4

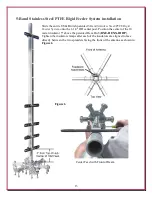

antenna pattern control. This revolutionary Rigid Feeder attaches directly to the outside of the full-

size 1-1/4" fiberglass Center Post. It is no longer necessary to drill or slice up a center post -

weakening it - to attach or protect older coaxial cable feeders with homebrew or terminal strip

connections. The use of this balanced feeder system maintains optimal pattern, where other

antennas have compromised unbalanced coaxial feeders with potentially distorted patterns.

The integral center insulators with the unique serpentine wire grip assure long, reliable

performance. The pre-assembled and tested Five Band Stainless Steel/PTFE Rigid Feeder System is

also ideal for retrofitting to other, older hexagonal beam designs using the DX Engineering wire

element dimensions - or with your own hex antenna with appropriate testing and modifications.

At the center of the new

HEXXAGONAL BEAM Mark 2

is the exclusive

DX Engineering cast

aluminum HEXX Hub

(US Patent No. D605,184)

.

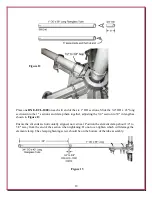

Specially designed and mechanically superior to

available home-made base plate designs, the HEXX Hub has integral V-saddles and Stainless Steel

V-Bolt hardware to firmly attach the fiberglass

spreaders in proper alignment without drilling or

crushing. The upper and lower mast mounts are

integrally cast into the hub, eliminating the need to find

separate mounting flanges, reducing assembly time,

improving mast alignment and providing a far stronger,

heavy duty attachment for the mast. For the rest of the

antenna frame, high quality stainless steel element

clamps rigidly hold the telescoping fiberglass sections at

the correct lengths without drilling holes. Exclusive DX

Engineering stainless steel element clamps with studs

provide secure attachment points for the

Five Band Stainless Steel/PTFE Rigid Feeder System

(US

Patent No. 8,669,91, US Patent No. D624,060, British Patent No. GB248003 B)

without drilling. The unique Floating

Element Wire Guides allow independent movement of the radiating wire elements and flexible

fiberglass spreaders in the wind without creating breaking stresses. These special Wire Guides are

attached to the spreaders without drilling, for a stronger, longer lasting antenna.

The DX Engineering

HEXXAGONAL BEAM Mark 2

is a directional beam antenna made with

fiberglass spreaders and wire elements that looks like a very large inverted umbrella frame. Even at

22 feet wide and approximately 5 feet tall, it has a smaller turning radius than a two element 20

meter Yagi, and offers several enhanced operating characteristics. It may be mounted at the top of a

rotatable mast or directly into a light to medium duty rotator. This antenna is fed at the top of the

center post with a single 50

Ω feedline. This top fed feedline arrangement has been tested and

proven to function better than a bottom feedpoint connection. The Mark 2 purposely excludes

poorly functioning 6 meter elements that other hex beam manufacturers have added, to preserve the

broadband hex beam antenna’s 10 and 12 meter performance.