Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

16

Document No. 896 623

3.3.2

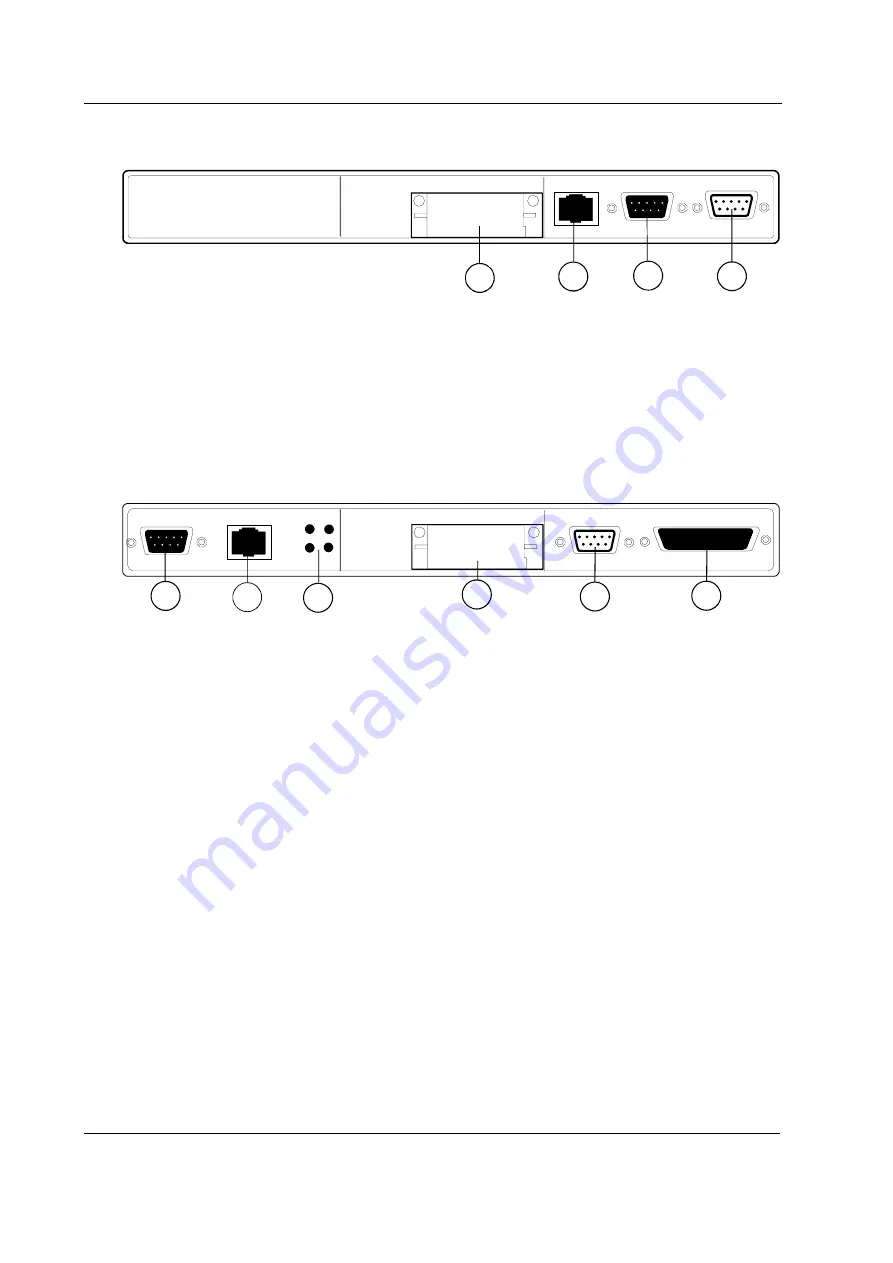

Rear panel connectors

2

3

4

1

Figure 8

Rear Panel with Memory, CPU and UPINET Boards

(1)

Software Cartridge, on CPU board, B-CPU2 or B-CPU3,

or Software Card drive and lid for back plate on B-CMCPU4,

connector on B-CMCPU4 is reserved for future use (not in figure).

(2)

Network connector

(3)

Network identification plug connector

(4)

Serial communication connector

1

2

3

4

5

6

Figure 9

Rear Panel with NET, CPU and UPI Boards. NET and UPI Boards can be

replaced by UPINET board.

(1)

Network identification plug connector

(2)

Network connector

(3)

Ethernet status LEDs

(4)

Software Cartridge, on CPU board, B-CPU2 or B-CPU3,

or Software Card drive and lid for back plate on B-CMCPU4,

connector on B-CMCPU4 is reserved for future use (not in figure).

(5)

Serial communication connector

(6)

Parallel printer port, analogue & digital input/output connector

CAUTION

Turn the power off before making any rear panel connections.

NOTE

: Your monitor configuration may not include all circuit boards listed above.