(No.HD001<Rev.001>)1-31

5.1.7.4

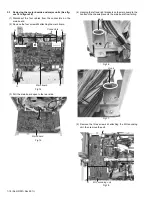

If the card is caught in the card feed roller to the

left of the retransfer heating roller

(1) Turn off the power.

(2) Check the position of the card.

(3) Attach the jog dial to the card feed roller shaft.

(4) Turn the card feed roller shaft in the anti-clockwise direc-

tion, while checking the position of the card.

• The card is discharged from the card outlet.

(5) Restore the jog dial to its original position.

(6) Install the retransfer film cassette, and close the printer

door.

(7) Turn on the power.

Go to step 5 of 5.1.7.

5.1.8 Film Search A1

• Retransfer film is broken.

Repair the retransfer film.

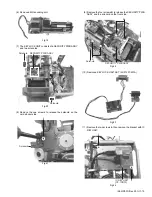

(1) Open the printer door.

(2) Press and hold down the cassette button, and remove

the retransfer film cassette. (on the left)

(3) Cut away the broken portion, and attach the unused portion

at the supply side to the other end at the take-up side using

an adhesive tape, while making sure that the joint surface

is even.

Cautions:

• If the security lock is on, deactivate it. After work is com-

plete, activate the security lock again.

• Stand the cassette on a flat surface as illustrated in the dia-

gram.

Avoid doing so on the floor as dust attached to it may cause

printing errors.

• Do not touch the retransfer face (the side that faces outward

when installed) with your hand. Touching it may cause print-

ing errors. Put on the supplied gloves when handling the re-

transfer film.

• The cassette is heavy when the retransfer film is loaded. To

prevent the cassette from dropping during handling, make

sure to hold it with both hands.

• When installing a used retransfer film, align the unused side

of the film with the arrow indicated on the label of the cas-

sette. Improper alignment may result in errors, or the print

may turn out light.

• Do not perform any work on the printer door. Do not place

heavy objects or apply load on the printer. Doing so may

damage it.

• During replacement, clean the four bobbin holders on the

printer. If burrs produced by friction with the bobbins are at-

tached to the bobbin holders, they may fall onto the card, ink

ribbon, or retransfer film, causing printing errors.

Cautions:

• Do not discard the used retransfer film at the take-up side.

Film Serch

A1

Summary of Contents for XID 8300

Page 1: ...No HD001 Rev 001 2010 10 SERVICE MANUAL CARD PRINTER XID8300 XID8300 DS XID8300C XID8300C DS ...

Page 46: ......

Page 56: ......