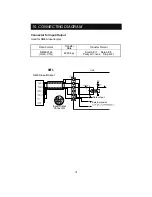

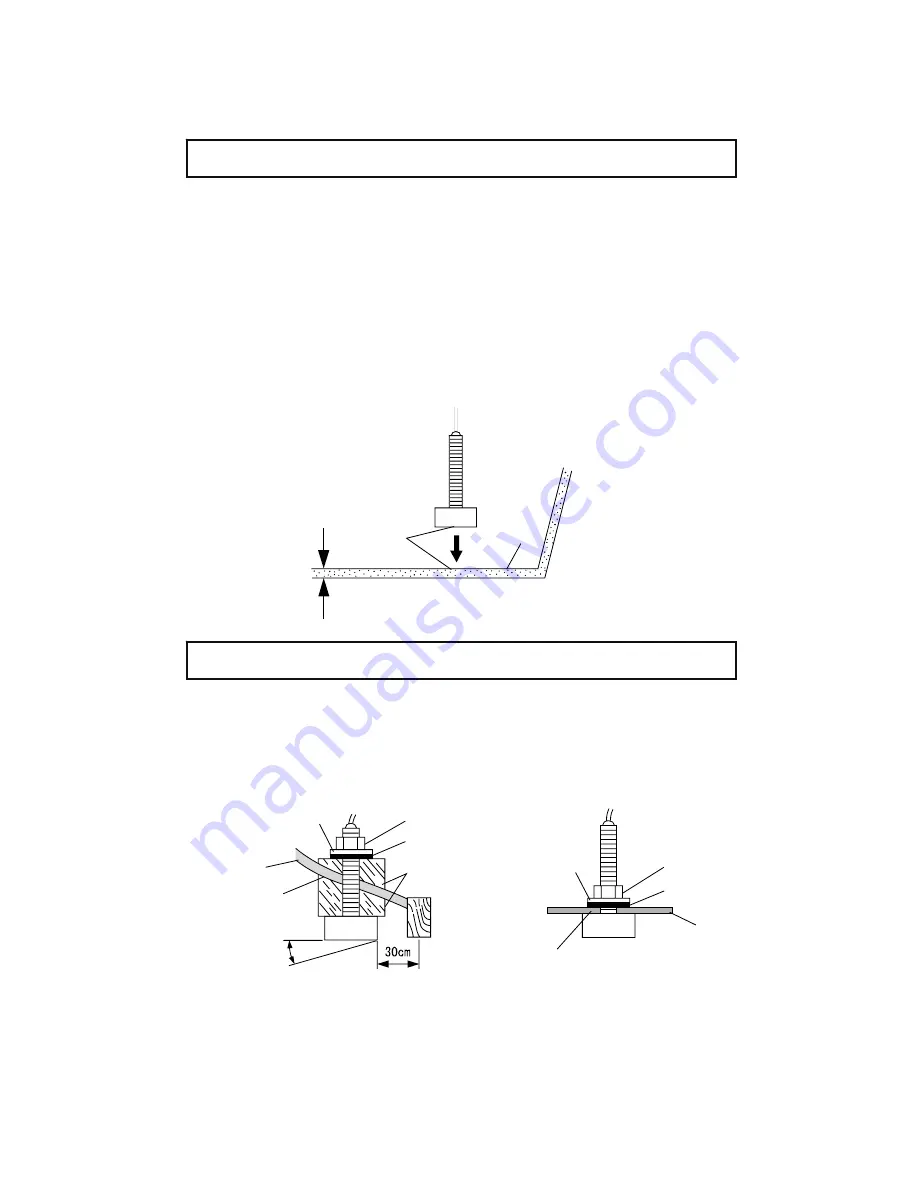

Effective for FRP vessels with single hull layer of 10mm or less.

Look for the best picture location before the fixation by putting adequate water on

the transducer surface and vessel bottom followed by pressing the transducer onto

the vessel bottom.

(

1

)

Polish the adhesive surface (transducer bottom surface and vessel bottom) well

with sandpaper(#240 or around) and alcohol in order to remove oil, water, and

dirt on the surface.

(

2

)

Put silicon bond on the adhesive surface (transducer bottom surface and vessel

bottom) and press firmly for the bonding so that no air bubble is contained inside.

9-2. THRU-HULL

9-1. INSIDE-HULL

Single layer

(

10mm or less

)

vessel bottom

Bond

Vessel

bottom

Transom

(

1

)

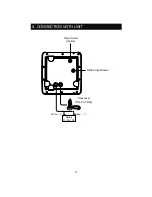

Make a hole of approx.

φ

23 at the vessel bottom. (Alminum vessels are not

subject to the installation for the risk of corrosion.)

(

2

)

Insert the screw part of transducer into the hole and fix it with 1pc cork washer,

1pc washer, and 1pc nut. (Extra cork washer is for spare.)

Execute the water proof care for the junction part.

For tilted hull, use a block etc to face directly to the vessel bottom.

Keep the inclination of transducer surface

below 10

°

or less.

Washer

Nut

Cork

Hull

Block

Put the seal at joint

point for waterproof.

Put the seal at joint point for waterproof.

Hull

Cork

Nut

Washer

14