RS4203 Manual

Chapter 14 – Maintenance Guide

Rev 32, 01/11/13

Copyright © 2013, Tipper Tie, Inc., All rights reserved

86

14.2 Maintenance Precautions

After performing any service or maintenance, before returning the machine to operation, always check for

and tighten any loose screws, bolts, nuts, connectors and hoses. Inspect all safety components. Closely

follow all safety warnings and notes to avoid serious injury and potential damage to the machine.

Safety Note

: Push an Emergency Stop (E-Stop) button to immediately terminate all machine functions.

Warning

: While operating or servicing the clipper, if a clip or other obstruction jams in

the die area, do not attempt to cycle the machine again until the jam is cleared. Turn off

and lock-out the air supply before attempting to remove the obstruction. Then, carefully

remove the clip or obstruction to avoid damaging the clipper.

Warning

: Do not attempt to add oil to the lubricator while the clipper is under pressure.

Disconnect the air supply at the quick disconnect, which will purge the air pressure from

the system. Lock-out the clipper.

Caution

: It is especially important that you carefully and frequently inspect the clipper for worn parts.

Check the die support channel and punch assembly, the die and die pocket area of the die support, the

clip pusher assembly and the knife assembly. Always replace worn parts as necessary.

14.3 Moisture and Corrosion Control

This section describes procedures for controlling moisture and corrosion.

Moisture Control

To control moisture that can accumulate in the electrical and pneumatic control boxes, in the operator

interface touchscreen box and in the remote pushbutton box, desiccant bags are included in each of the

boxes. The usable life of the desiccant bags can vary depending on operating conditions in the facility.

The desiccant bags should be replaced if there is any sign of moisture or at least every six months.

To further control moisture accumulation, leave the electrical power turned on while the machine is not

being used. This will maintain warmth in the boxes which will help to prevent condensation.

In addition, the heater/fan assembly in the control box will continue to run. For safety, lock out the air

pressure and push in the Emergency Stop button while the machine is not in use.

Corrosion Control

A corrosion inhibitor emitter cup is attached to the wall of the electrical and pneumatic control boxes; a

corrosion inhibitor foam emitter is attached to the wall of the operator interface touchscreen box and the

remote pushbutton box. The corrosion inhibitors should be replaced annually.

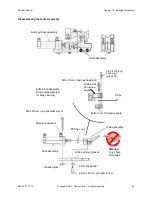

14.4 Air Prep Maintenance

The air prep assembly removes liquid and solid particles from

the air supply and controls the machine’s air pressure before it

enters the air reservoir in the frame (refer to Chapter 4 for air

prep details). The factory air supply is connected to the machine

using the quick-disconnect on the right. The incoming air is then

routed (right to left) through the air supply shutoff and lock-out

valve (with the red knob on top).