6. FPG TOOLS

Page 81

© 2007 DH Instruments, a Fluke Company

Purging consists of opening a valve that exchanges gas in the lubricating volume

for a fixed amount of time. The valve is then closed for a fixed amount of time to

allow for stability. The change in humidity between the beginning and end of the cycle

is used to determine if the purge process should be repeated. Purging is repeated

until the humidity criterion is met or the

<Operation Abort>

function is used.

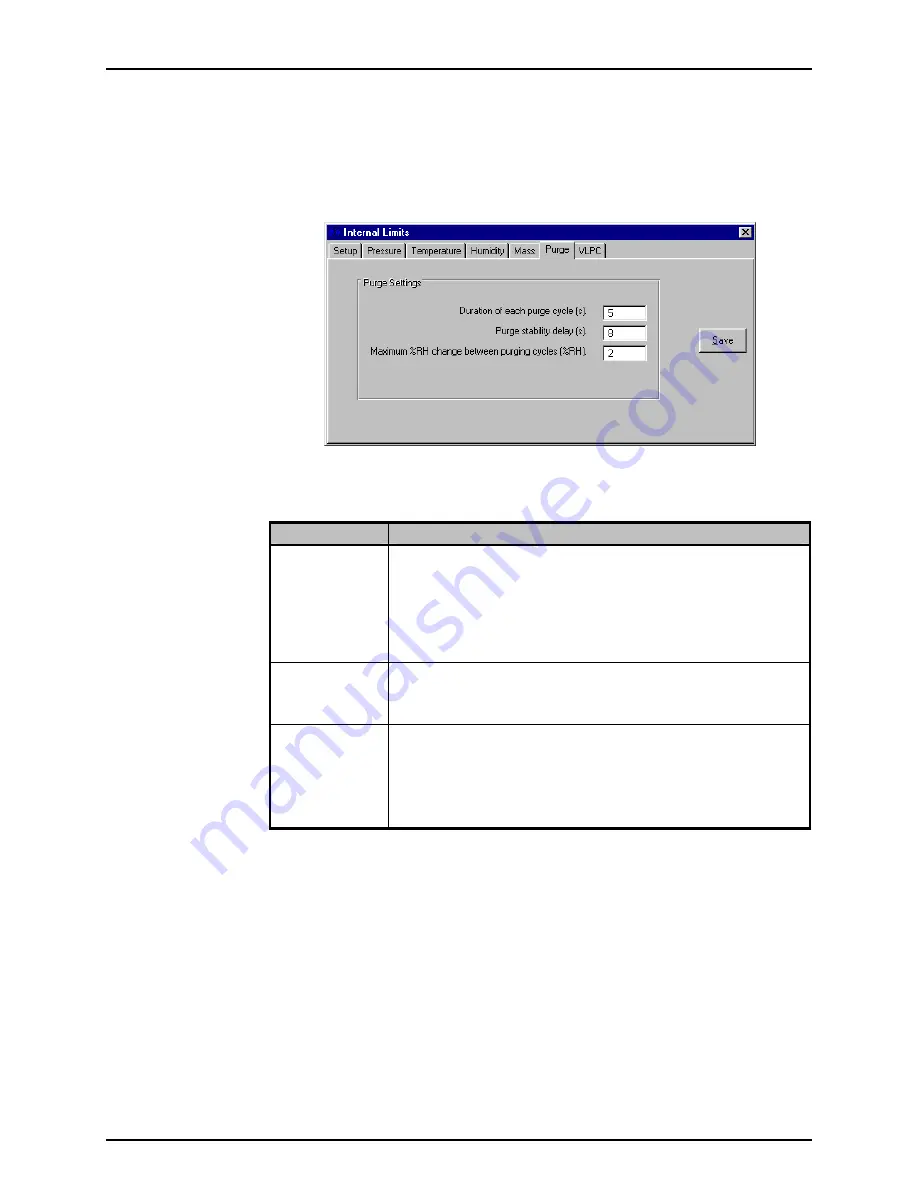

Figure 38. <Internal Limits> <Purge>

Table 25. <Internal Limits> <Purge>

Options

LABEL

DESCRIPTION

Duration of each

purge cycle

(numeric entry field)

Enter a value that specifies how long gas will be removed from the

lubricating volume. In gauge mode, if the limit is sufficiently long, the

lubrication pressure will approach ATM. In absolute mode, the lubrication

pressure will slowly approach vacuum. Completely removing all gas in the

lubricating volume is the goal of purging only when the gas has been

changed. Typically, the goal is to obtain a stable humidity value in the

proper range. Removing a small amount of gas several times is all that is

needed to accomplish this task.

Purge stability

delay

(numeric entry field)

The time in seconds that FPG Tools should wait prior to comparing the

before and after humidity values. If the time is not long enough to allow the

FPG regulators to re-fill the volume, the purging process will take longer

than necessary or may not obtain proper humidity conditions.

Maximum %RH

change between

purging cycles

(numeric entry field)

Maximum change between the humidity at the beginning of the purge and

the humidity after the stability test. If the humidity change exceeds this limit,

the purge cycle is repeated. With each successive purge cycle, the change

in humidity should decrease because the volume should approach the

target equilibrium humidity. Using a value too small for this field will keep

the FPG in a continuous purge loop. On the other hand if the value is too

large, the volume will not be properly purged.

6.6.4.7

<VLPC>

The minimum and default control limits of the VLPC are defined on this tab.

The active control settings used to determine a “Ready” condition are defined by

the active test sequence or the current setup in the

<Settings>

(see Section

6.6.1) option. When the hold setting is set too small, the limits setup on this tab

determine the actual criterion imposed on the pressure “Ready/Not

Ready” indication. Each time a new pressure range is set, the default hold limits

specified on this tab are set.

There are separate default values for each gauge and absolute pressure range.

The available ranges and the corresponding percent of range hold limits are

available only after

[Run], [Run Monitor]

is used and the VLPC is enabled. The

available ranges are dependent on the specific setup of the VLPC.