Configuring BACnet Settings

The BACnet Network • 39

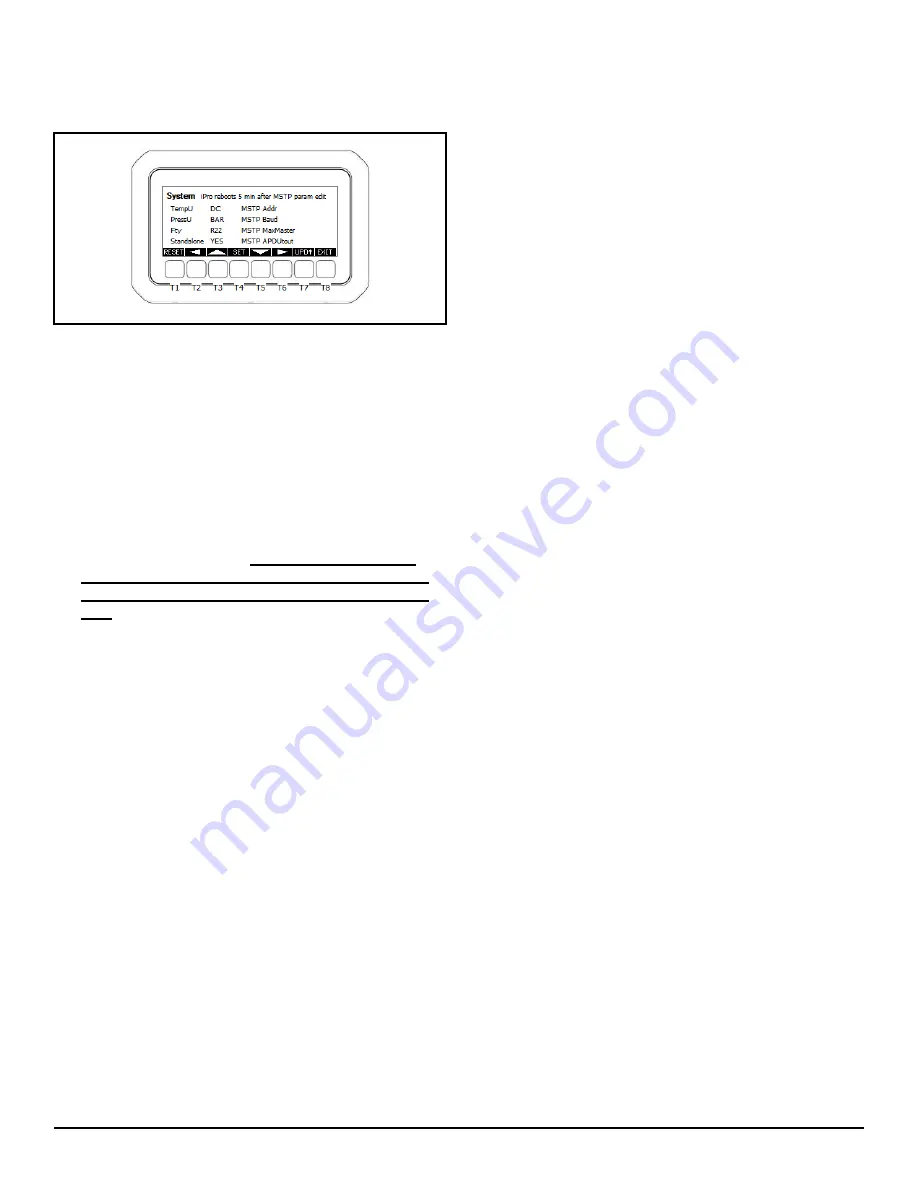

2. Press the T5 key to move the cursor to the

MSTP MaxMaster field

. Press T4 set to edit and use T3/T5

to move the values to the desired selection. The MSTP Max

Master is the highest network address that the controller will

poll for and attempt to discover. The Max Master parameter

should be set equal to the highest MAC address on the

MSTP network. For example: If 10 devices are all daisy

chained together in an RS485 network and the MAC

addresses are set as 1-10 sequentially, the BACnet Max

Master number of each controller should be set to 10. Press

T4 set to save the selection.

(Note: The case controller

saves and automatically reboots to re initialize with new

address after a period of 7 minutes, do not reboot manu-

ally.)

3. In the same menu, the MSTP APDU timeout parameter can

be edited (

MSTP APDUtout

). The recommended value of

this parameter is 30 seconds for all controllers on the

network. Use T3/T5 to navigate to the parameter and T4 to

edit and save.

Figure 12-6

- MSTP Max Master

Summary of Contents for iPro

Page 1: ...iPro Case Controller Installation and Operation Manual FW Version 1 01 026 1738 Rev 1 ...

Page 2: ......

Page 4: ......

Page 8: ......

Page 78: ...70 iPro Case Controller I O Manual FM V1 01 026 1738 Rev 1 17 Appendix iPro Connection Detail ...

Page 79: ......