16 Maintenance

Installer and user reference guide

34

BRK+S

Wired remote controller

4P513689-1A – 2018.03

Precautions when performing a test operation

CAUTION

Before starting up the system, make sure:

▪ The indoor and outdoor unit wiring is completed.

▪ The switch box covers of the indoor and outdoor units

are closed.

NOTICE

Be sure to turn on the power 6 hours before operation in

order to have power running to the crankcase heater and

to protect the compressor.

INFORMATION

After the installation of the refrigerant piping, drain piping,

and electrical wiring, make sure to clean the inside of the

indoor unit, as well as the decoration panel.

To perform a test operation

1

Confirm that the indoor unit gas and liquid stop valves are open.

INFORMATION

It is possible that the pressure inside the refrigerant circuit

does not rise, despite the opened stop valve. This can be

due to the expansion valve (or the like) blocking the

refrigerant, and does not obstruct the test run.

2

Open the Madoka Assistant app.

3

Navigate to the operation screen of the controller that is

connected to the indoor unit(s) on which you want to perform a

test run.

4

In the operation screen, set the operation mode to Cooling.

5

Go to the "Unit settings" menu (upper right corner of the

operation screen).

Result:

You are in the "Unit settings" menu.

6

In the "Maintenance field", tap "Test operation".

Result:

You are in the "Test operation" menu.

7

Tap "Start test operation".

Result:

The indoor unit(s) enter test operation mode, during

which normal operation is not possible.

8

Return to the operation screen.

9

Tap "Vertical airflow direction".

10

Tap "Fixed".

11

Cycle through the five fixed airflow directions, and confirm if the

indoor unit flaps behave correspondingly.

12

Return to the "Test operation" menu.

13

Tap "Stop test operation".

Result:

The indoor units leave test operation mode. Normal

operation is possible again.

14

Go to

and confirm if the indoor unit(s)

behave according to the information set out there.

15

Check the error history. If required, solve the cause of the errors

and perform the test operation again.

INFORMATION

The test operation finishes after 30 minutes.

16

Maintenance

16.1

Maintenance safety precautions

WARNING

Before carrying out any maintenance or repair activities,

stop system operation with the controller, and turn off the

power supply circuit breaker.

Possible consequence:

electric shock or injury.

NOTICE

To clean the controller, do NOT use organic solvents, such

as paint thinner.

Possible consequence:

damage, electric

shock, or fire.

WARNING

Do

not

wash

the

remote

controller.

Possible

consequence:

electric leakage, electric shock, or fire.

INFORMATION

When the dirt on the surface cannot be removed easily

while cleaning the controller, soak the cloth in neutral

detergent diluted with water, squeeze the cloth tightly, and

clean the surface. Afterwards, wipe dry with a dry cloth.

16.2

About maintenance

When the indoor unit needs to be maintained, the controller will

display

on the home screen, and confront you with a warning

screen as soon as you try to enter the main menu. Perform the

required maintenance, and then remove the warning screen.

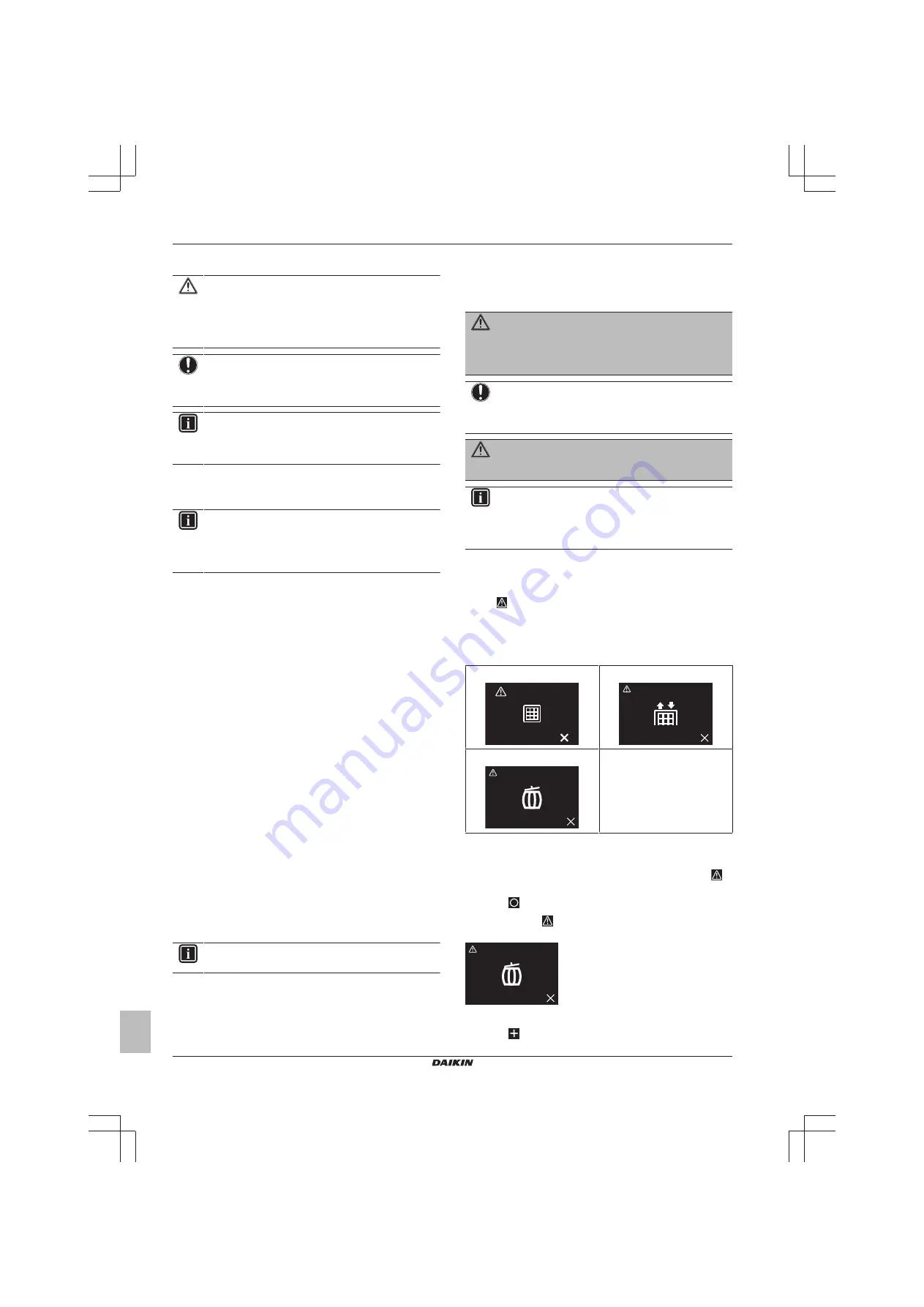

The following warning screens are related to indoor unit

maintenance:

Time to clean filter

Time to replace filter

Time to empty dust collector

—

16.3

To remove a warning screen

Prerequisite:

The controller displays the home screen, and

is

visible, indicating error or maintenance.

1

Press

to enter the main menu.

Result:

Since

is visible, you are confronted with a warning

screen, e.g.

2

Solve the cause of the warning screen.

3

Press

to remove the warning screen.