English

11

•

When two wires are connected to a single terminal, connect them so

that the rear sides of the crimp contacts face each other. Also, make

sure the thinner wire is on top, securing the two wires simultaneously

to the resin hook using the included clamp (1).

7-6 Procedure for Wiring Inside Units

•

Referring to figure 23, secure and wire the power and transmission

wiring using the included clamp (1), (2), and (3).

•

Wire so that the ground wiring does not come into contact with the

compressor lead wiring.

If they touch, this may have an adverse effect on other devices.

•

The transmission wiring must be at least 2 in. away from the power wiring.

•

Make sure all wiring do not contact to the pipes (hatching parts in the

figure 23).

(Refer to figure 23)

1.

Secure to the hook of column support using the accessory

calmp (1).

2.

Electric conduit

3.

When routing out the power/ground wires from the left side.

4.

When routing out the transmission wiring from the opening

for piping.

5.

When routing out the power/ground wires from the front.

6.

Clear over 2 in..

7.

When routing out the transmission wiring from the knockout

hole.

8.

When routing out the power/ground wires from the right side.

9.

Power wiring

10.

Ground wire

11.

Transmission wiring

12.

When wiring, exercise sufficient caution not to detach the

acoustic insulators from the compressor.

13.

Secure to the back side of the support beam using the

accessory clamp (1).

14.

Retain to the back of the column support with the accessory

clamp (2).

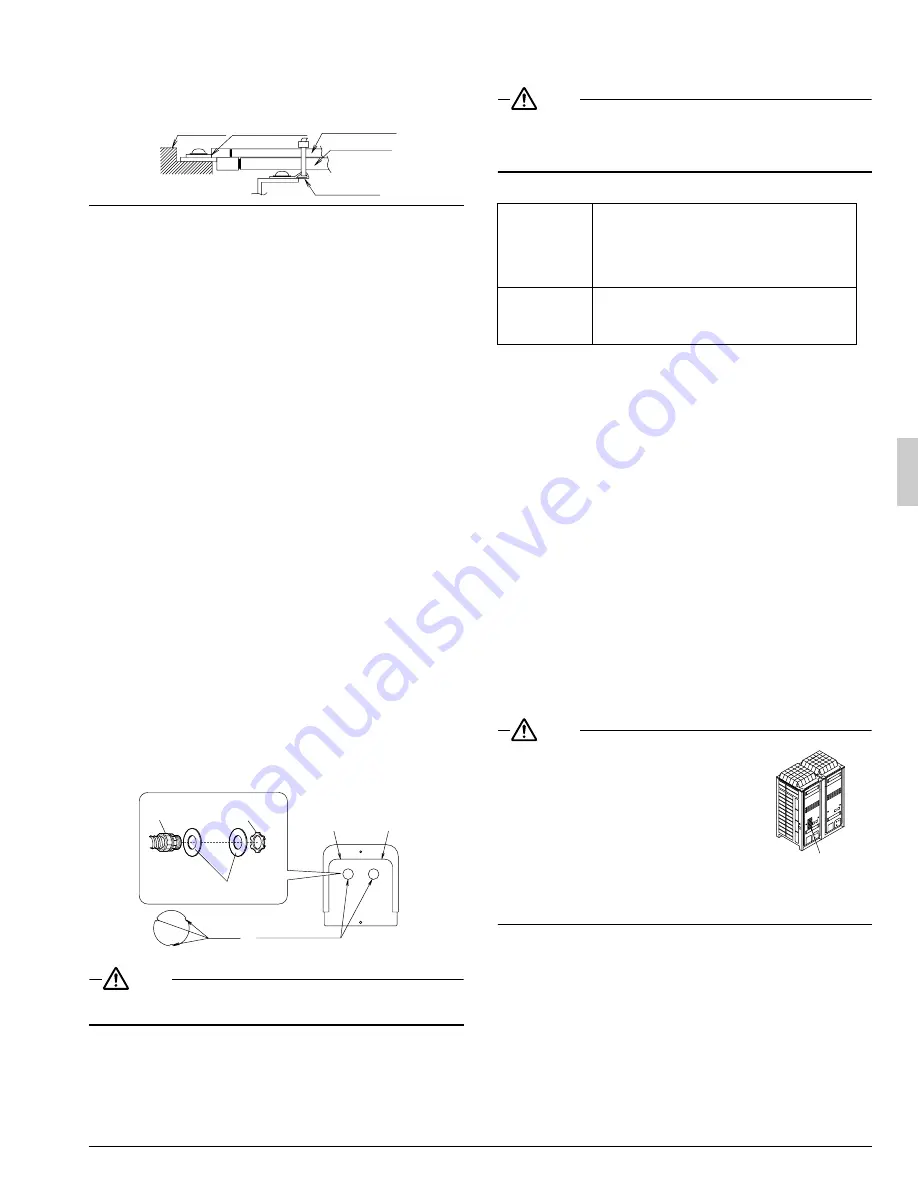

Precautions when knocking out knockout holes

•

To punch out a knockout hole, hit it with a hammer.

•

Open an appropriate hole as needed.

•

After knocking out the holes trim off the burr, then we recommend

you to paint the edges and areas around the edges using the repair

paint to prevent rusting.

•

Power line : Open a knockout hole as shown at left and connect

it using a conduit.

•

Transmission line : Connect it using a conduit in the knockout hole

on the right.

NOTE

•

After wiring work is completed, check to make sure there are no loose

connections among the electrical parts in the EL.COMPO.BOX.

8.

AIR TIGHT TEST AND VACUUM DRYING

•

After finished piping work, carry out air tight test and vacuum drying.

NOTE

•

Always use nitrogen gas for the airtightness test.

•

Absolutely do not open the shutoff valve until the main power ciruit

insulation measurement has been completed. (measuring after the

shutoff valve is opened will cause the insulation value to drop.)

<Needed tools>

<The system for air tight test and vacuum drying>

•

Referring to figure 24, connect a nitrogen tank, refrigerant tank, and

a vacuum pump to the outside unit.

The refrigerant tank and the charge hose connection to refrigerant

charge port or the valve A in figure 24 are needed in

“11. ADDI-

TIONAL REFRIGERANT CHARGE AND CHECK OPERATION”

.

(Refer to figure 24)

1.

Gauge manifold

2.

Nitrogen

3.

Measuring device

4.

R410A tank (with siphon)

5.

Vacuum pump

6.

Charge hose

7.

Refrigerant charge port

8.

HP/LP gas pipe shutoff valve

9.

Suction gas pipe shutoff valve

10.

Liquid pipe shutoff valve

11.

Valve A

12.

Valve B

13.

Valve C

14.

Outside unit

15.

To BS (or indoor) unit

16.

Shutoff valve

17.

Service port

18.

Field piping

19.

Gas flow

NOTE

•

The air-tightness test and vacuum drying

should be done using the service ports of

equalizer pipe, HP/LP gas pipe, suction gas

pipe and liquid pipe shutoff valve.

See the [R410A] Label attached to the front

plate of the outside unit for details on the loca-

tion of the service port (see figure at right)

•

See

[Shutoff valve operation procedure]

in

“11-1 Before working”

for details on handling

the shutoff valve.

•

The refrigerant charge port is connected to unit pipe.

When shipped, the unit contains the refrigerant, so use caution when

attaching the charge hose.

<Air tight test>

Pressurize the liquid pipe, suction gas pipe, HP/LP gas pipe and

equalizer pipe from the service ports of each shutoff valve to 550 psi

(do not pressurize more than 550 psi). If the pressure does not drop

within 24 hours, the system passes the test.

If there is a pressure drop, check for leaks, make repairs and perform

the airtight test again.

Terminal

block

Crip style

terminal

Wire : narrow

Wire : thick

Resin hook

Burr

Knockout hole

Left side

Right side

Conduit

(field supply)

Lock nut

(field supply)

Conduit mounting plate

(accessory)

Gauge manifold

Charge hose

valve

•

To prevent entry of any impurities and insure

sufficient pressure resistance, always use the

special tools dedicated for R410A.

•

Use charge hose that have pushing stick for

connecting to service port of shutoff valves or

refrigerant charge port.

Vacuum pump

•

The vacuum pump for vacuum drying should

be able to lower the pressure to –14.6 psi.

•

Take care the pump oil never flow backward

into the refrigerant pipe during the pump stops.

[R410A] Label