READING FEATURES

93

9

3.

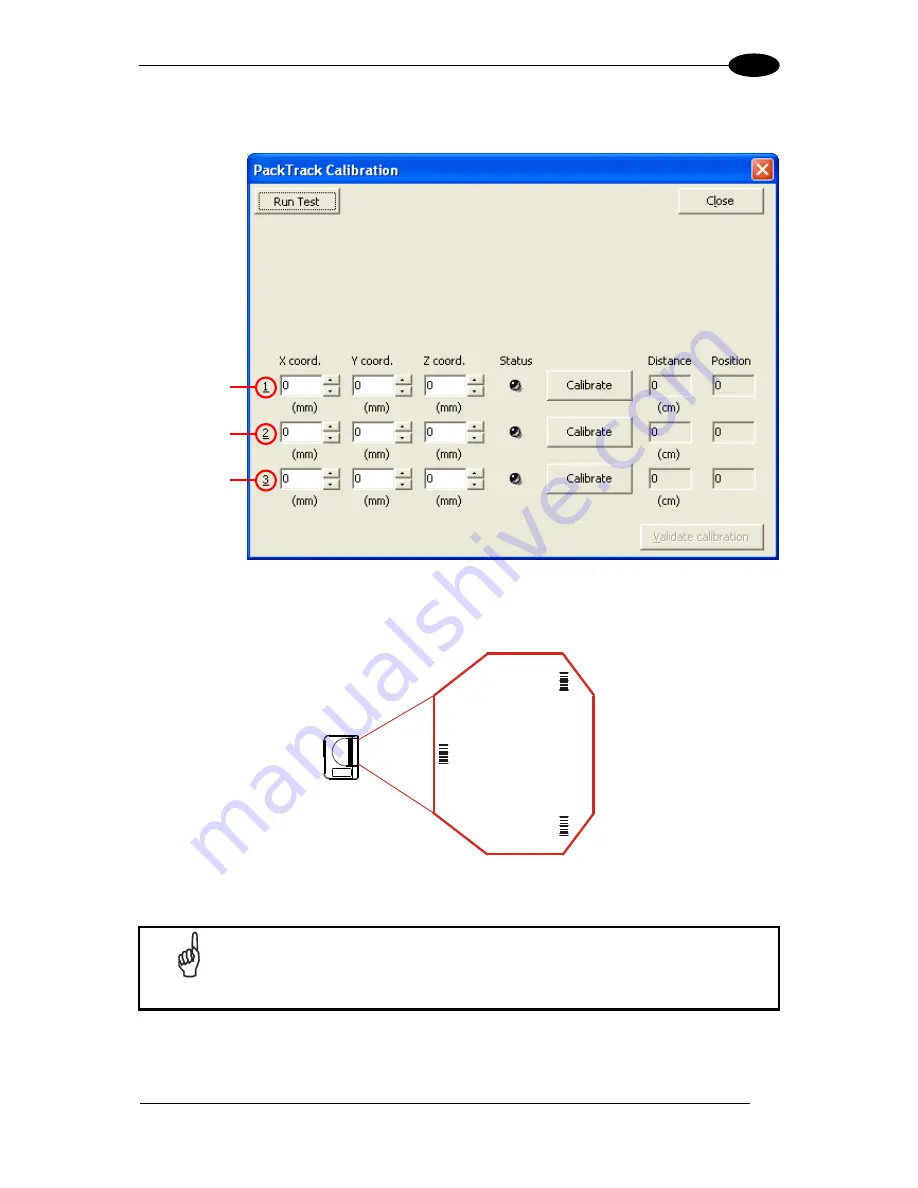

By selecting the “PackTrack Calibration” option a further dialog box appears allowing to

start calibration:

Figure 100

– Performing the PackTrack™ Calibration

4. Place the code at one of the desired positions on the scan line (i.e. Position 1).

5. Measure the X, Y and Z coordinates relative to the

center

of the code and enter them

into the corresponding edit boxes.

NOTE

In the vast majority of systems the x and z data are not necessary. For

these cases set x = 0, z= 0 during the calibration procedure.

6. Press the Calibrate button for Position 1 to start the calibration.

Position 1

Position 2

Position 3

Position 1

Position 2

Position 3

Summary of Contents for DS8100A

Page 1: ...DS8100A Reference Manual ...

Page 141: ...www datalogic com ...