5.2.2 Two-point calibration vs. three-point calibration

Your choice of two-point calibration or three-point calibration depends on how many process gases you are

using.

Two-point

calibration

Two gases are used for calibration. Standard and most common applications require

only two calibration points to get the best accuracy. A two-point calibration produces

two calibration factors: K0 and K2. K1 is set to 0.

Three-point

calibration

Three gases are used for calibration. Three-point calibrations are less common. For

more information, see

.

Related information

5.2.3 Calibration gases

The calibration gases should match the main constituents of your process gas. The gases must cover the

lower and upper SG/MW range of the process gas and have similar compressibility characteristics.

Gas types and requirements

Analytical calibration gases are specified by purity grade or number of 9’s. “High purity” or “4.5 nines

(99.995%)” grades are good choices for calibrating the SGM.

For example, if the SGM is measuring the specific gravity of natural gas, use pure nitrogen and pure methane

as calibration gases.

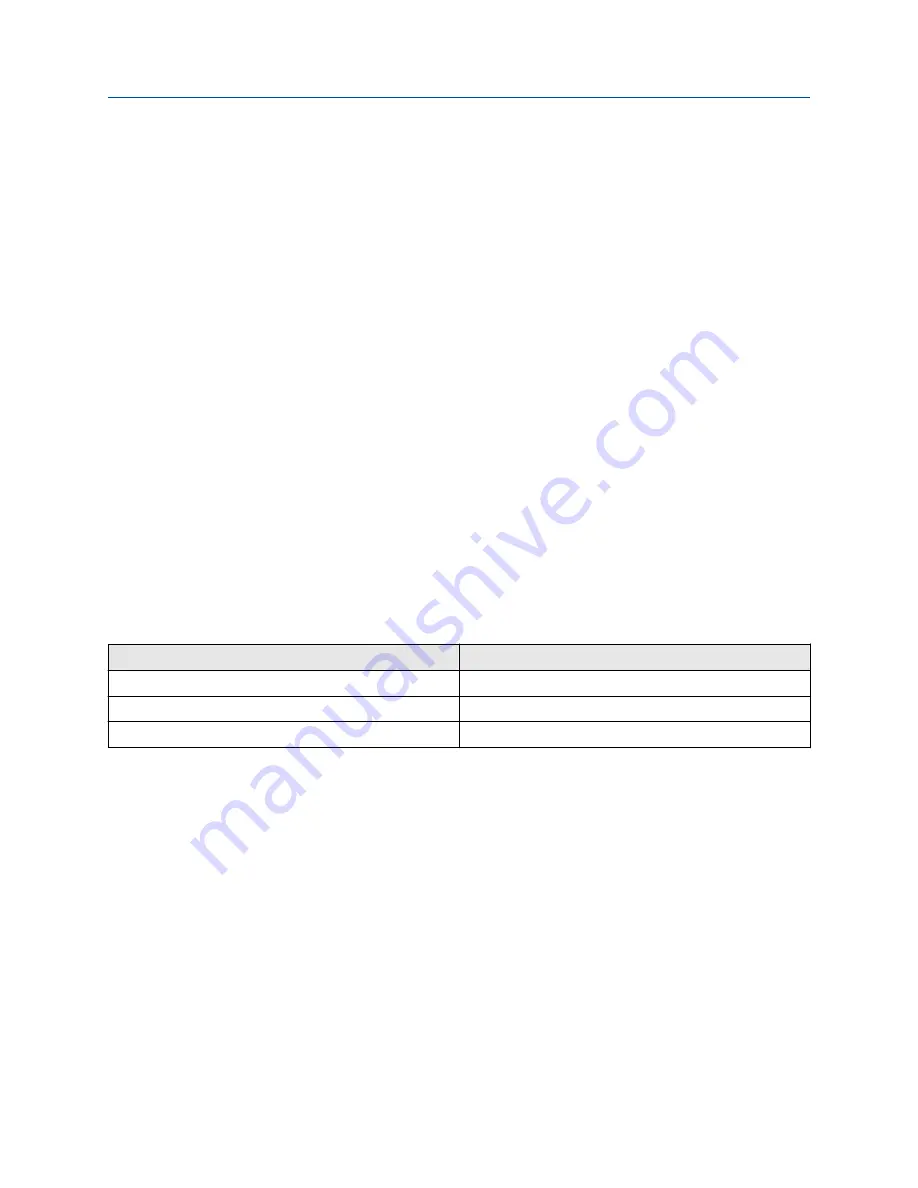

Table 5-1: Examples of calibration gases

Application

Two-point calibration gases

Natural gas

Methane and nitrogen

Hydrogen purity

Hydrogen and nitrogen

Fuel to air ratio

Methane and propane

Equipment requirements

•

Cylinders must have a gauge regulator and hose.

•

The hose needs to have a 0.25 in (6.4 mm) Swagelok

®

female connector.

•

The minimum gas bottle size for each of the calibration gases should be no less than 4.5 gallons (17 liters)

at a 20% higher of nominal pressure at the outlet of the regulator depending on the application.

Most gas suppliers can provide these items.

Purging and calibration

Configuration and Use Manual

March 2021

MMI-20020954

28

Micro Motion Gas Specific Gravity Meters (SGM)