Disconnecting wires from the control terminals

1.

To open the contact, insert a small screwdriver

into the slot between the terminal holes and

push the screwdriver inward.

2.

Pull gently on the wire to free it from the control

terminal contact.

See

chapter 10.5 Cable Specifications

for control terminal

wiring sizes and

chapter 8 Wiring Configuration Examples

for

typical control wiring connections.

5.9.4 Enabling Motor Operation

(Terminal 27)

A jumper wire is required between terminal 12 (or 13) and

terminal 27 for the drive to operate when using factory

default programming values.

•

Digital input terminal 27 is designed to receive

24 V DC external interlock command.

•

When no interlock device is used, wire a jumper

between control terminal 12 (recommended) or

13 to terminal 27. This wire provides an internal

24 V signal on terminal 27.

•

When the status line at the bottom of the LCP

reads

AUTO REMOTE COAST

, the unit is ready to

operate, but is missing an input signal on

terminal 27.

•

When factory-installed optional equipment is

wired to terminal 27, do not remove that wiring.

NOTICE

The drive cannot operate without a signal on terminal

27, unless terminal 27 is reprogrammed using

parameter 5-12 Terminal 27 Digital Input

.

5.9.5 Configuring RS485 Serial

Communication

RS485 is a 2-wire bus interface compatible with multi-drop

network topology, and it contains the following features:

•

Either Danfoss FC or Modbus RTU communication

protocol, which are internal to the drive, can be

used.

•

Functions can be programmed remotely using

the protocol software and RS485 connection or in

parameter group 8-** Communications and

Options

.

•

Selecting a specific communication protocol

changes various default parameter settings to

match the specifications of the protocol, making

more protocol-specific parameters available.

•

Option cards for the drive are available to provide

more communication protocols. See the option

card documentation for installation and operation

instructions.

•

A switch (BUS TER) is provided on the control

card for bus termination resistance. See

For basic serial communication set-up, perform the

following steps:

1.

Connect RS485 serial communication wiring to

terminals (+)68 and (-)69.

1a

Use shielded serial communication cable

(recommended).

1b

See

chapter 5.4 Connecting to Ground

for

proper grounding.

2.

Select the following parameter settings:

2a

Protocol type in

parameter 8-30 Protocol

.

2b

Drive address in

parameter 8-31 Address

.

2c

Baud rate in

parameter 8-32 Baud Rate

.

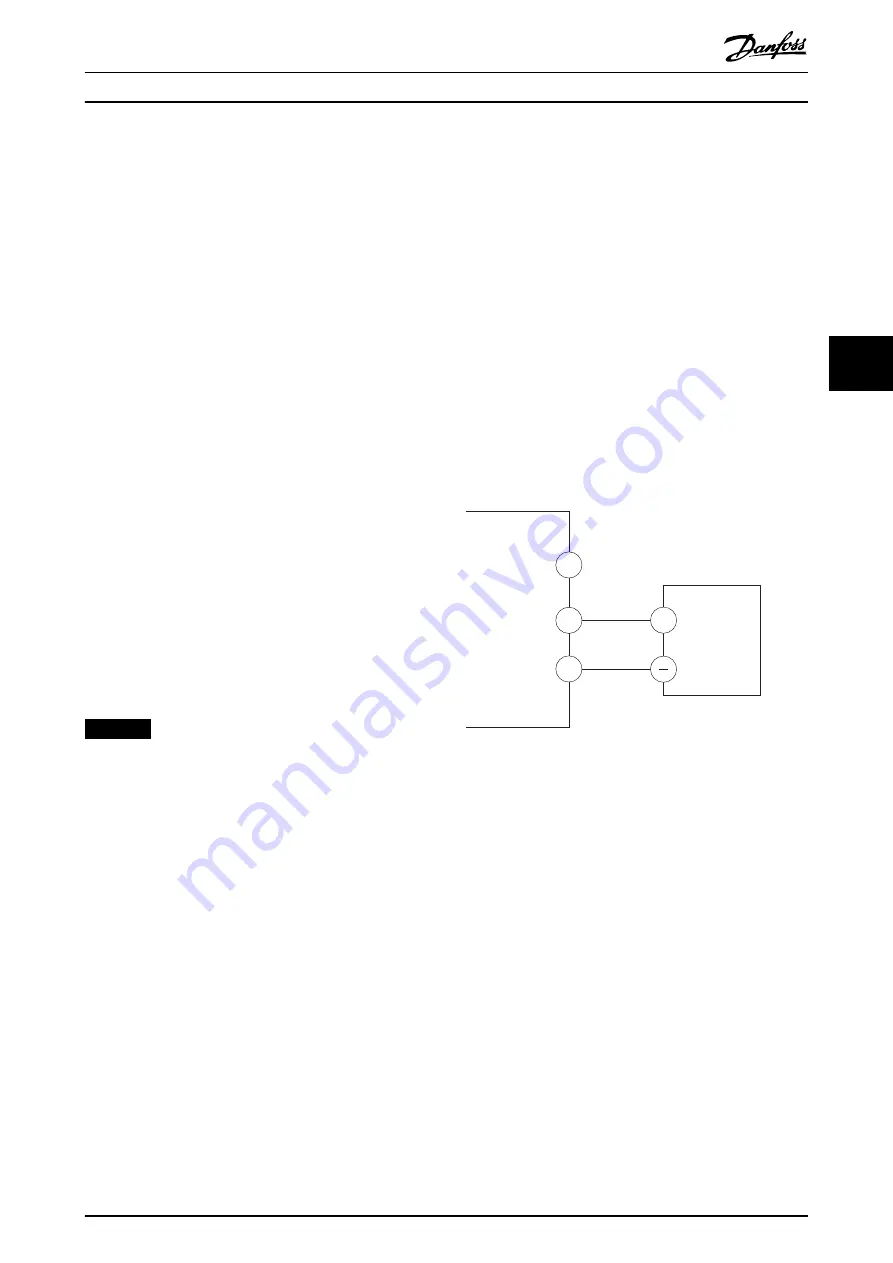

61

68

69

+

130BB489.10

RS485

Illustration 5.39 Serial Communication Wiring Diagram

5.9.6 Wiring Safe Torque Off (STO)

The Safe Torque Off (STO) function is a component in a

safety control system. STO prevents the unit from

generating the voltage required to rotate the motor.

To run STO, more wiring for the drive is required. Refer to

Safe Torque Off Operating Guide

for further information.

5.9.7 Wiring the Space Heater

The space heater is an option used to prevent conden-

sation from forming inside the enclosure when the unit is

turned off. It is designed to be field wired and controlled

by an external system.

Specifications

•

Nominal voltage: 100–240

•

Wire size: 12–24 AWG

Electrical Installation

Operating Guide

MG34U502

Danfoss A/S © 09/2018 All rights reserved.

65

5

5

Summary of Contents for VLT AutomationDrive FC 302

Page 2: ......