Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07

59

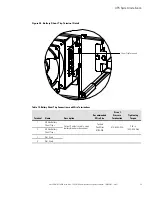

Figure 29. Battery Shunt Trip Terminal Detail

Shunt Trip Terminals

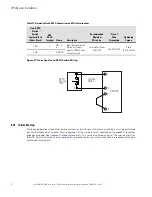

Table 15. Battery Shunt Trip Connections and Wire Terminations

Terminal

Name

Description

Recommended

Wire Size

Size of

Pressure

Termination

Tightening

Torque

1

48 Vdc Battery

Shunt Trip +

Output: Contacts used to open

battery breaker or disconnect

Twisted

Pair Wires

#18 AWG

#14-#30 AWG

2 lb in

(0.22-0.25 Nm)

2

48 Vdc Battery

Shunt Trip –

3

Not Used

4

Not Used

Summary of Contents for 93PM Series

Page 4: ......

Page 138: ...16400022707 164000227 07 ...