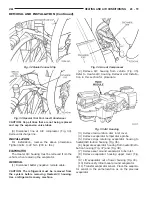

COMPRESSOR CLUTCH/COIL ASSEMBLY

The clutch assembly consists of a stationary elec-

tromagnetic coil, hub bearing pulley assembly, and

clutch plate.

The electromagnetic coil and pulley are retained on

the compressor with snap rings. The clutch plate is

mounted on the compressor shaft and secured with a

nut.

When the compressor is not operating, the pulley

free wheels on the hub bearing which is part of the

pulley. When the coil is energized the plate is mag-

netically engaged with the pulley and turns the com-

pressor shaft.

ENGINE COOLING SYSTEM REQUIREMENTS

To maintain ample temperature levels from the

heating-A/C system, the cooling system must be in

proper working order. Refer to Group 0, Lubrication

and Maintenance or Group 7, Cooling System of this

manual.

The use of a bug screen is not recommended. Any

obstructions forward of the condenser can reduce the

effectiveness of the air conditioning system.

EVAPORATOR PROBE

The evaporator probe is a temperature sensing ele-

ment located at the coldest point on the face of the

evaporator. Output from the probe is sampled by the

Body Control Module (BCM). It is used to switch the

A/C compressor clutch OFF before evaporator freeze

up occurs. The clutch is switched OFF when the

probe temperature reaches 0.94°C. (33.7°F.). It is

allowed to switch ON when the probe temperature

reaches 2.05°C. (35.7°F.).

The evaporator probe is located on the lower right

side of the evaporator housing.

EXPANSION VALVE

The expansion valve is located on the engine side

of the dash panel, near the right shock tower.

The expansion valve can fail in three different

positions (open, closed or restricted).

In an Open Position: this will result in a noisy

compressor or no cooling. The cause can be a broken

spring, broken ball or excessive moisture in the A/C

system. If the spring or ball are found to be defective,

replace the expansion valve. If excessive moisture is

found in the A/C system, recycle the refrigerant.

In a Closed Position: There will be low suction

pressure and no cooling. This may be caused by a

failed power dome or excessive moisture in the A/C

system. If the power dome on the expansion valve is

found to be defective replace the expansion valve. If

excessive moisture is found recycle the refrigerant.

A Restricted Orifice: There will be low suction

pressure and no cooling. This may be caused by

debris in the refrigerant system. If debris is believed

to be the cause, recycle the refrigerant and replace

the expansion valve and receiver/drier.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the

capacity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all connec-

tions are pressure tight. Dirt and moisture can enter

the system when it is opened for repair or replace-

ment of lines or components. The refrigerant oil will

absorb moisture readily out of the air. This moisture

will convert into acids within a closed system.

CAUTION: The system must be completely empty

before opening any fitting or connection in the

refrigeration system. Open fittings with caution

even after the system has been emptied. If any

pressure

is

noticed

as

a

fitting

is

loosened,

retighten fitting and evacuate the system again.

A good rule for the flexible hose lines is to keep

the radius of all bends at least 10 times the diame-

ter of the hose. Sharper bends will reduce the flow

of refrigerant. The flexible hose lines should be

routed so they are at least 3 inches (80 mm) from

the exhaust manifold. Inspect all flexible hose lines

to make sure they are in good condition and prop-

erly routed.

The use of correct wrenches when making con-

nections is very important. Improper wrenches or

improper use of wrenches can damage the fittings.

The internal parts of the A/C system will remain

stable as long as moisture-free refrigerant and

refrigerant oil is used. Abnormal amounts of dirt,

moisture or air can upset the chemical stability.

This may cause operational troubles or even seri-

ous damage if present in more than very small

quantities.

When opening a refrigeration system, have every-

thing you will need to repair the system ready. This

will minimize the amount of time the system must

be opened. Cap or plug all lines and fittings as

soon as they are opened. This will help prevent the

entrance of dirt and moisture. All new lines and

components should be capped or sealed until they

are ready to be used.

All tools, including the refrigerant dispensing

manifold, the manifold gauge set, and test hoses

should be kept clean and dry.

THERMAL LIMITER SWITCH

The switch is used to measure compressor surface

temperature. If compressor surface temperature is

excessive the switch will cut battery feed voltage to

24 - 4

HEATING AND AIR CONDITIONING

JA

DESCRIPTION AND OPERATION (Continued)

Summary of Contents for Stratus LHD 1997

Page 11: ......

Page 79: ......

Page 193: ......

Page 205: ......

Page 239: ......

Page 273: ......

Page 293: ......

Page 296: ...Charging System Schematic Typical JA CHARGING SYSTEM 8C 3 DIAGNOSIS AND TESTING Continued ...

Page 307: ......

Page 309: ......

Page 343: ...8D 34 IGNITION SYSTEM JA SPECIFICATIONS Continued ...

Page 377: ...8D 34 IGNITION SYSTEM JA SPECIFICATIONS Continued ...

Page 379: ......

Page 381: ......

Page 395: ......

Page 399: ......

Page 421: ......

Page 469: ......

Page 509: ......

Page 515: ......

Page 519: ......

Page 521: ......

Page 533: ......

Page 537: ......

Page 539: ......

Page 540: ......

Page 541: ......

Page 542: ......

Page 543: ......

Page 544: ......

Page 545: ......

Page 546: ......

Page 547: ......

Page 548: ......

Page 549: ......

Page 550: ......

Page 551: ......

Page 552: ......

Page 553: ......

Page 554: ......

Page 557: ......

Page 558: ......

Page 559: ......

Page 560: ......

Page 561: ......

Page 562: ......

Page 563: ......

Page 564: ......

Page 565: ......

Page 566: ......

Page 567: ......

Page 568: ......

Page 569: ......

Page 570: ......

Page 571: ......

Page 572: ......

Page 573: ......

Page 575: ......

Page 577: ......

Page 578: ......

Page 579: ......

Page 580: ......

Page 581: ......

Page 582: ......

Page 583: ......

Page 585: ......

Page 587: ......

Page 589: ......

Page 591: ......

Page 593: ......

Page 595: ......

Page 596: ......

Page 597: ......

Page 598: ......

Page 599: ......

Page 600: ......

Page 601: ......

Page 602: ......

Page 603: ......

Page 604: ......

Page 605: ......

Page 606: ......

Page 607: ......

Page 608: ......

Page 609: ......

Page 610: ......

Page 611: ......

Page 612: ......

Page 621: ......

Page 622: ......

Page 623: ......

Page 624: ......

Page 625: ......

Page 626: ......

Page 627: ......

Page 631: ......

Page 633: ......

Page 634: ......

Page 637: ......

Page 638: ......

Page 639: ......

Page 640: ......

Page 641: ......

Page 645: ......

Page 646: ......

Page 647: ......

Page 648: ......

Page 649: ......

Page 650: ......

Page 651: ......

Page 657: ......

Page 659: ......

Page 661: ......

Page 662: ......

Page 663: ......

Page 667: ......

Page 668: ......

Page 671: ......

Page 672: ......

Page 673: ......

Page 677: ......

Page 678: ......

Page 679: ......

Page 680: ......

Page 681: ......

Page 682: ......

Page 683: ......

Page 684: ......

Page 685: ......

Page 686: ......

Page 689: ......

Page 691: ......

Page 693: ......

Page 695: ......

Page 696: ......

Page 699: ......

Page 701: ......

Page 703: ......

Page 705: ......

Page 706: ......

Page 707: ......

Page 711: ......

Page 712: ......

Page 715: ......

Page 716: ......

Page 719: ......

Page 721: ......

Page 722: ......

Page 725: ......

Page 727: ......

Page 728: ......

Page 731: ......

Page 733: ......

Page 734: ......

Page 737: ......

Page 739: ......

Page 741: ......

Page 742: ......

Page 745: ......

Page 747: ......

Page 749: ......

Page 751: ......

Page 753: ......

Page 754: ......

Page 755: ......

Page 756: ......

Page 757: ......

Page 758: ......

Page 759: ......

Page 763: ......

Page 764: ......

Page 765: ......

Page 766: ......

Page 767: ......

Page 768: ......

Page 769: ......

Page 770: ......

Page 771: ......

Page 772: ......

Page 773: ......

Page 774: ......

Page 775: ......

Page 776: ......

Page 777: ......

Page 778: ......

Page 779: ......

Page 780: ......

Page 781: ......

Page 782: ......

Page 783: ......

Page 784: ......

Page 785: ......

Page 786: ......

Page 787: ......

Page 788: ......

Page 789: ......

Page 790: ......

Page 791: ......

Page 792: ......

Page 793: ......

Page 794: ......

Page 795: ......

Page 796: ......

Page 797: ......

Page 798: ......

Page 799: ......

Page 800: ......

Page 801: ......

Page 802: ......

Page 803: ......

Page 804: ......

Page 805: ......

Page 806: ......

Page 807: ......

Page 835: ...Fig 7 Body Splices 8W 95 6 8W 95 SPLICE LOCATIONS JA DESCRIPTION AND OPERATION Continued ...

Page 837: ......

Page 975: ...Adapter 6887 Camshaft Seal Installer 6863 9 138 2 5L ENGINE JA SPECIAL TOOLS Continued ...

Page 1001: ...13 6 BUMPERS AND FRAME JA SPECIFICATIONS Continued ...

Page 1065: ...Fuel Line Adapter 1 4 14 64 FUEL SYSTEM JA SPECIAL TOOLS Continued ...

Page 1071: ......

Page 1236: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 105 SCHEMATICS AND DIAGRAMS Continued ...

Page 1237: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 106 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1238: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 107 SCHEMATICS AND DIAGRAMS Continued ...

Page 1239: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 108 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1240: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 109 SCHEMATICS AND DIAGRAMS Continued ...

Page 1241: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 110 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1242: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 111 SCHEMATICS AND DIAGRAMS Continued ...

Page 1243: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 112 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1244: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 113 SCHEMATICS AND DIAGRAMS Continued ...

Page 1245: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 114 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1246: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 115 SCHEMATICS AND DIAGRAMS Continued ...

Page 1247: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 116 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1248: ...41TE TRANSAXLE HYDRAULICSCHEMATIC JA TRANSAXLE 21 117 SCHEMATICS AND DIAGRAMS Continued ...

Page 1271: ......

Page 1287: ...SPECIFICATIONS SUNROOF COMPONENTS 23 16 BODY JA ...

Page 1318: ...SPECIAL TOOLS BODY REMOVER MOLDINGS C 4829 STICK TRIM C4755 JA BODY 23 47 ...

Page 1319: ......

Page 1321: ...Fig 1 Floor Console 23 2 BODY JA REMOVAL AND INSTALLATION Continued ...

Page 1359: ......

Page 1387: ......

Page 1401: ...FASTENER IDENTIFICATION 6 INTRODUCTION JA GENERAL INFORMATION Continued ...

Page 1404: ...METRIC CONVERSION JA INTRODUCTION 9 GENERAL INFORMATION Continued ...

Page 1512: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 105 SCHEMATICS AND DIAGRAMS Continued ...

Page 1513: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 106 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1514: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 107 SCHEMATICS AND DIAGRAMS Continued ...

Page 1515: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 108 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1516: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 109 SCHEMATICS AND DIAGRAMS Continued ...

Page 1517: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 110 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1518: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 111 SCHEMATICS AND DIAGRAMS Continued ...

Page 1519: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 112 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1520: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 113 SCHEMATICS AND DIAGRAMS Continued ...

Page 1521: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 114 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1522: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 115 SCHEMATICS AND DIAGRAMS Continued ...

Page 1523: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 116 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1524: ...41TE TRANSAXLE HYDRAULICSCHEMATIC JA TRANSAXLE 21 117 SCHEMATICS AND DIAGRAMS Continued ...