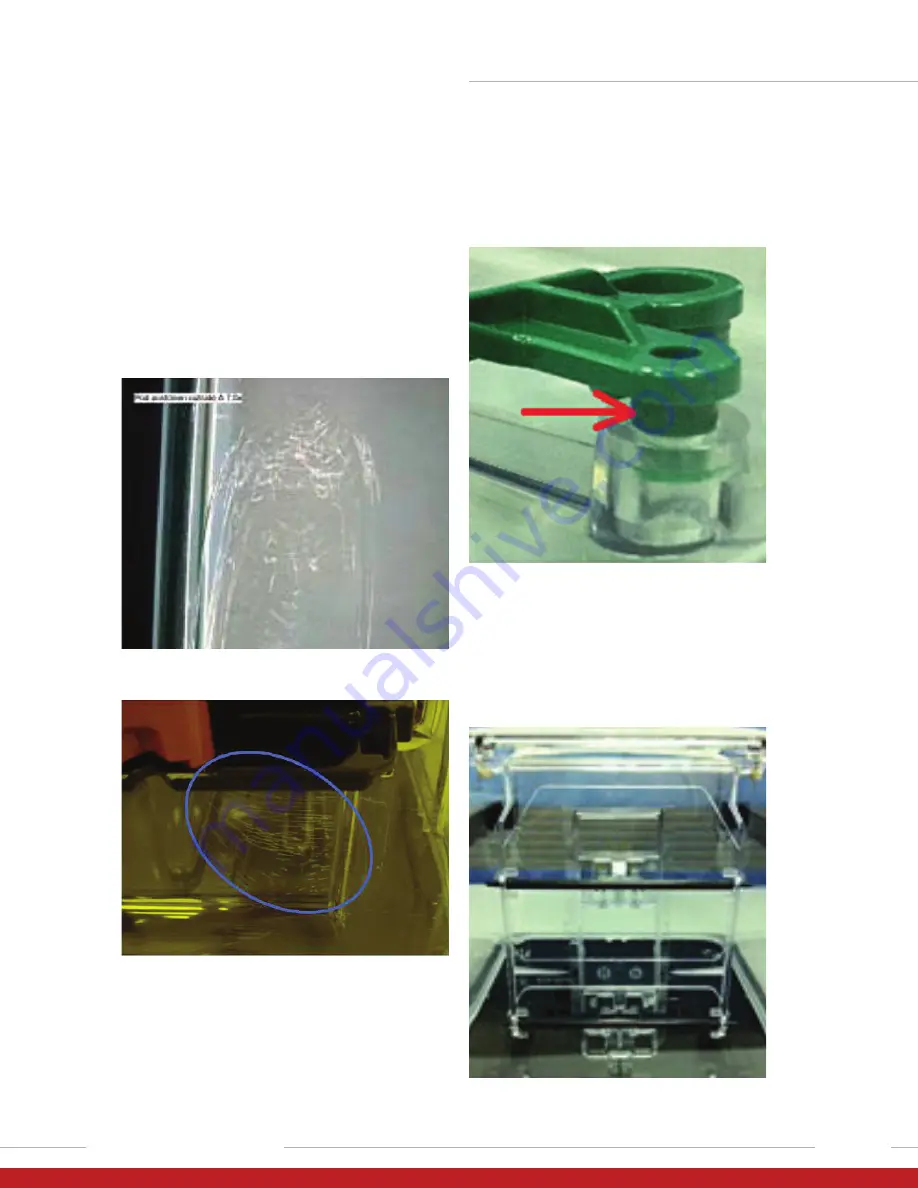

1. Visually inspect the shell surface—focusing especially

on the surfaces inside the mini environment—for

cracks, scratches, and evidence of chemical attack

such as crazing or pitting. Surface defects in the

plastic can make cleaning difficult and be a potential

source of particles sloughing off the surface of the

plastic. Crazing on the outside of the shells should

not significantly impact pod performance or lifetime.

Chemical attack/splash

Crazing on outside of shell—note how shallow the cracks are

2. Visually inspect for chipped and broken edges.

Focus on the knife edge where the door seals

and the bottom of the shell.

3. Visually inspect the CHD for warpage or improper

installation. There will be no gap between the CHD

and the shell in a proper installation. See the picture

below for an improperly installed CHD.

Cassette Hold Down (CHD) gap

4. Inspect the waferlock to ensure that all parts are

present (two PEEK screws, frame, two pivots,

waferlock, wheel). Check that the waferlock is

properly attached to both pivots and that the wheel

is properly seated.

Waferlock components