RS4203 Manual

Chapter 14 – Maintenance Guide

Rev 32, 01/11/13

Copyright © 2013, Tipper Tie, Inc., All rights reserved

94

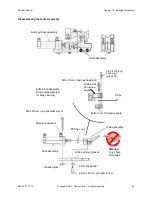

14.8.3 Grease working surfaces

___ Apply grease to all external working surfaces of the voider main shaft and drive shafts.

Also grease the voider plates and exposed shaft surfaces of the skin brake shuttle cylinder.

___ Ensure sufficient grease was used in the assembly of the horn and rotor assembly.

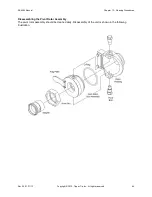

14.8.4 Inspect skin brake inserts

___ Inspect skin brake inserts inside skin brake housing for wear or damage. Replace if necessary.

Note: Depending on application, inserts can be soaked in USDA-approved mineral oil to increase

their longevity and improve their performance. Grease can also be applied to the face of the insert,

and mating seat of the housing in order to improve their adjustability.

14.8.5 Inspect conveyor

___ Inspect belt condition

___ Check to ensure that all fasteners are tight.

___ Move the conveyor chain or belt drive and the idler rollers to ensure they roll smoothly and freely.

14.8.6 Inspect voider assembly

___ Inspect the voider and skin brake assembly for any loose parts.

___ Inspect conveyor belt and bearings for excessive wear and defects.

___ Check the trip paddle for loose parts, and proper functioning.

___ Connect conveyor to the voider assembly, and apply tension to the conveyor belt.

14.8.7 Inspect clipper

___ Inspect the clipper for loose parts, particularity the lower assembly and cylinder head connections.

___ Check clip pushers and clip rails for loose parts.

14.8.8 Inspect for safety

Reactivate the machine by applying both air and electrical power to the machine.

___ Inspect and close each guard, and ensure proper powering up of machine by pressing and resetting

both Emergency Stop buttons.