2

SAFETY GUIDES

Follow the installation instructions carefully. Failure to

install the EcoWater Systems conditioner/refiner proper-

ly

voids the warranty.

Before you begin installation, read this entire manual.

Then, obtain all the materials and tools you will need to

make the installation.

Check local plumbing and electrical codes.

The

installation must conform to them.

Use only lead-free solder and flux

for all sweat-solder

connections, as required by state and federal codes.

Use care when handling the EcoWater Systems condi-

tioner/refiner. Do not turn upside down, drop, or set on

sharp protrusions.

Do not locate the EcoWater Systems conditioner/refiner

where freezing temperatures occur. Do not attempt to

treat water over 120°F.

Freezing, or hot water dam-

age voids the warranty.

Avoid installing in direct sunlight. Excessive sun heat

may cause distortion or other damage to non-metallic

parts.

The EcoWater Systems conditioner/refiner requires a

minimum water flow of 3 gallons per minute at the inlet.

Maximum allowable inlet water pressure is 125 psi.

If daytime pressure is over 80 psi, nighttime pressure

may exceed the maximum. Use a pressure reducing

valve if necessary (Adding a pressure reducing valve

may reduce the flow).

The EcoWater Systems conditioner/refiner works on

24V DC

electrical power, supplied by a direct plug-in

power supply (included). Be sure to use the included

power supply, and plug it into a nominal

120V, 60 Hz

household outlet that is in a

dry location only

, ground-

ed and properly protected by an over current device

such as a circuit breaker or fuse.

This system is not intended to be used for treating water

that is microbiologically unsafe or of unknown quality

without adequate disinfection before or after the system.

If conditioner/refiner is being used to reduce barium

and/or radium 226 and 228, please verify performance

by contacting Legend Technical Services, an independ-

ent laboratory, at 1-800-949-8220 for testing treated

water supply, or check the water testing section of your

local phone directory.

FCC NOTICE

NOTE:

This equipment has been tested and found to

comply with the limits for a Class B digital device, pur-

suant to Part 15 of the

FCC

Rules. These limits are

designed to provide reasonable protection against

harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio fre-

quency energy and, if not installed and used in accor-

dance with the instructions may cause harmful interfer-

ence to radio communications. However, there is no

guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful inter-

ference to radio or television reception, which can be

determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by

one or more of the following measures:

=

Reorient or relocate the receiving antenna.

=

Increase the separation between the equipment and

receiver.

=

Connect the equipment into an outlet on a circuit dif-

ferent from that to which the receiver is connected.

=

Consult the dealer or an experienced radio/TV tech-

nician for help.

Changes or modifications not expressly approved by

EcoWater Systems could void the user’s authority to

operate the equipment.

This device complies with

Industry Canada

Standard

RSS-210. Operation is subject to the following two con-

ditions: (1) this device may not cause interference, and

(2) this device must accept any interference, including

interference that may cause undesired operation of the

device.

Ce dispositif est conforme avec la norme CNR-210

d’Industrie Canada

. Le fonctionnement du dispositif

est sujet aux deux conditions suivantes: (1) le dispositif

ne doit pas causer de brouillage, et (2) le dispositif doit

accepter tous brouillages, incluant tous brouillages qui

peut nuire au bon fonctionnement du dispositif.

European Directive 2002/96/EC requires all

electrical and electronic equipment to be dis-

posed of according to Waste Electrical and

Electronic Equipment (WEEE) requirements.

This directive or similar laws are in place

nationally and can vary from region to region.

Please refer to your state and local laws for

proper disposal of the equipment.

TABLE OF CONTENTS

Page

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications & Performance Claims . . . . . . . . . . 5-6

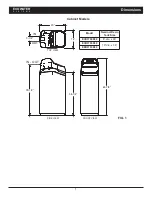

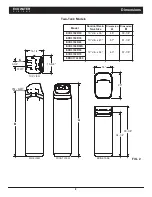

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

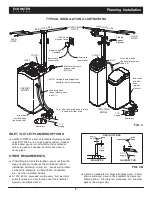

Planning Installation . . . . . . . . . . . . . . . . . . . . . . . . . 9

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

Wi-Fi Systems: Setup, Connect & Registration . 13-16

Non-Wi-Fi Systems: Setup & Remote . . . . . . . . 17-27

Conditioner/Refiner Operation . . . . . . . . . . . . . . 28-41

Service Information . . . . . . . . . . . . . . . . . . . . . . 42-47

Adding Salt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . 45

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-55

ECOWATER

S Y S T E M S

Table of Contents & Safety Guides