18

|

Piping installation

Installer and user reference guide

108

RYMA5+RXYA8~20A7Y1B

VRV 5 heat pump

4P749918-1 – 2023.12

18.2.8 To braze the pipe end

NOTICE

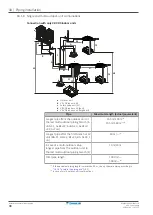

Precautions when connecting field piping. Add brazing material as shown in the

figure.

1

1

1

1

2

2

≤Ø25.4

>Ø25.4

▪

When brazing, blow through with nitrogen to prevent creation of large quantities

of oxidised film on the inside of the piping. This film adversely affects valves and

compressors in the refrigerating system and prevents proper operation.

▪

Set the nitrogen pressure to 20 kPa (0.2 bar) (just enough so it can be felt on the

skin) with a pressure-reducing valve.

a

b

c

d

e

f

f

a

Refrigerant piping

b

Part to be brazed

c

Taping

d

Manual valve

e

Pressure-reducing valve

f

Nitrogen

▪

Do NOT use anti-oxidants when brazing pipe joints. Residue can clog pipes and

break equipment.

▪

Do NOT use flux when brazing copper-to-copper refrigerant piping. Use phosphor

copper brazing filler alloy (BCuP), which does NOT require flux.

Flux has an extremely harmful influence on refrigerant piping systems. For

instance, if chlorine based flux is used, it will cause pipe corrosion or, in

particular, if the flux contains fluorine, it will deteriorate the refrigerant oil.

▪

ALWAYS protect the surrounding surfaces (e.g. insulation foam) from heat when

brazing.

18.2.9 To connect the refrigerant piping to the outdoor unit

INFORMATION

All local inter unit piping are field supplied except the accessory pipes.

Summary of Contents for VRV 5 RXYA8A7Y1B

Page 197: ......

Page 198: ......

Page 199: ......

Page 200: ...4P749918 1 2023 12 Copyright 2023 Daikin Verantwortung f r Energie und Umwelt...