6

HORIZONTAL INSTALLATION REQUIREMENTS

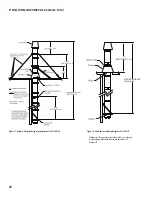

• When venting through a sidewall, terminate the system not less than 12”

(.3m) above the ground and above the snow line in geographical areas

where snow accumulates. The termination area must be kept clear of

snow and ice at all times. See

Figure 1.

• Terminate the system at least 7’ (2.1m) above a public walkway or

driveway, no less than 6’ (1.8m) from the combustion air intake of any

appliance or 3’ (.9m) from any other building opening, gas utility meter,

service regulator or the like. Less distance is permitted if specified in the

appliance’s installation instructions. It also shall terminate at least 3’ (.9M)

above any forced air inlet within 10’ (3.1m) and shall terminate at least 4’

(1.2m) below, 4’ horizontally from, or 1’ (.3m) above any door, window, or

gravity air inlet into any building as provided in the National Fuel Gas Code

ANSI Z223.1 and NFPA 54. See

Figure 1

. Proper judgment may require

greater distances depending on the side of the equipment installed or

to allow for snow drifting or falling from falling from overhead roofs or

trees. The termination should be far enough away from trees, shrubs,

or decorative items to prevent damage.

• The total horizontal vent length from the appliance flue collar to the outside

termination shall be in accordance with the appliance manufacturer’s

instructions.

MVS : Maximum Vertical Spacing between Guides/Supports

MHS: Maximum Horizontal Spacing between Guides/Supports

MDE: Maximum Distance between Elbows

H: Maximum Freestanding Height above the Roof

S: Maximum Suspended Length

SUPPORT AND GUIDE SPACING FOR MODEL DS & DSLS

Inside

diameter

MVS

MHS

MDE

H

S

Interior

Exterior

3”

10

8

12

12

10

50

4”

10

8

12

12

10

100

5”

10

8

12

12

10

100

6”

10

8

12

12

10

100

7”

10

8

12

12

10

100

8”

10

8

12

12

10

100

9”

10

8

12

12

10

100

10”

10

8

12

12

10

100

12”

10

8

12

12

10

100

14”

10

8

12

12

10

100

16”

10

8

12

12

10

100

18”

10

8

12

12

10

100

20”

10

8

12

12

10

100

22”

10

8

12

12

10

100

24”

10

8

12

12

10

100

26”

10

8

12

12

12

100

28”

10

8

12

12

12

100

30”

10

8

12

12

12

100

32”

10

8

12

12

12

100

34”

10

8

12

12

12

100

36”

10

8

12

12

12

100

Table 7: Support and Guide Spacing for Model DS & DSLS. Dimensions are in feet

SUPPORT AND GUIDE SPACING FOR MODEL DSD & DSID & DSLD

Inside

diameter

MVS

MHS

MDE

H

S

Interior

Exterior

3”

10

8

12

12

10

50

4”

10

8

12

12

10

50

5”

10

8

12

12

10

50

6”

10

8

12

12

10

50

7”

10

8

12

12

10

50

8”

10

8

12

12

10

50

9”

10

8

12

12

10

50

10”

10

8

12

12

10

50

12”

10

8

12

12

10

50

14”

10

8

12

12

10

50

16”

10

8

12

12

10

50

18”

10

8

12

12

10

50

20”

10

8

12

12

10

50

22”

10

8

12

12

10

50

24”

10

8

12

12

10

50

26”

10

8

12

12

12

50

28”

10

8

12

12

12

50

30”

10

8

12

12

12

50

32”

10

8

12

12

12

50

34”

10

8

12

12

12

50

36”

10

8

12

12

12

50

Table 8: Support and Guide Spacing for Model DSD, DSID & DSLD. Dimensions are in feet

7 ft above

public

walkways

and drives

1 ft. above doors and windows

4 ft below any

window or fresh air

inlet

1 ft. above ground or

snow line

Sidewalk

Figure 1 - Horizontal Termination Requirements

4 ft. horizontally from door

and windows