38 Maintenance

On dead roller tunnels, clean and lubricate the conveyor chains. Check the

chains and adjust as needed. Check for overall wear on dead roller guide rails

and starter rails. Repair as needed.

Check the condition of the silicone covering on the rollers. Repair or replace as

necessary.

Check and clean the motor-to-conveyor drive chain. Adjust tension as needed.

Check the intake screens of the shrink tunnel and clean them as necessary.

Check for loose fasteners. Tighten as necessary.

Check the condition of the power cord for wear. Especially if it is exposed to

traffic.

Check that the seal bars and tunnel are able to maintain the set temperatures. If

not, refer to the Troubleshooting section of this User Guide for instruction.

Check that you are able to vary conveyor speeds within required ranges. If not,

refer to the Troubleshooting section of this User Guide for instructions.

Check the condition of all warning and instruction labels. Replace as necessary.

L-Sealer Maintenance and Replacement

Film Roll Support Rollers

Make sure rollers stay clean and grease free. If you should have to clean the rollers,

simply wipe them down with a clean lint free cloth. If a more thorough cleaning is

necessary wipe the rollers down with a mild detergent and water and let dry.

Never use

harsh or abrasive cleaners or chemical agents when cleaning the rollers.

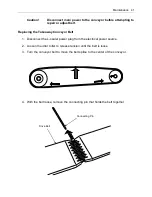

Silicone Rubber and Felt Seal Pad Replacement

Occasionally it will be necessary to replace the silicone rubber or felt sealing pads. Seal

pads are designed with a channel to make them easy to install and replace. Seal pads

should be replaced if the following symptoms are observed.

Gaps in the seal

Weak seals

Improper film cutoff

Excessive sealing pressure required

To replace a silicone rubber or felt pad, pull the old pad out of the channel and replace

with the new silicone rubber or felt pad, pressing it into place in the channel.

NOTE:

Some silicone rubber pads come covered in talcum powder. If so,

clean the pads with a mild solvent.

Summary of Contents for Combination EC Series

Page 2: ......

Page 4: ......

Page 73: ...Appendix A Electrical Schematic 73 Electrical Schematic L Sealer ...

Page 81: ......