F 100 8

8

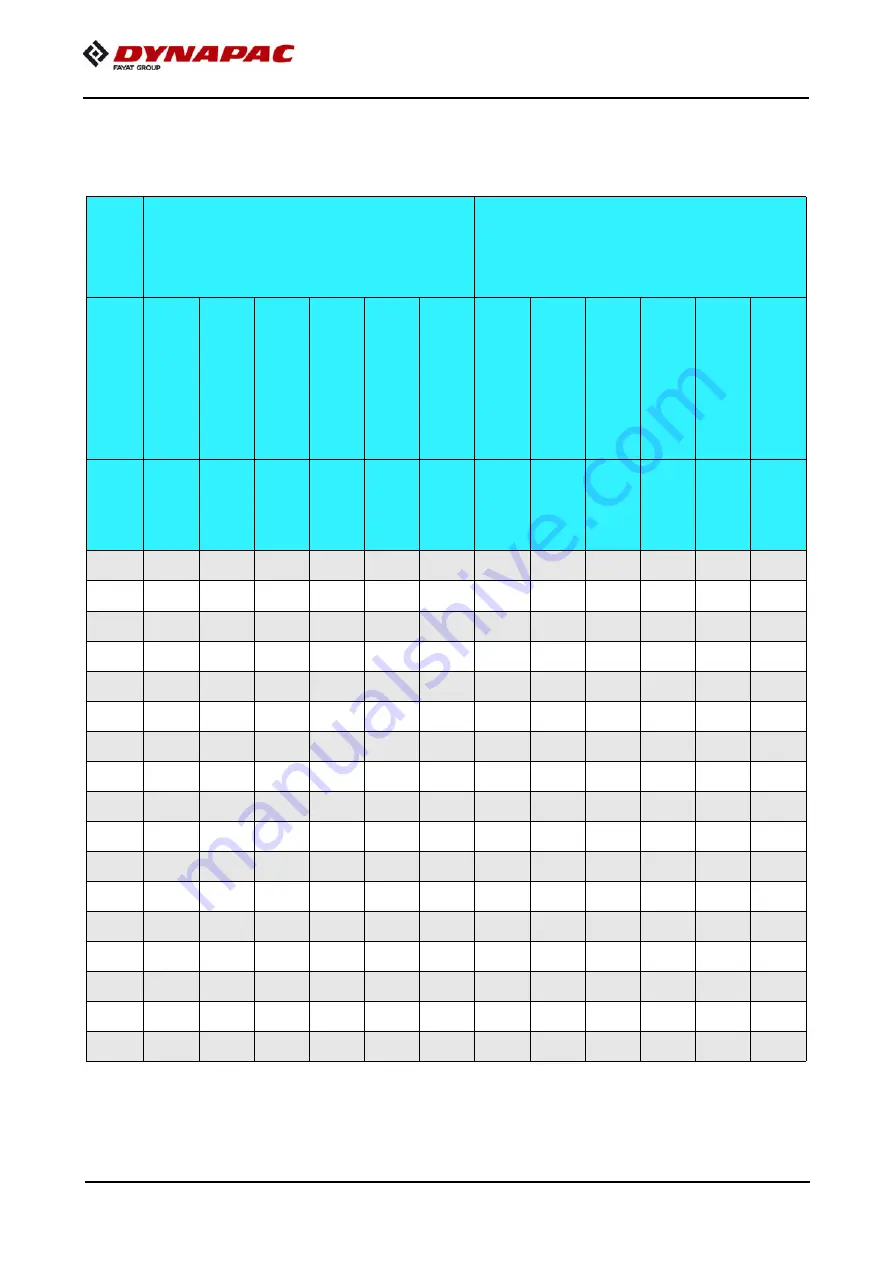

Bolts - torques

8.1

Standard metric threads - strength class 8.8 / 10.9 / 12.9

Treatment

dry/lightly oiled

Molykote ®

Torque (Nm)

Permitted

deviatio

n (+/- N

m

)

Torque (Nm)

Permitted

deviatio

n (+/- N

m

)

Torque (Nm)

Permitted

deviatio

n (+/- N

m

)

Torque (Nm)

Permitted

deviatio

n (+/- N

m

)

Torque (Nm)

Permitted

deviatio

n (+/- N

m

)

Torque (Nm)

Permitted

deviatio

n (+/- N

m

)

Strength

class

8.8

8.8

10.9

10.9

12.9

12.9

8.8

8.8

10.9

10.9

12.9

12.9

M3

1

0,3

1,5

0,4

1,7

0,4

1

0,3

1,4

0,4

1,7

0,4

M4

2,4

0,6

3,5

0,9

4

1

2,3

0,6

3,3

0,8

3,9

1

M5

5

1,2

7

1,7

8

2

4,6

1,1

6,4

1,6

7,7

1,9

M6

8

2,1

12

3

14

3

7,8

1,9

11

2,7

13

3,3

M8

20

5

28

7,1

34

8

19

4,7

26

6,6

31

7,9

M10

41

10

57

14

70

17

37

9

52

13

62

16

M12

73

18

97

24

120

30

63

16

89

22

107

27

M14

115

29

154

39

195

45

100

25

141

35

169

42

M16

185

46

243

61

315

75

156

39

219

55

263

66

M18

238

60

335

84

402

100

215

54

302

76

363

91

M20

335

84

474

119

600

150

304

76

427

107

513

128

M22

462

116

650

162

759

190

410

102

575

144

690

173

M24

600

150

817

204

1020

250

522

131

734

184

881

220

M27

858

214

1206

301

1410

352

760

190

1067

267

1281

320

M30

1200

300

1622

405

1948

487

1049

262

1475

369

1770

443

M33

1581

395

2224

556

2669

667

1400

350

1969

492

2362

590

M36

2000

500

2854

714

3383

846

1819

455

2528

632

3070

767

Summary of Contents for F1200C

Page 2: ...www dynapac com...

Page 10: ...8...

Page 24: ...A 2...

Page 31: ...B 7 4 Safety devices 4 5 6 7 8 8 2 1 9 3 10...

Page 34: ...B 10 5 2 Permissible approach angle max 15 max 10...

Page 41: ...B 17 xxxxxxxxxxxxxxxxx 32 30 31...

Page 52: ...B 28...

Page 74: ...C 10 12 22...

Page 78: ...D 10 12 4 15 16 18 14 13 17 12 11 10 10 19...

Page 80: ...D 10 12 6 15 16 18 14 13 17 12 11 10 10 19...

Page 82: ...D 10 12 8 15 16 18 14 13 17 12 11 10 10 19...

Page 84: ...D 10 12 10 21 20 23 22...

Page 86: ...D 10 12 12 25 24 27 26...

Page 88: ...D 10 12 14 25 24 27 26...

Page 90: ...D 10 12 16 29 30...

Page 92: ...D 10 12 18 32 31...

Page 94: ...D 10 12 20 33...

Page 96: ...D 10 12 22 35 34...

Page 98: ...D 10 12 24 36 38 37...

Page 100: ...D 10 12 26 40 39...

Page 102: ...D 10 12 28 42 41...

Page 104: ...D 10 12 30 44 43...

Page 106: ...D 10 12 32 45...

Page 108: ...D 10 12 34 51 56 58 57 59...

Page 110: ...D 10 12 36 51 56 58 57 59...

Page 112: ...D 10 12 38 Flame monitoring o 73 71 72 70...

Page 114: ...D 10 12 40 77 74 75 76...

Page 118: ...D 10 12 44 95 90 91 92 93 94...

Page 120: ...D 10 12 46 95 90 91 92 93 94...

Page 122: ...D 10 12 48 4 Remote control 103 104 101 106 100 102 105 107 108 109...

Page 124: ...D 10 12 50 103 104 101 106 100 102 105 107 108 109...

Page 126: ...D 10 12 52 103 104 101 106 100 102 105 107 108 109...

Page 128: ...D 10 12 54 103 104 101 106 100 102 105 107 108 109...

Page 130: ...D 10 12 56 5 Malfunctions 5 1 Error code query for engine 3 1 2...

Page 144: ...D 30 12 12 m Tighten all assembly parts properly after setting up...

Page 152: ...D 30 12 20...

Page 157: ...D 40 12 5 1 3 7 8 6 6 7 7 6 2 4 9 5...

Page 160: ...D 40 12 8 1 3 7 8 6 6 7 7 6 2 4 9 5...

Page 163: ...D 40 12 11 1 2...

Page 165: ...D 40 12 13 6 1 2 3 4 5...

Page 167: ...D 40 12 15 4 6 6 6 1 2 5 3...

Page 171: ...D 40 12 19 2 3 2 2 1 4...

Page 173: ...D 40 12 21 1 8 9 8 8 6 4 2 3 5 7 10 13 11 12...

Page 176: ...D 40 12 24 1 2...

Page 178: ...D 40 12 26 1 4 5 10 10 7 3 2 9 6 8 12 10 13 14 16 15 11 4 4 11 11...

Page 186: ...D 40 12 34...

Page 205: ...F 3 12 1 F 3 12 Maintenance conveyor 1 Maintenance conveyor...

Page 211: ...F 4 12 1 F 4 12 Maintenance auger assembly 1 Maintenance auger assembly...

Page 233: ...F 6 12 1 F 6 12 Maintenance hydraulic system 1 Maintenance hydraulic system...

Page 247: ...F 7 12 1 F 7 12 Maintenance drive unit 1 Maintenance drive unit...

Page 260: ...F 7 12 14...

Page 261: ...F 8 12 1 F 8 12 Maintenance electrical system 1 Maintenance electrical system...

Page 276: ...F 8 12 16...

Page 278: ...F 11 12 2 2 7 1 3 5 6 6 4...

Page 284: ...F 11 12 8...

Page 285: ...F 100 1 F 100 Tests stopping 1 Tests checks cleaning stopping...

Page 294: ...F 100 10...

Page 296: ...www dynapac com...