Parameters Setup Procedure - RAD/DIA

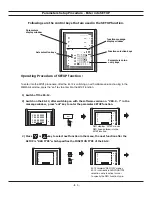

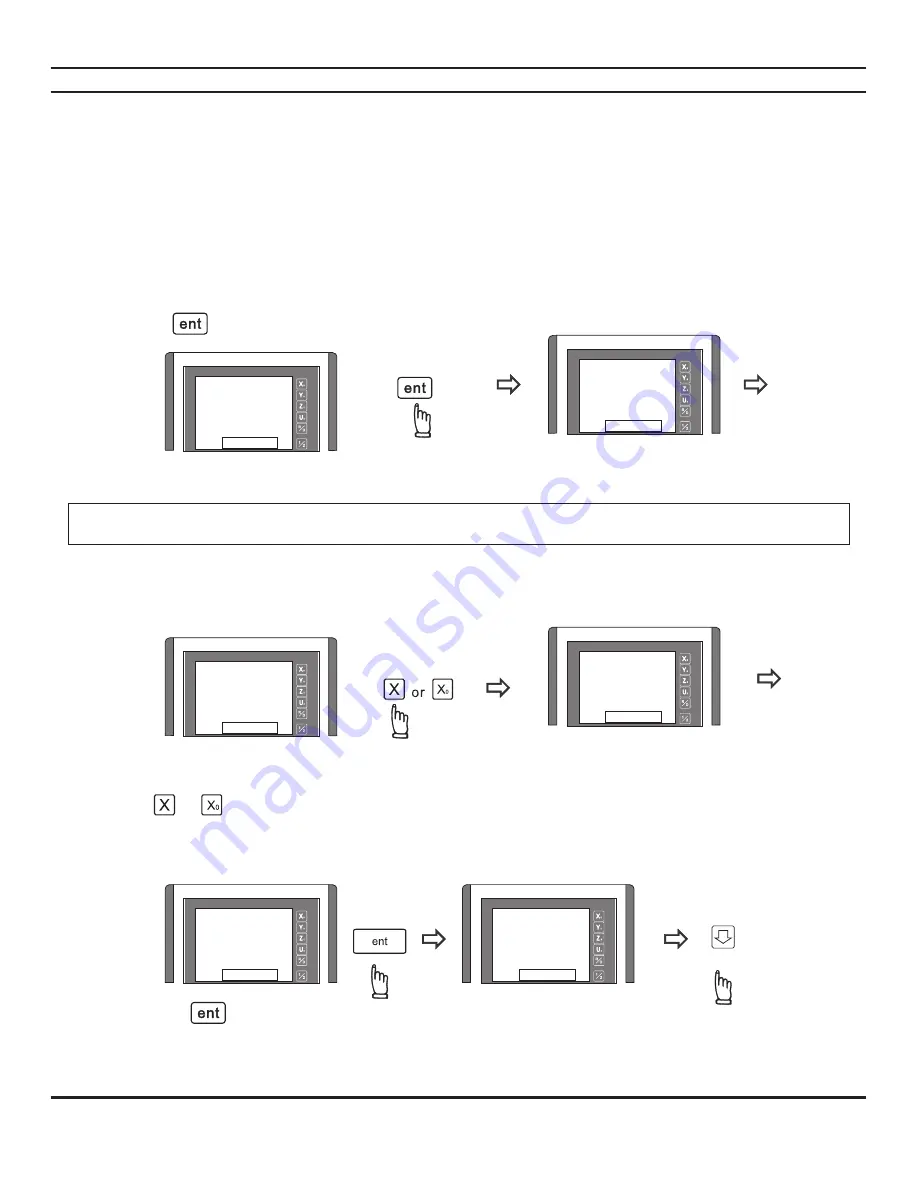

For example, if you want to make a change to the current 'rAd' display mode of the X axis, procedure are as follows

Press or to specify the X axis, if the current display mode is 'rAd', it will swap to 'dIA' after the key

press, and vice versa. The same procedure applied to Y , Z and U axis

The X axis display mode have

been changed to Diameteral

display mode

then press to exist from

"RESOLU" menu and return to

the top level menu

Press to select the "RAD/DIA" selection menu

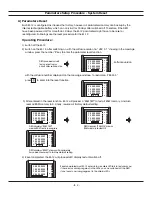

RAD/DIA menu is designed to allow operator to select the diemension display in Radius ( nromal display ) or

Diameteral ( 2X the real dimension ) display. This feature is very useful for lathe application. All axes in the DRO

can be configrured to DIA ( 2X ) display. If the axis display is configured as DIA display, a 'd' character will be

displayed at the first digit display of the axis to have the user easily recongise the display is in DIA mode. All

DRO functions that are normally used in lathe application are tested and confirmed to work properly under the

DIA display, such as INCL.

The RAD/DIA of the display axis are specified by 'rAd' or 'dIA' :

'rAd' - Radius mode display selected, axis shows the real dimension reading

'dIA' - Diameteral mode display selected, axis shows 2X( 2 times ) the real dimension reading.

The 'rAd' display means Radius

display mode are selected in

the respective axis.

'rAd' represent Radius display mode, 'dIA' represent Diameter display mode. Press the "ent" key to make your selection

- B. 11 -

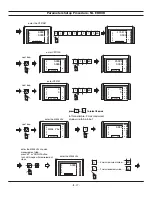

selection done

go to next menu

X

Y

Z

U

RAD/DIA

X

Y

Z

U

RAD/DIA

X

Y

Z

U

SEL.AXIS

rAd

rAd

rAd

rAd

X

Y

Z

U

SEL.AXIS

rAd

rAd

rAd

rAd

X

Y

Z

U

SEL.AXIS

dlA

rAd

rAd

rAd

X

Y

Z

U

SEL.AXIS

dlA

rAd

rAd

rAd

Summary of Contents for ES-12

Page 8: ...1 Basic Fucntions Basic Functions BASIC...

Page 15: ...8 Built in Calculator Calculator...

Page 27: ...20 REF datum memory...

Page 31: ...24 LHOLE tool positioning for the Line Holes...

Page 35: ...28 INCL Inclined angle tool positioning...

Page 40: ...33 PCD tool positioning for Pitch Circle Diameter...

Page 45: ...R R R 38 tool positioning for ARC machining...

Page 63: ...R R R 56 Simplified R function...

Page 73: ...66 Shrinkage Calculation L L X 1 005...

Page 91: ...Parameter Setup B 1 SET UP...