- 58 -

Simplified R Function

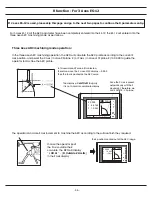

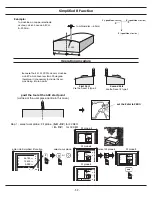

In case 2 Axes ES-12 is used, we must first reset the Z Dial to simulate the initial Z position at the ARC's start point

**** Only for 2 Axes DRO, not valid if a 3 Axes DRO is used ***

** Posit the Tool at start point of the ARC to be machined **

Set the Z axis Dial

to ZERO ( 0.00 )

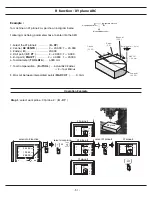

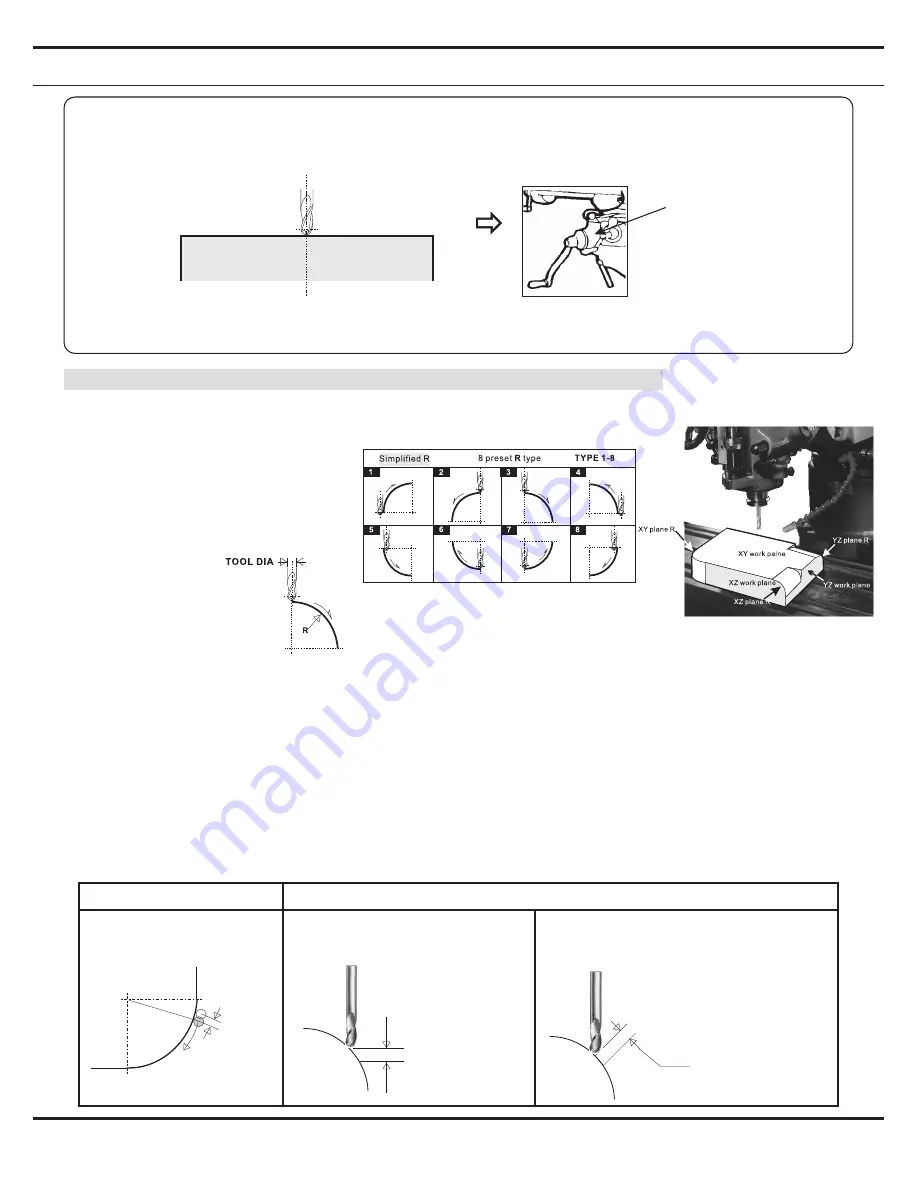

1. Select the work plane - XY, XZ or YZ plane R

2. Select the R type (

R type

) - Type 1 to 8

3 Input R's Radius (

R

)

4. Enter to Tool Diameter

(

TOOL DIA

)

Following parameters needed to enter into the DRO for simplified R machining

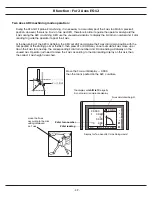

5. Machining STEP increments ( Only when for 2 axes ES-12 is used or machining the XY plane R )

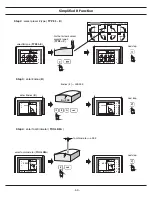

Since in the 2 axes ES-12, there is no Z axis available, in order to make the machining of XZ and YZ plane R

possible, we need to simulate the Z axis position by mathematical method, also, we need to simulate the

Z up/down increments by the UP or DOWN key press so that the DRO can calculate the XZ / YZ arc machining

position accordingly, this parameter is to specify how the Z position increment when UP or DOWN key is pressed.

When machining the XZ and YZ plane R in 3 axes ES-12, no need to enter this Machining STEP increments,

it is because the DRO can calculate the X or Y machining positions and set those points to zero to guide the

operator to machine the ARC according to the current Z position. In case the Z position are out of the ARC's

Z position range, an warning message [ r. OU LI] - R is outside the Z limit is displaying on the Z axis of the ES-12.

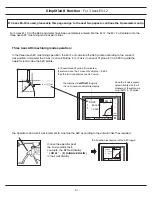

For XY plane R, Max. distance

between interoplated points is

to be specified as the machining

STEP increments

XY

plane

R

XZ / YZ

plane

R

(

for 2 Axes ES-12 only, not for 3 Axes ES-12

)

Fixed Z incremets

per UP or DOWN pkey

press

Z STEP =

For XZ/YZ plane R, the Z STEP parameter

is the Z step increments per UP or DOWN

key press. The Z increment distance is fixed

and specified by this

parameter.

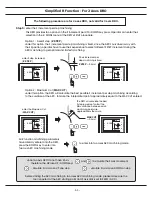

For XZ/YZ plane R, if the R MODE parameter of SETUP

is selected to be MAX CUT, the DRO will calculate the

Z step increments per UP or DOWN key press so that

the Max. distances between each machining step

are approximately the same for a

smoother ARC machining.

max. distance

between

interpolated points

MAX CUT=

MAX CUT=

max. distance

between

interpolated points

Summary of Contents for ES-12

Page 8: ...1 Basic Fucntions Basic Functions BASIC...

Page 15: ...8 Built in Calculator Calculator...

Page 27: ...20 REF datum memory...

Page 31: ...24 LHOLE tool positioning for the Line Holes...

Page 35: ...28 INCL Inclined angle tool positioning...

Page 40: ...33 PCD tool positioning for Pitch Circle Diameter...

Page 45: ...R R R 38 tool positioning for ARC machining...

Page 63: ...R R R 56 Simplified R function...

Page 73: ...66 Shrinkage Calculation L L X 1 005...

Page 91: ...Parameter Setup B 1 SET UP...