47

TROUBLESHOOTING -

MANUAL ADVANCE RECHARGE CHECK

This check verifies proper operation of the position

switch, gear motor, brine tank fill, brine draw, recharge

flow rates, and other controller functions. Always make

the Initial Checks (See Page 45) and the Manual

Diagnostics (See Page 46) first.

1

. Display the

Diagnostics

screen, following the proce-

dure on Page 41.

2

. Press the DOWN (

6

) button to scroll through the list

until

Valve position switch

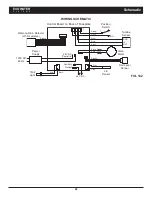

is displayed (See Figure

160).

Diagnostics

Current position:

Service

Requested position:

Service

FIG. 161

5

. Verify that the valve position indicator on the motor

cam agrees with the position displayed on the screen

6

. Remove the brinewell cover.

7

. With the Diagnostics screen displayed, press the

RIGHT (

4

) button once to advance the valve from

Service

to

Fill

.

8

. Shine a flashlight into the brinewell and observe fill

water entering the tank.

9

. If water does not enter the tank, look for an obstruct-

ed nozzle / venturi, fill flow plug or brine tube (See

Figure 154 on Page 43).

10

. After verifying fill, press the RIGHT (

4

) button once

to move the valve into

Brine

*. A slow flow of water

to the drain will begin. Verify brine draw from the

brine tank by shining the flashlight into the brinewell

to observe a noticeable drop in the liquid level.

*

If the 2nd Backwash option is set “On” (See Page 37), the

valve will enter backwash and fast rinse before brine.

Diagnostics

Valve position switch:

Closed

Turbine count:

0

FIG. 160

3

. Verify that when the switch plunger is down (into one

of the detents on the valve motor cam), this screen

reads

Open

. When the valve cam is rotating (for

example, after Step 7, below) , the switch plunger will

be up and this screen should read

Closed

.

4

. Press the UP (

5

) button to scroll through the list until

Current position

is displayed (See Figure 161).

11

. If the unit does not draw brine, check for:

=

Dirty or defective nozzle / venturi (See Page 43)

=

Nozzle / venturi not seated on the gasket or gas-

ket not sealing properly

=

Restriction in valve drain, causing back pressure

(bends, kinks, elevated too high, etc.)

=

Obstruction in valve or brine tubing

=

Internal valve fault (obstructed outlet disc, wave

washer faulty etc.)

12

. With the Diagnostics screen displayed, once again

press the RIGHT (

4

) button to advance the valve to

Backwash

.

13

. Look for a fast flow of water from the drain hose. If

flow is slow, check for a plugged top distributor,

backwash flow plug or drain hose

14

. With the Diagnostics screen displayed, once again

press the RIGHT (

4

) button to advance the valve to

Fast rinse

.

15

. Again, look for a fast flow of water from the drain

hose. Allow the unit to rinse for several minutes to

flush out any brine that may remain from the brine

cycle test.

16

. With the Diagnostics screen displayed, once again

press the RIGHT (

4

) button to return the valve to

the

Service

position.

IMPORTANT:

Always return the valve to the

Service

position before exiting this procedure.

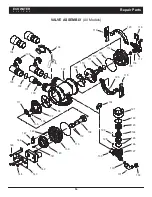

OTHER SERVICE

Hard Water Bypass

(Hard water “bleeds” into condi-

tioned water supply):

1

. Faulty inlet disc, seal or wave washer (See Pages 54

and 55).

2

. Missing or faulty o-ring(s) at valve connection to riser

pipe.

Water Leaks from Drain Hose

during service:

1

. Faulty inlet disc, seal or wave washer.

2

. Faulty o-ring on inlet disc shaft.

3

. Faulty outlet disc, seal or wave washer.

Flooded Salt Tank

:

1

. Nozzle / venturi plugged.

2

. Faulty valve seals.

3

. Restricted or plugged backwash / fast rinse controls.

4

. Restricted or plugged drain line.

Water Has Salty Taste

:

1

. House water pressure low. Adjust well pump.

2

. Partially restricted valve drain hose, top distributor,

backwash flow plug, resin tank internal riser pipe, or

bottom distributor.

3

. Backwash and fast rinse times have been reduced

from default settings.

4

. Wrong model code.

ECOWATER

S Y S T E M S

Service Information