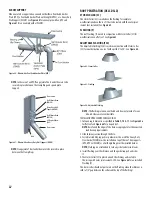

CAPS (DSLS-DSLD)

TEE CAP (TC)

The Tee Cap provides access for cleaning and inspection. Usually on

horizontal runs, the Tee Cap is used to close the unused port of any Tee and

for clean out or access purposes only. When using clean-outs, always seal

the connection to prevent leaks.

The part list includes;

lx Cap with one Handle

lx smallerV-Band (BSI)

The next Items are for the Model DSLD only:

1x Outer Casing

1x Larger V-Band (BSI)

INSTALLATION PROCEDURES

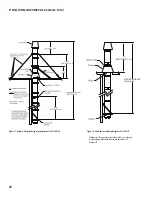

STEP 1-

(only for horizontal installation): Add Viton® Caulking over the

Viton O-ring Gasket. See

Figure 40a.

Step 2

-Use the inner V-Band (BSI) to secure the inner Cap Kit to the flange

of the 90° Tee (T90, not included) as specified in the JOINT ASSEMBLY

section.

NOTE:

Be sure the handle of the Cap faces outward as shown.

See

Figure 40a or 40b

.

Figure 40b: Step 2 for installation of the TC

DRAIN TEE CAP (DTC)

The Drain Tee Cap (DTC) is used as a drain forthe base of vertical

installations and must be connected to a suitable disposable point. It can

also be used as an access for clean outs or access purposes. (See

Figure 41

)

Same installation as a Tee Cap (TC).

ELBOWS (DSLS-DSLD)

ELBOWS (E2, El5, E30, E43, E45, E88, E90)

Elbows are used for changes in direction in horizontal or vertical

portions of a system. All elbows feature the standard joint assembly as

described in JOINT ASSEMBLY section. Elbows are used in combination to

make different angles ranging from 2° to 90° in horizontal and vertical

segments of the system.

Elbows are not designed to take bending loads and must be structurally

supported. Structural parts such as posts or beams may also be needed to

hold chimney supports in position. See ELBOW SUPPORT section.

Figure 42: 3, 15, 30, 45 and 90° Elbow

Figure 40a: Step 1 (only for Horizontal installation) Installation of the TC

Figure 41: Drain Tee Cap (DTC)

Step 3

- Mate the flange of the outer casing with the flange of the out

wall of the Tee section.

Step 4

- Secure with the bigger V-Band (BSI) by tightening the retaining

screw. See

Figure 40c.

Figure 40c: Step 3-4 for installation of the DSLD TC

25

Step 9

-Slide down the retaining band on the double flanged sleeve to

mate their flanges and tighten the retaining collar.

Step 10

-Then install the other V-band (BSI) over these flanges (like

regular joint assembly). See

Figure 38

.