Accessories - Pneumatic Autodrain

Maximum working pressure of 200 psi (13.8 Bar).

Minimum working pressure of 30 psi (2.1 Bar).

Anodized aluminum body.

Stainless steel piston, spring, ball, screens, and

reservoir.

Buna seals and teflon ring.

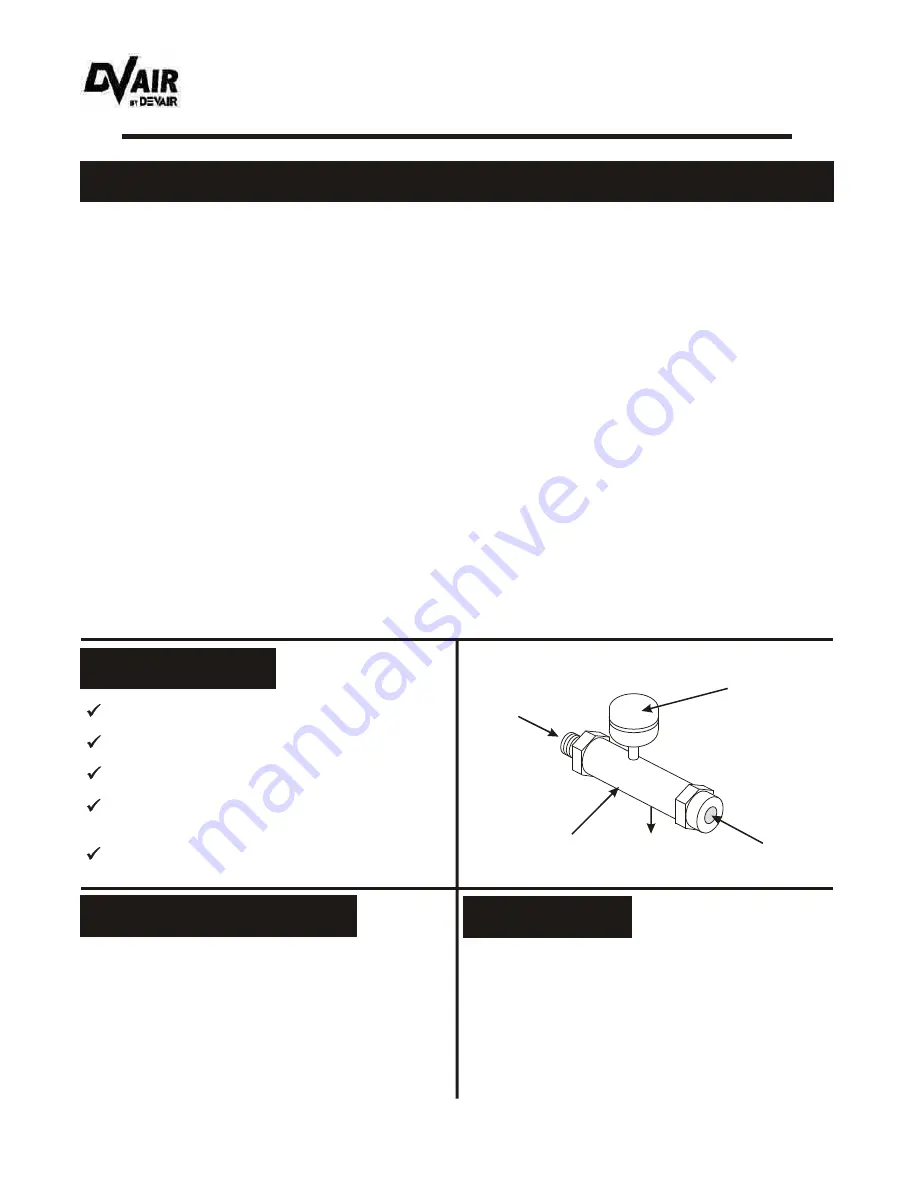

AutoDrain Assembly

Drain

Port

Reservoir

Moisture

from Tank

Pilot Signal

from

Unloader

1.

Maintenance/service work must only be done when

the Autodrain is not under pressure.

2.

Ensure the Autodrain is not subjected to

temperatures below freezing.

3.

Suitable arrangements must be made to ensure the

moisture is properly contained once evacuated from

the AutoDrain.

The ‘AD-9400’ Autodrain is designed to drain moisture from the Compressor Unit each time the Unit

reaches maximum pressure and shuts off. As shown, the Unit receives its ‘pilot’ signal from the

Compressor Unloader, being tied into the Unloader Line by means of a Compression Tee.

All that is required for the automatic operation of the Autodrain is an intermittent air source like that

obtained by tapping into the Compressor Unloader Line.

A) The pilot signal (or air pressure) on the Unloader Line forces an internal Piston past the Drain Port,

sealing the internal Chamber from atmosphere.

B) As the Piston is forced forward, the internal Stainless Steel Ball Valve is opened, permitting

condensate and oil to be forced up into the Reservoir.

C) The air in the top of the Reservoir is compressed to system pressure.

D) As the pilot signal is returned to zero, the internal Piston returns, closing the system from the

atmosphere.

E) When the Piston reaches it’s original position, the Drain Port is opened, allowing the condensate to

escape.

As noted, suitable arrangements must be made to contain the condensate that is expelled from the

Autodrain. As the condensate may contain traces of oil, it must be disposed of accordingly.

What is the purpose of the ‘AD-9400’ Autodrain?

Specifications:

Important Information:

Maintenance:

The Trap Mesh and Flat Mesh in the AutoDrain must be

cleaned periodically in order to ensure the Unit works

properly, and does so for a long period of time.

Devair offers a Repair Kit for the Unit, namely an ‘RK-AD-

9400’. The Kit includes a Flat Screen, Trap Screen, ‘O’

Ring, Piston and Seal Assembly, and an End Cap

Gasket.

- 13 -

HDI-01

Mar ‘07

Distributed by: CENTRAIR Air Systems & Supplies, 68 Hooper Rd., Unit 5, Barrie, ON L4N 8Z9

Phone: 705-722-5747 Fax: 705-722-5458 [email protected] www.centrair.ca

All manuals and user guides at all-guides.com