Safety information

Service Instructions 512-211-01/532-211-01 - 00.0 - 06/2016

9

Symbols

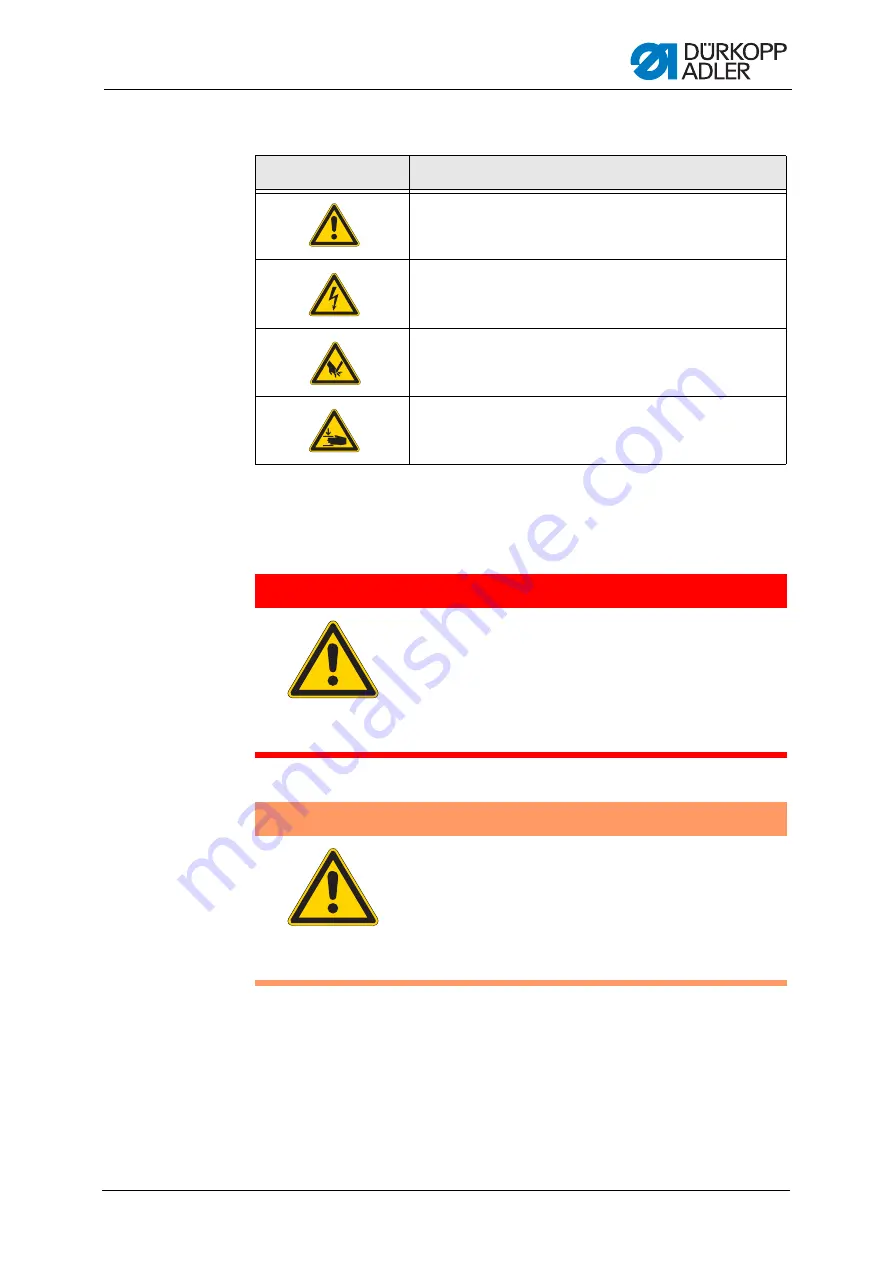

The following symbols indicate the type of risk to personnel:

Examples

Examples of the layout of the warnings in the text:

Symbol

Type of danger

General risk

Risk of electric shock

Risk of puncturing

Risk of crushing

DANGER

Type and source of risk

Consequences of non-observance

Measures for avoiding the risk

This is what a warning looks like for a hazard that

will result in serious injury or even death if not com-

plied with.

WARNING

Type and source of risk

Consequences of non-observance

Measures for avoiding the risk

This is what a warning looks like for a hazard that

could result in serious injury or even death if not

complied with.

Summary of Contents for 512-211-01

Page 6: ...Table of Contents 4 Service Instructions 512 211 01 532 211 01 00 0 06 2016...

Page 22: ...Work principles 20 Service Instructions 512 211 01 532 211 01 00 0 06 2016...

Page 72: ...Maintenance 70 Service Instructions 512 211 01 532 211 01 00 0 06 2016...

Page 76: ...Appendix 74 Service Instructions 512 211 01 532 211 01 00 0 06 2016 Circuit diagram Sheet 2...

Page 77: ...Appendix Service Instructions 512 211 01 532 211 01 00 0 06 2016 75 Circuit diagram Sheet 3...

Page 78: ...Appendix 76 Service Instructions 512 211 01 532 211 01 00 0 06 2016 Circuit diagram Sheet 4...

Page 79: ...Appendix Service Instructions 512 211 01 532 211 01 00 0 06 2016 77 Circuit diagram Sheet 5...

Page 80: ...Appendix 78 Service Instructions 512 211 01 532 211 01 00 0 06 2016...

Page 81: ......