R E V I E W D R A F T — C I S C O C O N F I D E N T I A L

3-13

Cisco 7500 Series Installation and Configuration Guide

OL-5008-03 B0

Chapter 3 Installing a Cisco 7500 Series Router

Installing the Cisco 7507 and Cisco 7507-MX

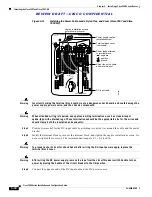

Figure 3-8

Removing

and Replacing Processor Modules—

(

Cisco 7507 and Cisco 7507-MX)

Note

The Cisco 7507 or Cisco 7507-MX installation must comply with all applicable codes and is approved

for use with copper conductors only. The ground bond fastening hardware should be of compatible

material and preclude loosening, deterioration, and electrochemical corrosion of hardware and joined

material. Attachment of the chassis ground to the central office or other interior ground system should

be made with a 6-AWG, copper ground conductor at a minimum. The Cisco 7507 and Cisco 7507-MX

chassis employ two threaded M5 chassis grounding receptacles, which are intended to be bonded directly

to the central office or other interior ground system. These receptacles are located on the rear of the

chassis. The chassis ground requires M5 screws and locking hardware, which are not included. (To

properly ground the chassis, see the

“Providing a Ground Connection for the Chassis” section on

page 3-2

.)

H2622

STOP!

on contact

Bottom ejector lever

Captive

installation

screw

Card

carrier

guide

A

B

C

Remove a module as follows:

1. Use a screwdriver to loosen the captive installation

screws (shown in A).

2. Pull the ejector levers out to release the module from the

backplane connector (shown in B). The levers should snap

into their spring retainers.

3. Grasp the module handle with one hand and place your

other hand under the carrier to support and guide the

module as you pull it out of the slot. Avoid touching the card.

4. Place the removed module in the board racks that were

provided with your packing material.

5. Install a new module or a filler (MAS-7KBLANK or MAS-

RSPBLANK) to keep dust out of the chassis and to maintain

proper airflow through the chassis.

Install a module as follows:

1. Choose a slot for the new module and ensure that there is

enough clearance to accommodate any interface equipment

that you will connect directly to its ports.

2. Use a screwdriver to loosen the captive installation screws

(shown in A) and remove the filler (or the existing module)

from the slot to be filled.

3. Hold the module handle with one hand, and place your

other hand under the carrier to support the module and guide

it into the slot. Avoid touching the card.

4. Place the back of the module in the slot and align the guide

on the carrier with the groove in the slot (shown in A).

5. Carefully slide the module into the slot until the faceplate

makes contact with the ejector levers (shown in C).

6. Use the thumb and forefinger of each hand to push the

top lever down and the bottom lever up to fully seat the

module in the backplane connector (shown in B).

7. Use a screwdriver to tighten the captive installation screws.

Card

slot