ENGLISH

11

• Remove

circlips (24) reaction rollers

(25) and roller pin (26).

•

Clean all exposed components with a

mild solvent.

•

Inspect all parts for damage.

•

Dry all components. Apply a thin coat

of molybdenum disulphide lubricant

as indicated.

5.2.2 The hydraulic drive unit

•

Check tightness of swivel manifold

post retaining screws (see 5.3.2) and

gland.

•

Pressurize the drive unit to maximum

pressure (

Advance

and

Retract

), and

check for any signs of leakage.

•

Any damaged components or seals

must be replaced.

•

Dry all components and apply a

thin coat of molybdenum disulphide

lubricant

as indicated.

5.3 Full

maintenance

Note:

Refer to the WCR4000 repair

parts sheet for detailed views of

components and subassemblies

referenced in sections 5.3.1 and 5.3.2.

5.3.1 The roller cassette

•

Strip down and clean all exposed

components with a mild solvent.

•

Drift out the spring pin holding the

cylinder retaining pin, and remove the

retaining pin.

•

Inspect all parts for damage.

•

Perform non destructive testing by

magnetic particle inspection on the

following components:

- Sideplates

- Cylinder locating plate

- Cylinder retaining pin

- Reaction roller bracket and pin

- Reaction rollers and roller pin

•

Dry all components. Apply a thin coat

of molybdenum disulphide lubricant

as indicated.

•

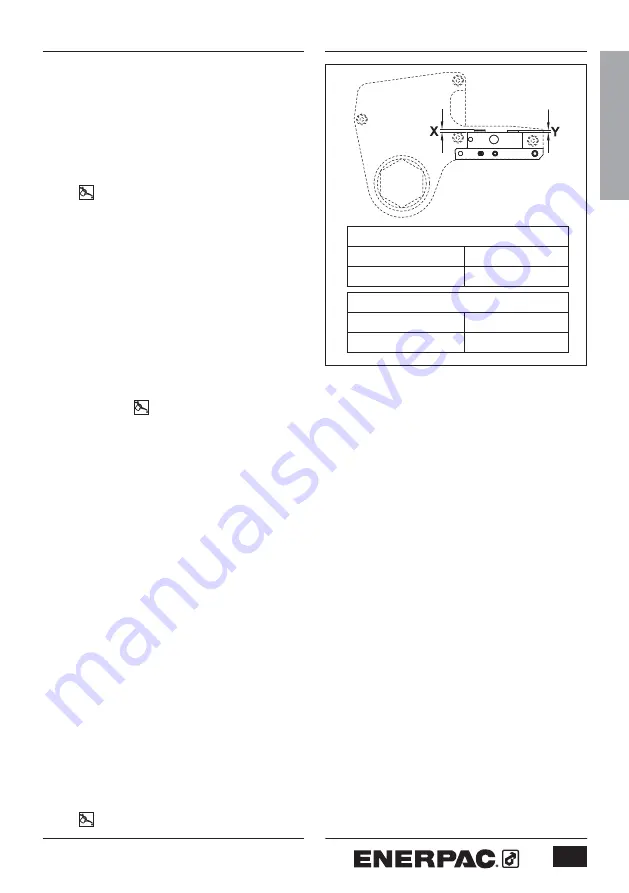

Check retaining pin height (X) and fail

safe pin height (Y). Refer to Fig. P.

•

Reverse the procedure to reassemble

the tool.

5.3.2 The hydraulic drive unit

•

Remove the circlip from the swivel

manifold block.

• Remove

the

hydraulic couplings.

• Remove

the

swivel manifold block

from the drive unit.

• Remove

the retaining screws and the

swivel manifold post.

•

Remove all ‘O’ rings from swivel

manifold post.

•

Carefully hold the cylinder body to

unscrew the cylinder gland.

•

Hold the two flat sides of the piston

rod with a spanner. The rod is located

at the spigot.

•

Remove the button head cap screw

from the piston.

•

Remove the piston rod from the

cylinder spigot end.

•

Remove the piston from the cylinder

gland end, using a suitable drift.

Retaining Pin Height - Dimension “X”

Metric

Imperial

5,00 mm

0.197 inch

Fail Safe Pin Height - Dimension “Y”

Metric

Imperial

3,00 mm

0.118 inch

Fig. P

Summary of Contents for WCR4000

Page 1: ...Instruction Sheet WCR4000 Roller Cassette L4021 English GB Rev B 09 2013...

Page 2: ...2...

Page 17: ...17 NOTES...

Page 18: ...18 NOTES...

Page 19: ...19 NOTES...