32

Fix:

To fix this error, you must first power off the plotter, turn the plotter back on, wait for

the display on the plotter to load, then press the number “2” as instructed on the plotter

to complete the set-up.

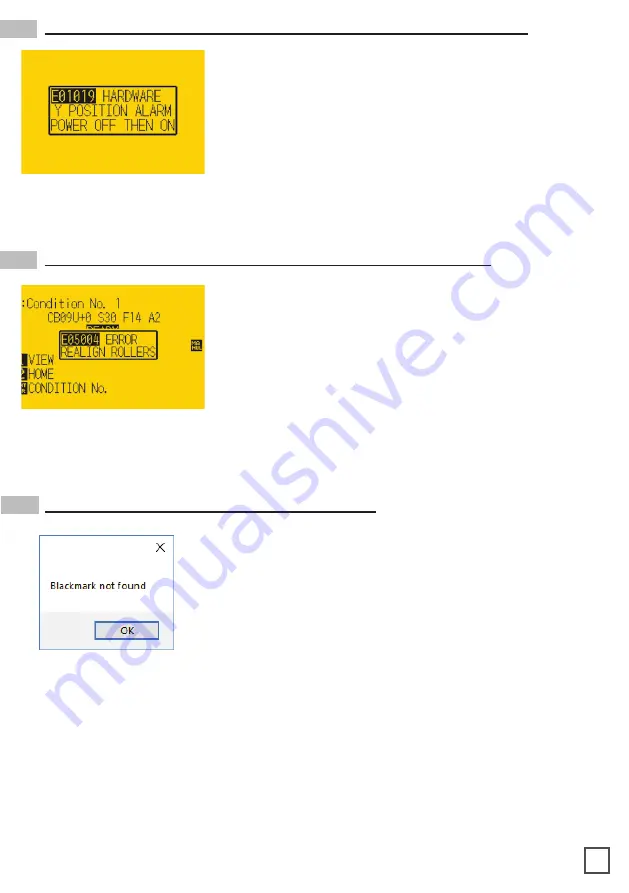

Plotter error “E01019 Hardware Y Position Alarm Power off then on”

Fix:

Before feeding the material through the plotter (While the rear lever is in the down

position) be sure that the pinch rollers are aligned properly with the plotter’s grips.

Plotter error “E05004 Hardware Realign Push Rollers Confirm”

Problem:

The plotter displays an error

“E01019 Hardware

Y Position Alarm Power off then on”.

Cause:

This error occurs when the blade tray was moved

from side to side by the user after loading the media onto

the plotter and with the rear plotter lever in the up position.

Problem:

The plotter displays an error

“E05004 Hardware

Realign Push Rollers Confirm”

Cause:

This error occurs when the pinch rollers are not

aligned properly with the plotter’s grips.

the arrows points labeled on the front and back of the plotter; the plotter’s camera is not

positioned correctly; and the plotter’s camera is picking up too much exposure from the

sunlight or another light source.

Fix:

To fix this, before you start any job in

Virgo CM

be sure to always do the following;

check and make sure the media has a black-mark printed on it to begin with; manually

aligned the media with the arrows points labeled on the front and back of the plotter

(This

is done with the plotter’s rear handle in the down position)

; make sure to position the

plotter’s camera over the blackmark in order to centered marker as much as possible on

the software camera preview.

Cutting Manager error “Black-mark not found”

Problem:

After starting a job in

Virgo CM

, you get an error

“Black-mark not found”.

Cause:

This problem occurs when after you start the job and

the software can’t detect the black-mark on the media.

The reason for this could be the following; the media is

missing a marker to begin with; the media is not aligned with