4

Instruction Booklet

IB 52-01-TE

Effective October 2010

Instructions for the Eaton Type CM52

Network Protectors 800 to 4500 Amperes

EATON COrPOrATION www.eaton.com

4 IB -52-01-TE

Effective 11/05/08 (super cedes 11/19/03) IB 52-01-TE

4

the block , while all customer connections can be

made on the front portion of the blocks. There is

a wire designation strip that id entifi es the wi re

number to its port. This terminal block only

requires that the wire be stripped approximately

¼”, inserted into the wire clamp area and the top

recessed screw tightened to ensure a secure joint.

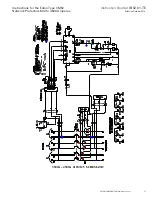

Fig. 6

Relay Module Panel Opened

NOTE: All of the secondary conta ct wi ring

has been factory made from the breaker

secondary disconnecting to the DIN rail

terminal block. Two 1.00” NPT half-pipe

couplings are welded to the enclosure body,

one on each side, adjacent to the relay module

area. There is a large opening on the left and

right hand side sheets of the relay module to

facilitate wire routings from the pipe plug to

the secondary terminal block

.

S ECTION III – OPERATION

PROCEDURE

TO

REMOVE

THE

DRAWOUT UNIT FROM HOUSING

When the enclosure is not attached to a transformer, the

enclosure m ust be supported in a way that will prevent

tipping forward when the door is open and the draw out unit

is on the extension rails.

3.1.1 To Open Door

Loosening all the bolts, starting with the bolts on

the hinged side, opens the quick opening

enclosure. The bolts are loosen ed until the bolts

are completely disengag ed from the housing

support.

3.1.2

Levering Circuit Breaker

The circuit break er is now ready to be lev ered.

With the circuit break er OPEN, the lev ering

device access door can be raised. The levering

device is hand operated under a stand ard 3/8”

square drive speed wren ch, which is provided.

As long as the access door is raised, the circuit

break er is held trip free. Begin by rotating the

levering-in s crew to the full count erclo ckwise

(DISCONNECT) position.

Fig. 7

Inserting Levering –In Crank

Note: Levering-in door must be co mpletely

closed after cran k removal to insure proper

operation.

The position of the circuit breaker within its com partm ent is

dictated by color-coded position indicators (Red = Connect,

Yellow = Test, Green = Disconnect). To rem ove the circuit

breaker from its com partm ent, follow the procedure j ust

described using a counterclockwise m otion.